- Product Details

- {{item.text}}

Quick Details

-

Max. Spindle Speed (r.p.m):

-

2000 r.p.m

-

Spindle Bore(mm):

-

90

-

Width of bed (mm):

-

45 mm

-

Spindle Motor Power(kW):

-

22

-

Max. Turned Length (mm):

-

500

-

Travel (X Axis)(mm):

-

400 mm

-

Travel (Z Axis)(mm):

-

500 mm

-

Place of Origin:

-

Shandong, China

-

Dimension(L*W*H):

-

250*210*300

-

Brand Name:

-

HENGGA

-

Model Number:

-

LYV-SD500

-

Voltage:

-

380V

-

Weight (KG):

-

8500

-

Applicable Industries:

-

automobile spare parts

-

Marketing Type:

-

2023 Hot Product

-

Core Components:

-

principal axis

-

Product name:

-

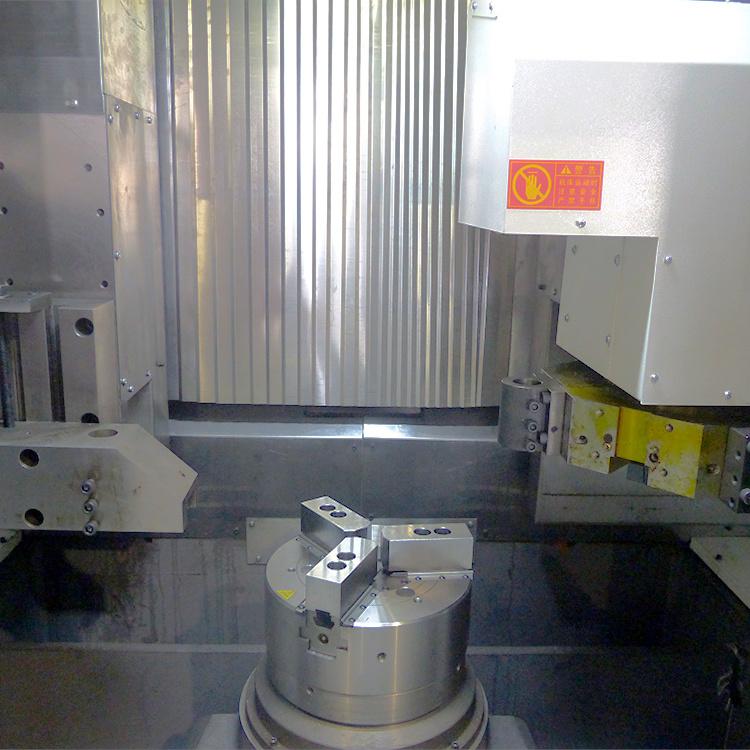

Double Tool Position CNC Vertical Lathe

-

Turret:

-

Row Cutter

-

Processing Diameter:

-

500mm

-

Shaft Runout:

-

0.008mm

-

X axis Positioning Precison:

-

0.01mm

-

X axis Repeated Positioning Precison:

-

0.007mm

-

Max. Speed:

-

2000rpm

-

X axis Stroke:

-

400mm

-

Z axis Stroke:

-

500mm

-

Main Motor:

-

22KW

Quick Details

-

Type:

-

VERTICAL

-

Max. Length of Workpiece (mm):

-

500mm

-

Year:

-

2023

-

Max. Spindle Speed (r.p.m):

-

2000 r.p.m

-

Spindle Bore(mm):

-

90

-

Width of bed (mm):

-

45 mm

-

Spindle Motor Power(kW):

-

22

-

Max. Turned Length (mm):

-

500

-

Travel (X Axis)(mm):

-

400 mm

-

Travel (Z Axis)(mm):

-

500 mm

-

Place of Origin:

-

Shandong, China

-

Dimension(L*W*H):

-

250*210*300

-

Brand Name:

-

HENGGA

-

Model Number:

-

LYV-SD500

-

Voltage:

-

380V

-

Weight (KG):

-

8500

-

Applicable Industries:

-

automobile spare parts

-

Marketing Type:

-

2023 Hot Product

-

Core Components:

-

principal axis

-

Product name:

-

Double Tool Position CNC Vertical Lathe

-

Turret:

-

Row Cutter

-

Processing Diameter:

-

500mm

-

Shaft Runout:

-

0.008mm

-

X axis Positioning Precison:

-

0.01mm

-

X axis Repeated Positioning Precison:

-

0.007mm

-

Max. Speed:

-

2000rpm

-

X axis Stroke:

-

400mm

-

Z axis Stroke:

-

500mm

-

Main Motor:

-

22KW

Products Description

Hengga LYV-SD500 high precision Car Disc Brake Drum Lathe Machine CNC Automatic Vertical Turning Lathe with turret

Main Features

1. The LYV-SD500 CNC vertical lathe is economical, efficient, energy-saving, and environmentally friendly, and is the first choice for processing complex disc and short shaft parts in automobiles, water pumps, motors, and other industries.

2. LYV-SD500 machine can be used to process the inner and outer cylindrical surfaces, conical surfaces, end surfaces, grooving and chamfering parts, especially suitable for rough and finish machining of all kinds of flange and various kinds of automobile wheel hubs, brake disc and drums, flywheel housings, clutch housings, clutch pressure plate type, shells, discs and etc.

3. It is mainly used to process large and heavy workpieces with large radial dimensions and relatively small axial dimensions and complex shapes, such as a variety of disc wheel and sleeve workpiece thread, arc, and the internal and external surfaces of the rotary body, end face, and groove.

4. LYV-SD500 Vertical Turning Lathe not only can easily satisfy the general components of turning processing, can also be equipped with double functions of the brake disc double-sided processing modular design at the same time, more extensive application fields.

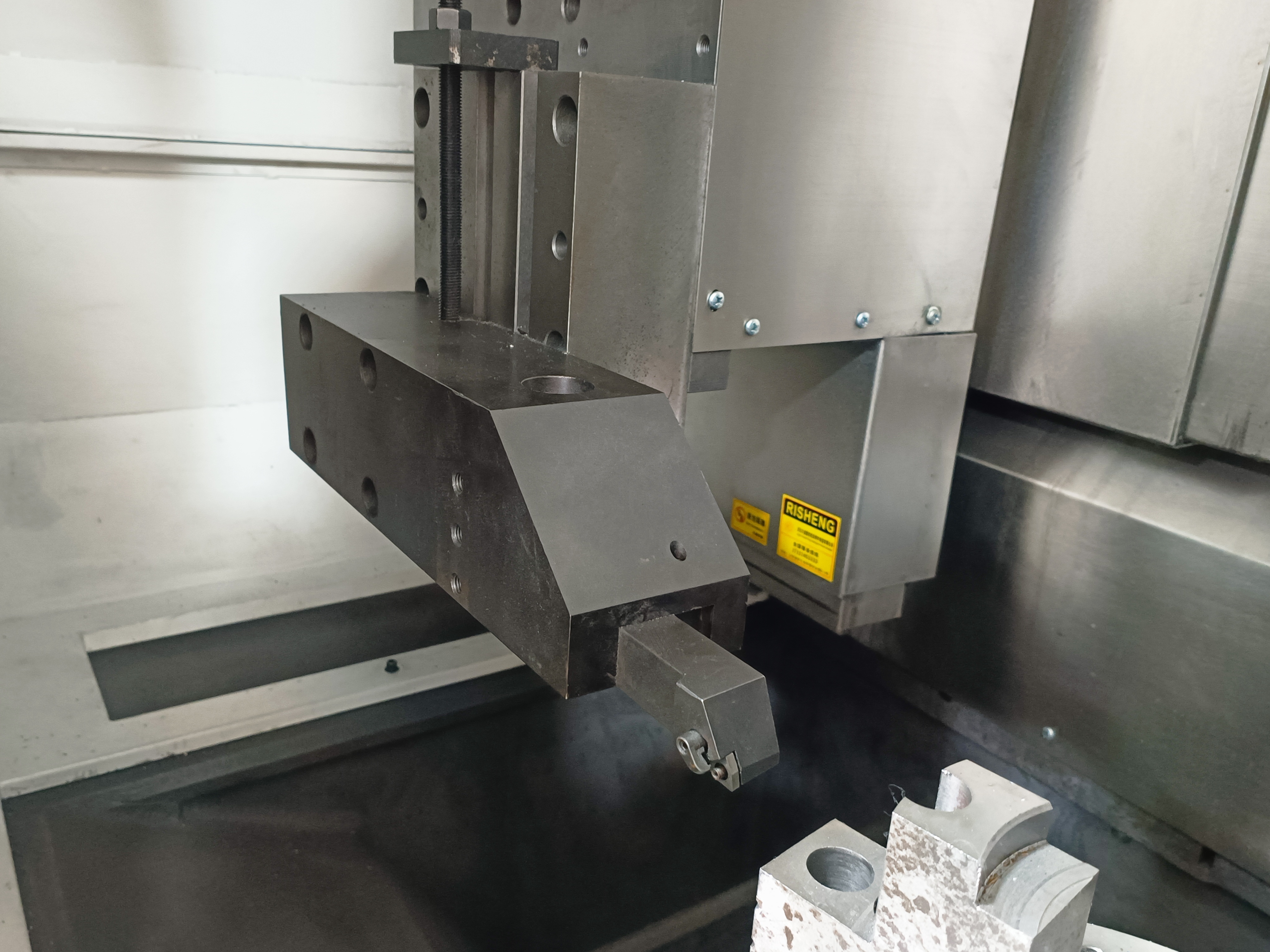

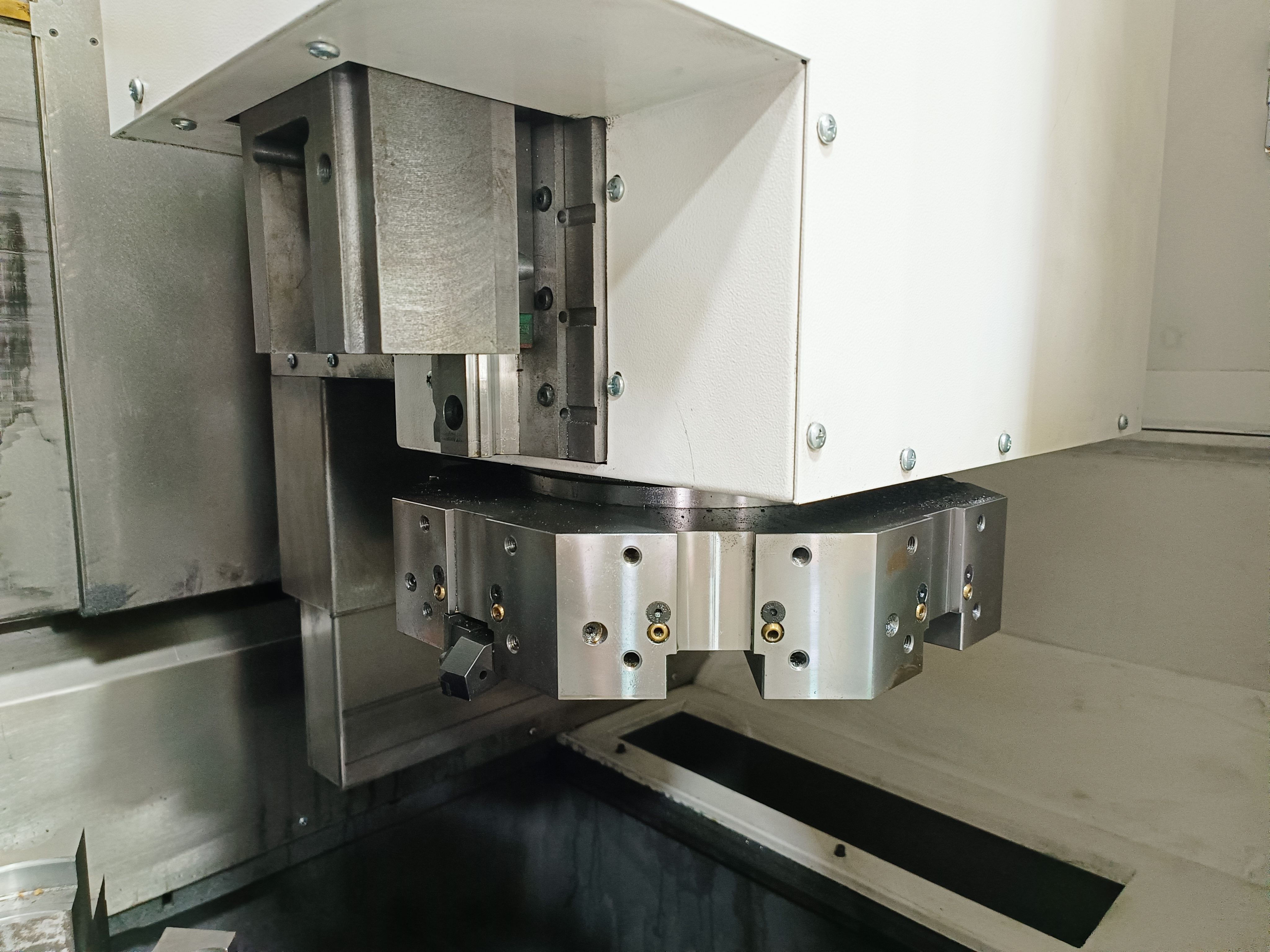

5. It has single spindle but dual-turret, controlling by dual-channel NC unit, one tooling holder and one 8-station servo turret

can feed separately and do cutting on internal and external surface of hubs. One control with two feeding system ensure high efficiency machining and small working space occupation.

6. With high speed indexing, providing consistent and most stable machining performance, this machine is most suitable for high-precision and automatic mass production and machining tough materials.

2. LYV-SD500 machine can be used to process the inner and outer cylindrical surfaces, conical surfaces, end surfaces, grooving and chamfering parts, especially suitable for rough and finish machining of all kinds of flange and various kinds of automobile wheel hubs, brake disc and drums, flywheel housings, clutch housings, clutch pressure plate type, shells, discs and etc.

3. It is mainly used to process large and heavy workpieces with large radial dimensions and relatively small axial dimensions and complex shapes, such as a variety of disc wheel and sleeve workpiece thread, arc, and the internal and external surfaces of the rotary body, end face, and groove.

4. LYV-SD500 Vertical Turning Lathe not only can easily satisfy the general components of turning processing, can also be equipped with double functions of the brake disc double-sided processing modular design at the same time, more extensive application fields.

5. It has single spindle but dual-turret, controlling by dual-channel NC unit, one tooling holder and one 8-station servo turret

can feed separately and do cutting on internal and external surface of hubs. One control with two feeding system ensure high efficiency machining and small working space occupation.

6. With high speed indexing, providing consistent and most stable machining performance, this machine is most suitable for high-precision and automatic mass production and machining tough materials.

Quick View List

|

Product Model

|

LYV-SD500 CNC Vertical Turning Lathe

|

|

Application Area

|

Flange

Brake Disc & Drums

Automobile Wheel Hubs

Flywheels

Clutch Plate and Housings

|

|

Processing Procedure

|

Rough And Finish Turning

Finish Turning Double Surface Of Workpiece

|

|

MOQ

|

1 Unit

|

|

Payment Terms

|

T/T, L/C, Paypal, Westunion, Alibaba.com Pay

30% in advance, 70% before shipping

|

|

Packaging Method

|

Wooden case(LCL) / Steel Pallet(FCL)

|

|

Leading Time

|

1 unit--45 days

2-5 units--60 days

>5 units--To be negotiated

|

Product Paramenters

Details Images

Recommend Products

Hot Searches