- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Jinma

-

Dimension(L*W*H):

-

According to the model

-

Weight:

-

0.8 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Range of feed size:

-

210mm-1020mm

-

Range of discharge size:

-

10mm--300mm

-

Range of capacity:

-

1-500t/h

-

Material:

-

cast steel

-

Eccentric shaft:

-

40Cr

-

Motor:

-

Chinese famous brand or as required

-

Spare Parts Supply:

-

Any time supply

-

Performance:

-

Stable and reliable

Quick Details

-

Application:

-

Crush kinds of mining stone

-

Capacity(t/h):

-

10-300

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Jinma

-

Dimension(L*W*H):

-

According to the model

-

Weight:

-

0.8 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Range of feed size:

-

210mm-1020mm

-

Range of discharge size:

-

10mm--300mm

-

Range of capacity:

-

1-500t/h

-

Material:

-

cast steel

-

Eccentric shaft:

-

40Cr

-

Motor:

-

Chinese famous brand or as required

-

Spare Parts Supply:

-

Any time supply

-

Performance:

-

Stable and reliable

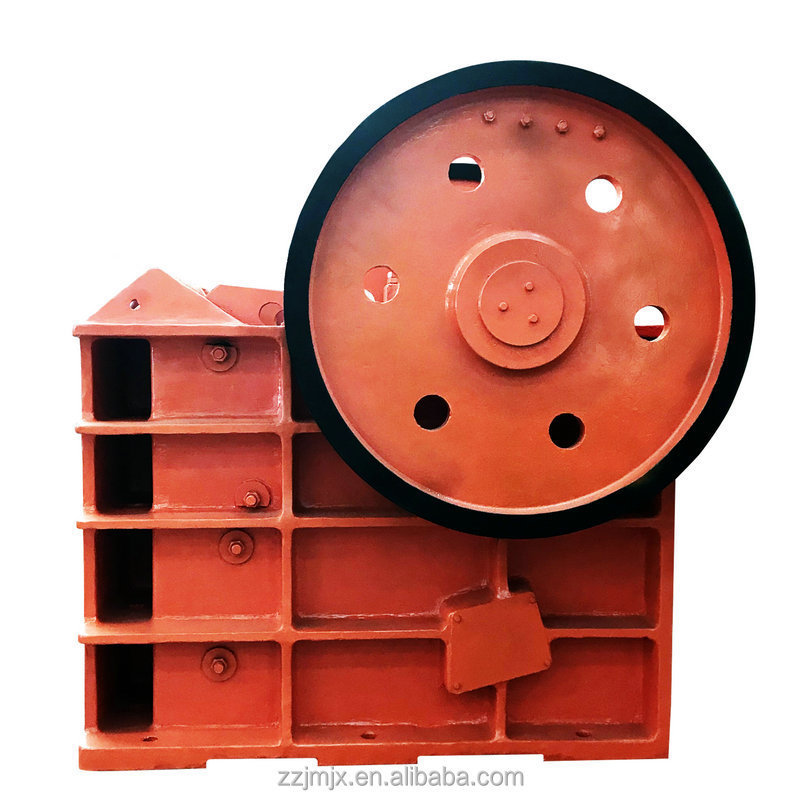

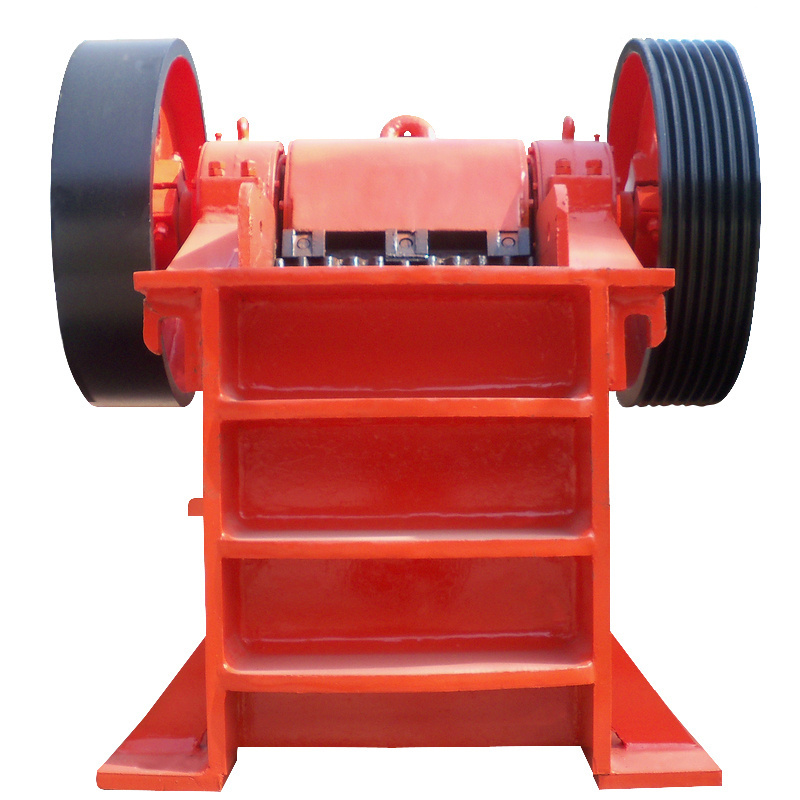

Stone Crushing Plant Used Small Jaw Crusher For Sale

Crushing machine features

1.Crushing Machine is used for crushing various of ores and rocks ,pressure below 320 MP

2. Mchine can crushing hard rocks of high erosion

3.Widely used for mining, smelting, building materials, road and railway construction, irrigation works, and materials

4. Crushing cavity is deep without dead zone. That improves the feeding capacity and through put;

5. Gasket discharge opening adjusting device enlarges adjustable range and increases the crusher's flexibility.

6. Reliable lubricating system, easy to replace components and maintain.

7. Simple structure, reliable working condition, low operation cost.

8. Energy saving: one jaw crusher can save energy of 15%-30%

9. Large adjustment range of discharge opening can meet different customers’ requirements

10. Low noise and less dust

Crushing machine produced by Jinma

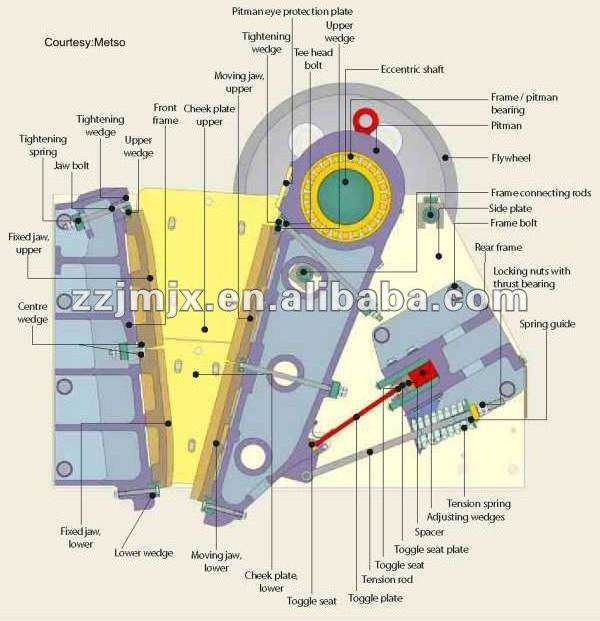

Crushing machine working principle:

The working principle of crushing machine is very simple. The whole crushing process rely on the relative motion of the two jaw plates. One of the jaw plates stay still while the other move against it. And with the movement, the materials between the two plates would be crushed into small elements. While the plates move against each other, the materials would be crushed and while plates move away from each other, the broken materials which are smaller enough would drop through the discharging opening. And due to the simple structure, Crushing machine is easy to maintain and repair. These features promote its popularity to a great extant.

The structure of jaw crusher

Note:stone production line provided by our factoryfor your reference:feeder-jaw crusher-conveyor-jaw crusher-conveyor-vibrating screen-conveyor

Jaw crusher specifications

|

Model |

Max feed size

|

discharge size

|

Capacity

|

Power (kw) |

Weight (T) |

|

PE150×250 |

125 |

10-40 |

1-3 |

5.5 |

0.8 |

|

PE200×300 |

180 |

20-70 |

2-8 |

11 |

1.4 |

|

PE250×400 |

210 |

20-80 |

5-20 |

15 |

3 |

|

PE400×600 |

350 |

40-100 |

15-60 |

30 |

6.5 |

|

PE500×750 |

425 |

50-100 |

40-110 |

55 |

11.3 |

|

PE600×900 |

480 |

65-160 |

90-150 |

75 |

17.625 |

|

PE750×1060 |

630 |

80-160 |

100-250 |

90-110 |

27.5 |

|

PE900×1200 |

750 |

95-165 |

120-300 |

110-160 |

52 |

|

PE1000×1200 |

850 |

110-260 |

180-350 |

110-160 |

57 |

|

PE1200×1500 |

1020 |

150-300 |

300-500 |

180-220 |

100 |

|

PEX150×750 |

120 |

8-25 |

10-40 |

15 |

3.5 |

|

PEX250×750 |

210 |

12-25 |

15-50 |

30 |

5.5 |

|

PEX250×1000 |

210 |

12-50 |

30-95 |

37 |

6.37 |

|

PEX250×1200 |

210 |

12-65 |

40-100 |

37 |

8.75 |

|

PEX350×750 |

300 |

15-50 |

20-50 |

30 |

6.5 |

|

PEX300×1300 |

250 |

20-90 |

45-130 |

75 |

11 |

the diesel engine jaw crusher produced by jinma

the spare parts

Packaging Details:

1. Main machine is packed with plastic wrap or steel box, depends on machine weight.

2. Electric motor is packed with steel box or wood box.

3. Motor control is packed with carton box.

4. Loaded container at factory.

Delivery Detail:

in 7 working days after down payment

Technological support:

Jinma insists on providing clients with overall solutions from equipment recommendation to debugging and installation, worker training, technical support and maintenance.

Our high reputed engineers and technicians can provide users with overall technical support, including material characteristic analysis, crushing test and process optimization of flow simulation.

Our professional engineers will design the most reasonable scheme for the real production line.