- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Bianpu

-

Voltage:

-

220V-380V

-

Power:

-

90KW

-

Weight (KG):

-

800

-

After-sales Service Provided:

-

Online Support

Quick Details

-

Machine Type:

-

powder coating machine, Spray Booths, Coating Equipment

-

Marketing Type:

-

Hot Product

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Bianpu

-

Voltage:

-

220V-380V

-

Power:

-

90KW

-

Weight (KG):

-

800

-

After-sales Service Provided:

-

Online Support

- It supplies DC power for spraying gun, double IGBT module, intelligent module control, water-cooled electrical module, soft arcing, small size, high efficiency, low power consumption, good heat dissipation, low fault for continuous working, double protection system for water flow and temperature. Optical fiber communication, independent alarm system. It displays alarm codes for different faults of the power supply, and is the most stable plasma DC power supply currently in China.

-

This control cabinet adopts the latest generation of control terminal, which uses the current high-tech to automatically control the whole spraying system. All gases adopt the closed-loop control of imported flow controller, that solves the phenomenon of large of small plasma flame flow and also high or low voltage caused by unstable pressure and flow of gas in operation, thereby stabilizing the output power. It uses touch control terminal, full digital touch screen control, also can be directly entered through the touch screen for current, main gas, secondary gas and spraying parameters. It can store, call up the spraying parameter formula; the spraying parameters can be real-time record and curve saving(touch screen with memory card, power off saving) during the spraying process, and then get into the system which is divided into administrator and employee channels. Administrators can change and save spraying parameter formulas, employees can only call up spraying parameter formulas. And add on/off purification program(purification time in 10 seconds).

Independent movable control terminal. The gas pipeline is used stainless steel pipe, ferrule connection, good sealing, good look. The control adopts Siemens PLC, fully imported flow controller, imported brand pressure sensor, 12-inch touch screen control; multiple protection against high-frequency interference measures, fully digital touch screen control.

No. Items Parameters 1 control system Siemens PLC, MFC, touch screen 2 Main gas and pressure Argon or Nitrogen(0.7-0.8MPa) 3 Secondary gas and pressure Helium(0.4MPa) 4 Nitrogen pressure 0.6MPa 5 gas using method Argon, Argon+Nitrogen 6 MFC error ±0.1% F.S 7 Argon control 90L imported MFC 8 Nitogen control 20L improted MFC -

Nitrogen or Argon as the power feeding gas, the powder is transported to the outlet through the rotation of the powder feeding scraper, the powder leaves the feeding barrel into the spray gun through the gas pressure. The feeding barrel adopts visual plexiglass material. The feeder is independent control system, Siemens PLC, Siemens touch screen, imported flow controller and servo motor. The flow rate of powder feeding gas and feeding speed can be directly input through the touch screen, the speed is accurate to 0.1r/min, and the speed of agitator is adjustable

No. Items Parameters 1 Control system Siemens PLC, touch screen 2 Powder bucket capacity 3.0L*2 3 powder feeding gas Argon or Nitrogen 4 pressure of feeding gas 0.5-0.6MPa 5 Powder feeding speed 0-180g/min 6 powder feeding error ±1% 7 powder diameter -150~+400 Mesh 8 Mass Flowmeter 25L/min, ALICAT 9 Dimension 800*460*1400mm

-

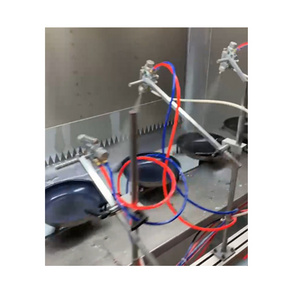

Mixing the water and electricity to getting into spray gun, and meanwhile supplying the required high-frequency pulse voltage when the spray gun starting to spray arcing light. it’s light and flexible, and convenient to drag. Good arcing performance, reducing the transient current shock when nozzle is arcing and anti-interference.

-

spray gun is used for thermal spraying, It can shorten spraying time, reduce processing costs and easy to replace.

- The chiller is used for cooling the spray gun and power supply, dual-way water cooling system. Two water-cooled pipes and water pressure can be adjustable separately.

-

Equipment Commission

- Upon request, We can dispatch one or two technician (s) to customer’s factory for commissioning.

- We can supply the video of installation and commissioning for equipment and also guide Customer that how to operation until equipment working in good condition.

- Support Customer dispatch their technician to come to our factory for free learning of equipment operation.