- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

PPL-P0001

-

Product Name:

-

OEM Plastic Injection Molding Mols

-

Mould Material:

-

P20/718/718H/NAK80/S136/2738/2316

-

Product Material:

-

ABS, PP, Nylon, PC, POM, PA6, PA66, TPU, PE, PBT, ABS+PC

-

Drawing:

-

Provide by Customer(Stp/Step/Dxf/Dwg/Prt/Sat/Iges...)

-

Surface treatment:

-

Polishing, Texture, Painting etc.

-

Mould Life:

-

300000-500000 Shots

-

Cavity:

-

Single Cavity\ Multiple Cavity

-

Runner:

-

Hot Runner\ Cold Runner

-

Size:

-

According to the drawing

-

Service:

-

Customized OEM

Quick Details

-

Processing Service:

-

Moulding, CNC

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

PAPLER

-

Model Number:

-

PPL-P0001

-

Product Name:

-

OEM Plastic Injection Molding Mols

-

Mould Material:

-

P20/718/718H/NAK80/S136/2738/2316

-

Product Material:

-

ABS, PP, Nylon, PC, POM, PA6, PA66, TPU, PE, PBT, ABS+PC

-

Drawing:

-

Provide by Customer(Stp/Step/Dxf/Dwg/Prt/Sat/Iges...)

-

Surface treatment:

-

Polishing, Texture, Painting etc.

-

Mould Life:

-

300000-500000 Shots

-

Cavity:

-

Single Cavity\ Multiple Cavity

-

Runner:

-

Hot Runner\ Cold Runner

-

Size:

-

According to the drawing

-

Service:

-

Customized OEM

Advantages:

1.

Free design and free sample.

2.

Sign NDA.

3. ISO Certificated with the s

tr

ict quality control system

.

4. 10+ Years OEM&ODM Plastic Injection Molding experience.

5.

Good at spoken

english

and phone call communication.

6. One stop solution and drop shipment for online sellers.

| Product Description | OEM Plastic Injection Molding Parts |

| Plastic Materials | PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO,...etc. |

| Standard | ISO9001:2008 |

| Quality | RoHS and SGS standard |

| Feature | Non marking and Non flash |

| Size | According to your 2D, 3D Drawing |

|

Color,Quantity,Unit price, Tooling cost,Tooling size |

To be discussed |

| Package | Standard exported Wooden box packed, Fumigation process(upon required) |

| Mold Building Lead Time | T1, 15-25 Working days, Part measurement report (upon required). |

| Export Country | All countries are reachable. |

| Experience | 10+ years experience in plastic injection mold making and plastic prouducts produce. |

| Mould Base | Hasco Standard, European Standard, World Standard |

| Mould Base Material | LKM, FUTA, HASCO, DME,...etc. Or as per Customer's Requirment. |

| Surface Finish | Texture(MT standard), High gloss polishing,chrome plating |

| Cavity/Core Steel | P20, 718,718H, 2344, Starvax 420, S136, Nak80, etc. |

| Hot/ Cold Runner | HUSKY, INCOE, YDDO, HASCO, DME, MoldMaster, Masterflow, Mastip, Taiwan made brand, etc. |

| Mould Life | 5,000 to 1,000,000 Shots. (According to your working environment.) |

| Design & Program Softwares | CAD, CAM, CAE, Pro-E, UG, Soild works, Moldflow, CATIA....etc. |

| Equipments | High speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine for trial out mold from 50-3000T available. |

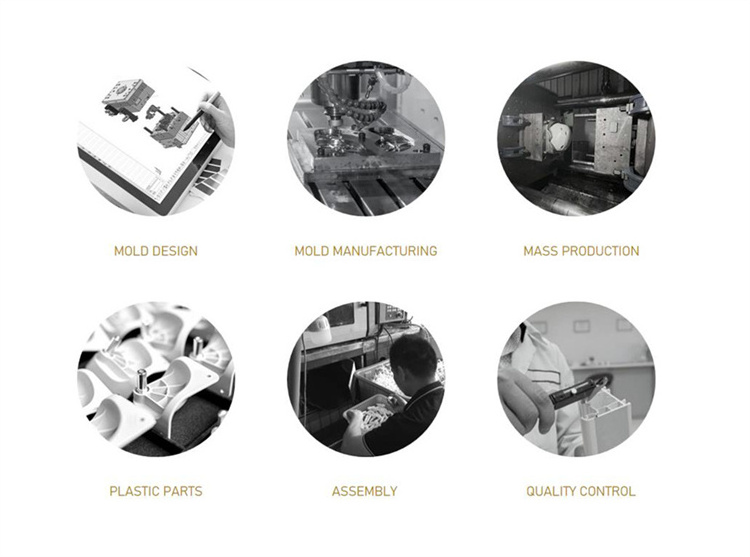

Papler Industry provides service of prototype making, mold design, mold production, mass production and assembly service in house. Our experience range from simple design to challenging technical parts.