- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

LIONBALL

-

Model Number:

-

YWFB4E310

-

Voltage:

-

230V

-

Product name:

-

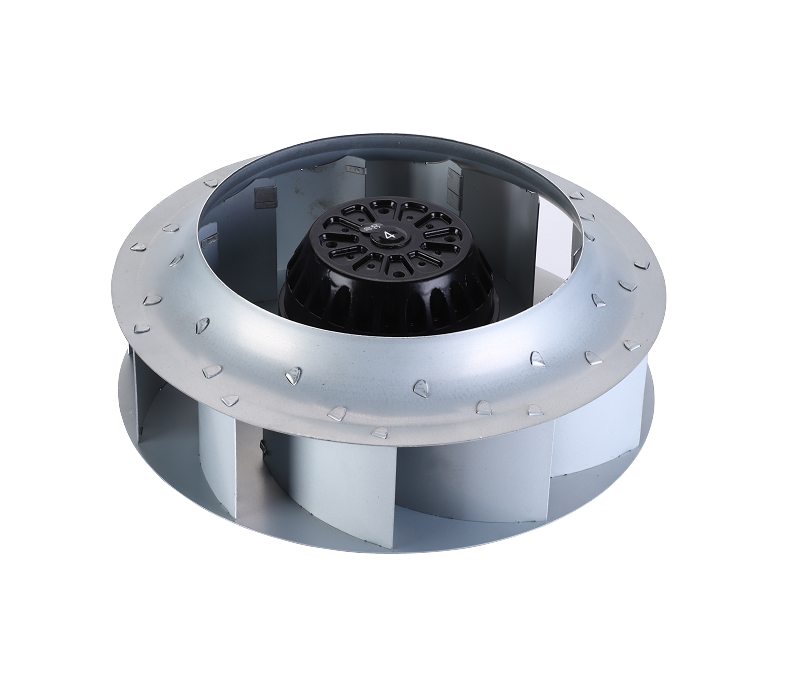

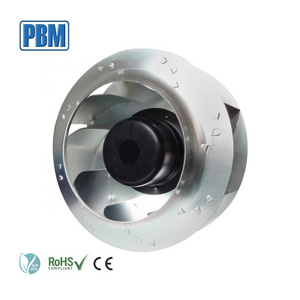

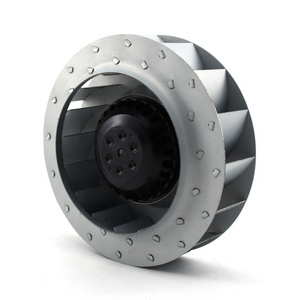

Backward curved centrifugal fan impeller for Ventilation system

-

rotation:

-

CW,CCW

-

protection class:

-

IP54 or IP44

-

fan blade:

-

sheet steel

-

impeller:

-

backward curved blades

-

bearings:

-

maintenance-free ball bearings

-

insulation class:

-

B or F

-

motor protection:

-

thermal protector

-

frequency:

-

50/60Hz

-

bearings life:

-

30,000hours

Quick Details

-

Applicable Industries:

-

Hotels, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other

-

Electric Current Type:

-

AC

-

After-sales Service Provided:

-

Video technical support

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

LIONBALL

-

Model Number:

-

YWFB4E310

-

Voltage:

-

230V

-

Product name:

-

Backward curved centrifugal fan impeller for Ventilation system

-

rotation:

-

CW,CCW

-

protection class:

-

IP54 or IP44

-

fan blade:

-

sheet steel

-

impeller:

-

backward curved blades

-

bearings:

-

maintenance-free ball bearings

-

insulation class:

-

B or F

-

motor protection:

-

thermal protector

-

frequency:

-

50/60Hz

-

bearings life:

-

30,000hours

Backward curved centrifugal fan impeller for Ventilation system

—Material: Impeller: sheet aluminum, welded

Rotor: Coated in black

—Number of blades: 6

—Direction of rotation: Clockwise, seen on rotor

—Type of protection: IP54 or IP44

—Insulation class: B or F

—Mounting position: Shaft horizontal or rotor on bottom; rotor on top on request(Any)

—Condensate discharges: Rotor-side

—Mode of operation: Continuous operation (S1)

—Bearings: Maintenance- free ball bearings

—Motor protection: Design with thermal overload protector

—Cable exit: variable, lateral

—Product conforming to standard: CE Approval

—Approval: UL Approval, CCC Certificate

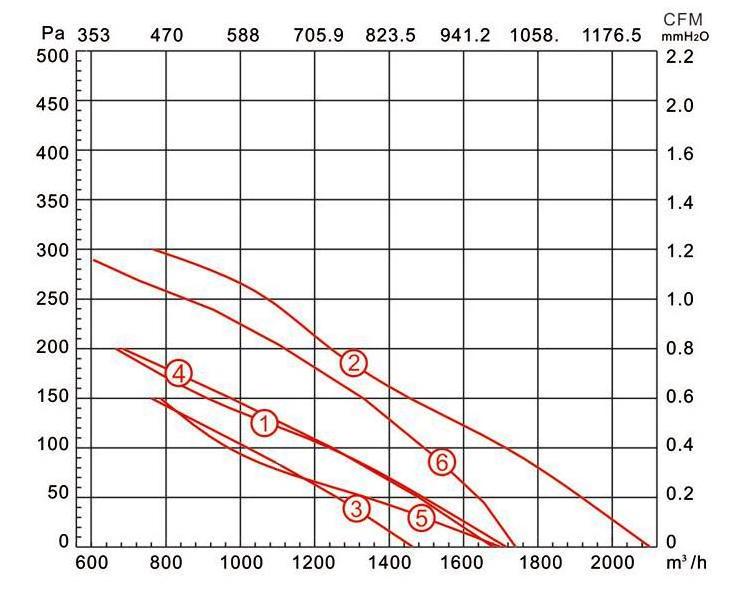

1. performance parameter

|

|

|

|

(A) |

|

|

FLOW

|

|

|

|

|

Science |

|

YWFB4E310 |

230 |

50 |

0.46 |

103 |

1360 |

1715 |

4 |

3 |

63 |

1 |

Sheel aluminium |

|

115 |

60 |

1.51 |

172 |

1650 |

2090 |

16 |

3 |

68 |

2 |

Sheel aluminium |

|

|

YWFB4E310L |

230 |

50/60 |

0.47/0.51 |

99/117 |

1340/1530 |

1465/1680 |

3 |

2 |

62/66 |

3 4 |

Sheel aluminium |

|

YWFB4E310H |

230 |

50 |

0.4 |

92 |

1270 |

1700 |

3 |

2 |

62 |

5 |

Sheel aluminium |

|

YWFB4D310 |

400 Y |

50 |

0.3 |

100 |

1420 |

1740 |

/ |

3 |

64 |

6 |

Sheel aluminium |

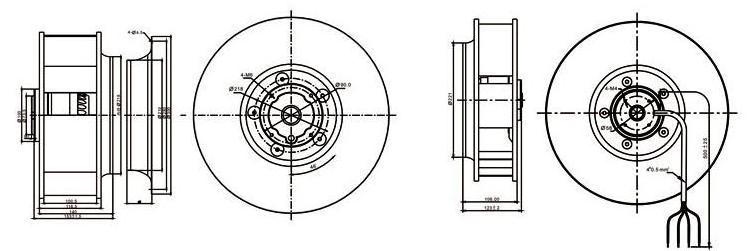

2. shape and the size of installation

3.air volume and static pressure curve

At LIONBALL, Our factory owns a group of high quality and hightech professional

designers and staff members.

NEW! Factory supply wheelchair motor of by superior products with preferential prices

WHY CHOOSE US?

1.Factory

2.Leading professional manufacturer of wheelchair motor.

3.Our factory owns a group of high quality and high-tech professional designers and staff members.

Our competitive Advantages of wheelchair motor

A) Cost advantage

We have our own workshop, metalprocess workshop and many other advanced machines. Key production parts are manufactured by ourselves.

B) Technological advantage

Our R&D center is provincial R&D Center. There are 4 Professor grade engineers and 6 senior engineers in our company.

C) Substantial experience and good service

We professionally produce motors and fans for more than 33 years. And we have done international trade for more than 10 years. So we can supply high quality products and services.

D) High cost performance

We have cost advantage, technological advantage and substantial experience. So our products have high cost performance. You can take the same cost purchase more better goods, or spend less for the same product.

Welcome to the world of motors and fans (Ningbo Lionball Ventilator Co., Ltd)

A)Have a glance at our Manufacturing facility of wheelchair motor

We have our own high speed punching machine, digital control machine, grinding macine, automatic coil winding machine, injection machine,and many other advanced equipments. Key production parts are manufactured by ourselves.

For more information, welcome to visit our company at any time.

We have our own workshop, metal processing workshop and many other advanced machines. Key production parts are manufactured by us.

Our R&D center is provincial R&D Center. There are 4 Professor engineers and 6 senior engineers in our company.

We professionally produce motors and fans for more than 33 years. And we have done international trade for more than 10 years. So we can supply high quality products and services.

We have cost advantage, technological advantage and substantial experience. So our products have high cost performance. You can take the same cost purchase more better goods, or spend less for the same product.

We have gotten VDE approval in Germany, UL approval in American, CE and ROHS approval in European, CCC safety certificate in China and ISO 9001:2008 certificate.As a promising company that has long history, our company has established well relationship with many renowned manufacturers and distributors. We expect to cooperate with more enterprise and believe that our high quality products and good service well bring win-win benefit between us.