- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3000*800*1400

-

Name:

-

Squeezer granulator machine

-

Final product:

-

Granules

-

Keyword:

-

Film squeezer granulator

-

Capacity:

-

300kg/h

-

Power:

-

75kw

-

Color:

-

Blue

-

Screw and barrel material:

-

38CrMoAIA

-

Screw diameter:

-

300mm

-

Applied material:

-

PP PE wet films

-

Final Moisture of PP/PE scraps:

-

≤2-3%

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sevenstars

-

Weight (KG):

-

3000

-

Dimension(L*W*H):

-

3000*800*1400

-

Name:

-

Squeezer granulator machine

-

Final product:

-

Granules

-

Keyword:

-

Film squeezer granulator

-

Capacity:

-

300kg/h

-

Power:

-

75kw

-

Color:

-

Blue

-

Screw and barrel material:

-

38CrMoAIA

-

Screw diameter:

-

300mm

-

Applied material:

-

PP PE wet films

-

Final Moisture of PP/PE scraps:

-

≤2-3%

Product Description

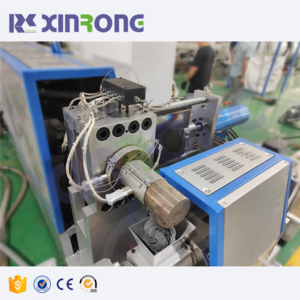

Granulator type waste wet plastic PP PE film recycling squeezer plant drying machine

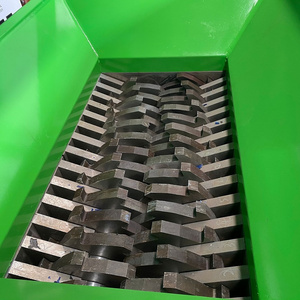

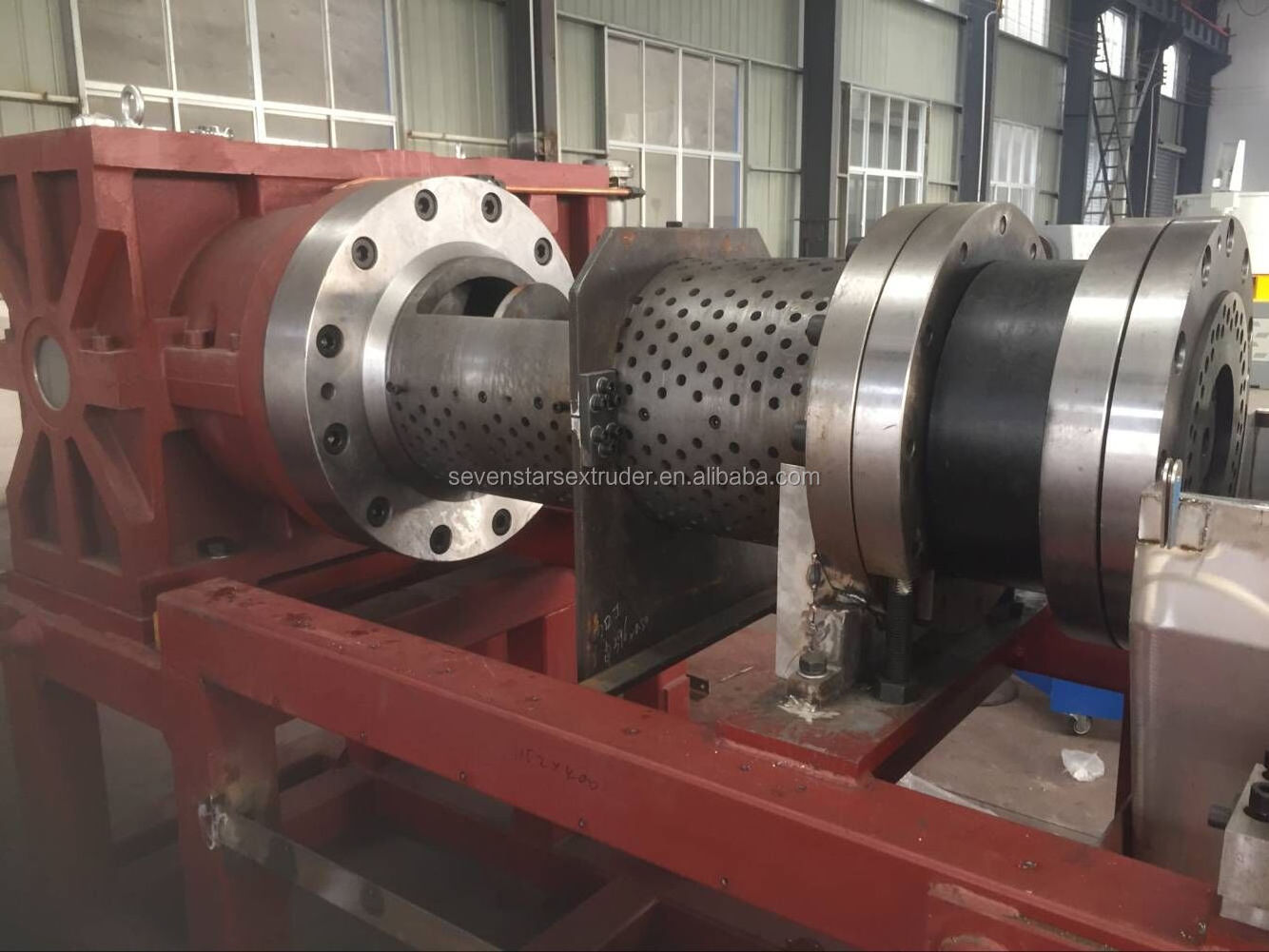

This Wet film scrap squeezer dryer plastic granulator machine is used after the plastic film/plastic agricultural film/PP woven bags/Space bag/tons bags/thin waste plastics plastic sheets washed,using the squeeze dewatering principle,squeeze the water from the plastic by rotating screw.The water will flow out from the bottom,the plastic will get hot by high intensity extrusion friction,and will plasticizing mildly after the mould heating.Finally the blade will cut the granules from the mould.

Advantage of squeezer dryer plastic machine:

1. Low power consumption. Main motor power between 90kw, no need to connection drying pipe system. Compare transitional horizontal dewatering machine+drying pipe system, can save power 40-50%

2. Small land occupied

3. Low rotation speed, almost no noise

4. Dewatering function is better, final products humidity less then 3%

5. After squeeze dry granulating machine, the material can put into granulator driectly, do not need the forced feeding machine.

6. Mechanical squeeze dewatering, compared with the original hot air drying, do not need use dewatering machine, drying system and the agglomerator machine, it can save the energy greatly.

1. Low power consumption. Main motor power between 90kw, no need to connection drying pipe system. Compare transitional horizontal dewatering machine+drying pipe system, can save power 40-50%

2. Small land occupied

3. Low rotation speed, almost no noise

4. Dewatering function is better, final products humidity less then 3%

5. After squeeze dry granulating machine, the material can put into granulator driectly, do not need the forced feeding machine.

6. Mechanical squeeze dewatering, compared with the original hot air drying, do not need use dewatering machine, drying system and the agglomerator machine, it can save the energy greatly.

Specification

|

Model

|

BDX300

|

BDX500

|

BDX800

|

|

Main motor power(kw)

|

55 or 75

|

90 or 110

|

132 or 160

|

|

Capacity(kg/h)

|

300

|

400-500

|

500-800

|

|

Screw and barrel material

|

38CrMoAIA

|

38CrMoAIA

|

38CrMoAIA

|

|

Screw diameter(mm)

|

250

|

300

|

380

|

|

Applied material

|

PP PE wet films

|

PP PE wet films

|

PP PE wet films

|

|

Final Moisture of PP/PE scraps

|

≤2-3%

|

≤2-3%

|

≤2-3%

|

|

Final product

|

Granules

|

Granules

|

Granules

|

Packing & Delivery

SEA WORTHY PACKING OR WOODEN BOX PACKING

Hot Searches