Meet the demand of mass production and large size cutting sheet.

Working area : 1600*1200mm.

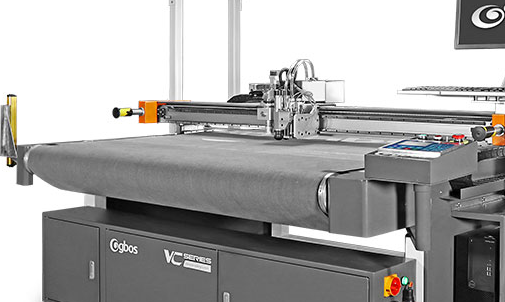

Gbos CNC VC9 Oscillating knife cutting machine use of the principle of the blade with rapid vibration to cut the material to meet the leather products cutting needs. GBOS LASER is committed to building the one-stop intelligent cutting solutions for shoes industries.

|

GBOS Oscillating Knife Cutting Machine

|

|

|

|

|||

|

MODEL

|

|

VC9-1612-ITS2

|

|

|||

|

Processing Area(mm)

|

|

1600×1200mm

|

|

|||

|

Gross Power(W)

|

|

2300W

|

|

|||

|

Measurement(mm)(L×W×H)

|

|

2180×2380×1250mm

|

|

|||

|

System/Compatible Format

|

|

Windows XP/7/8/10,AI,PLT,DXF,DST,DSB

|

|

|||

|

Weight(KG)

|

|

580KG

|

|

|||

|

Power Supply

|

|

380VAC,50Hz /40A

220VAC,50Hz /20A

|

|

|||

|

Max cutting speed(mm/s)

|

|

1000mm/s

|

|

|||

|

Acceleration(mm/s)

|

|

3000-5000mm/s

|

|

|||

|

CCD/SCCD Visual positioning/projector

|

|

Optional

|

|

|||

|

Electric knife, pneumatic knife double design

|

|

Standard electric

|

|

|||

GBOS oscillating knife cutting machine applicable materials

Suitable for genuine leather, synthetic leather, PU, fabric, EVA, TPU, insole, bags, belt, etc.

Meet the demand of mass production and large size cutting sheet.

Working area : 1600*1200mm.

With electric oscillating head and high speeds separate punching device, s ave time for making the die cutting mould, quikly respond to market reaction.

Partitioned vacuum system is suitable for any kind of materials.

It can effectively fix the material.

Ensure cutting quality.while also having energy saving design.

This feature is more reasonable compared with the normal patterns arranging.

It's easier to operate and waste saving.it's capable of arranging odd number of patterns, cutting leftover materials and divided cutting of large pattern.

One key nesting for multi sizes

Automatic separation, different colors for each size

Count automatically according to the layers of materials

For Genuine leather, this function can a

utomatic detect and avoid defect on the leather during nesting and cutting, that could save much material and reduce wastage

Instant Preview of Nesting Effects - convenient, fast.

Gbos Laser IOT system smartly monitor every machine by remote diagnosis, remote control, auto updating of software and online information transfer etc.

Since it was established in 2005, GBOS Laser Brand has been devoted to the research and development, innovation, production and sales of medium and high-end laser systems. So far, it has launched more than 150 kinds of intelligent laser systems, and product lines cover laser marking, cutting, drilling, engraving and other fields. The company has passed the industry's ISO9001.2008 quality management standard and its core technology has won several national patents and software copyrights. A number of products have passed the EU CE certification.

The company's core technology, talent, and innovation have created the most comprehensive product line of laser systems in the industry. As the industry leader in intelligent laser systems, our laser systems are being used in various countries and regions worldwide, and customers range from small family-owned businesses to large highly automated enterprises. We believe that our leading laser system can help you to develop and maintain a competitive advantage.

✔Free sample testing

✔Professional introduction

✔Multilingual o nline services

✔Warranty available and prompt delivery

✔Free technical training and software upgrading

✔Remote control and local installation

✔Machine maintenance

1.Is there any technical help after we receive GBOS oscillating knife cutter?

Yes, we have perfect after-sale service team to supply technical support on our customers. Our technical can assist you to install machine and give you free training after you receive machine.

2. What value can this oscillating knife cutting machine bring to me?

This system is suitable for mass production, small quantity orders, sample development and other applications. It solves the problem of data with not compatible format, complicated manual operations and untimely after-sales service.Create a one-stop automatic intelligent cutting.

3. What is the maximum cutting thickness of this CNC

oscillating

machine ?

For Hard material: the maximum cutting thickness is 4mm, supports multi-layer cutting up to 4mm,Suit for small size or large cutting.

4.If there is some problems about machine parts during warranty period, will your company repair or replace for me?

Yes, we will. Please send the main part back to our company,we will repair and send back them to you for free within warranty time. If the problem part can not be repaired well ,we will send new one to you within warranty time for free.

PS:Not including the consumable parts and Man-made damage.

Any problem, please do not hesitate to contact us, we will service to you at 7*24 hours.