- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99%

-

Voltage:

-

220/380v

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

AQUA Juice Bottling Plant

-

Dimension(L*W*H):

-

By order

-

Weight:

-

1500-12000KG

-

Keyword:

-

Juice Bottling Plant

-

Control:

-

PLC

-

Capacity:

-

2000-12000BPH

-

Power:

-

220/380v

-

Quality:

-

High Quality Juice Bottling Plant

-

Material:

-

SS304

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Egypt, Canada, Turkey, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Indonesia, Mexico, Russia, Thailand, Japan, Malaysia, Morocco, Kenya, Argentina, South Korea, Chile, Colombia, Algeria, Romania, Kazakhstan

-

After-sales Service Provided:

-

Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

-

Certification:

-

CE,ISO

-

Marketing Type:

-

stable

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH, 500BPH, 2000BPH, 1000BPH

-

Packaging Material:

-

Plastic

-

Filling Material:

-

Beer, Milk, Water, Juice

-

Filling Accuracy:

-

99%

-

Voltage:

-

220/380v

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

AQUA Juice Bottling Plant

-

Dimension(L*W*H):

-

By order

-

Weight:

-

1500-12000KG

-

Keyword:

-

Juice Bottling Plant

-

Control:

-

PLC

-

Capacity:

-

2000-12000BPH

-

Power:

-

220/380v

-

Quality:

-

High Quality Juice Bottling Plant

-

Material:

-

SS304

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

Egypt, Canada, Turkey, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Indonesia, Mexico, Russia, Thailand, Japan, Malaysia, Morocco, Kenya, Argentina, South Korea, Chile, Colombia, Algeria, Romania, Kazakhstan

-

After-sales Service Provided:

-

Online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

-

Certification:

-

CE,ISO

-

Marketing Type:

-

stable

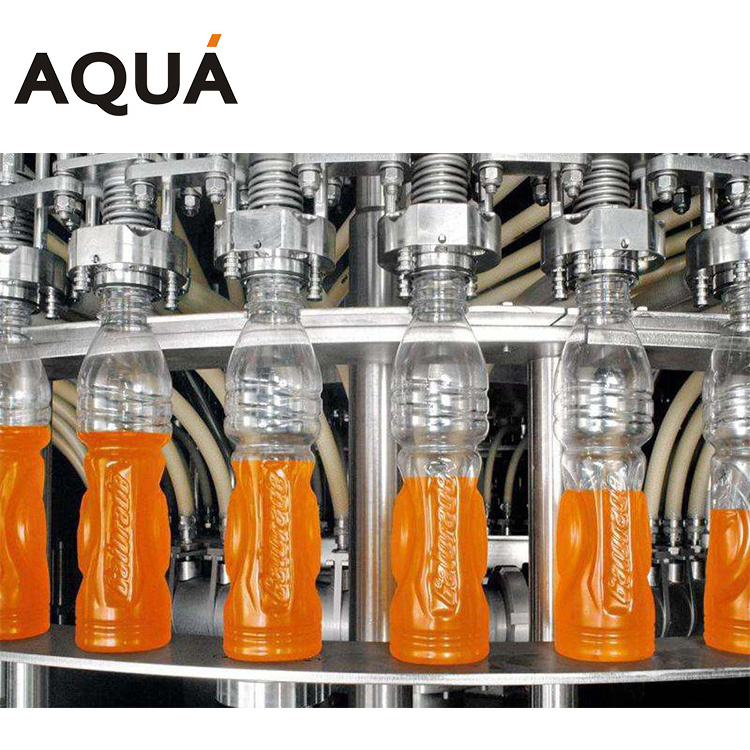

Integrated lemonade/orange fruit juice bottling plant/filling machine/production line

1. Product: Bottled Juice/Tea

2. Suitable bottle: 0.25-2L

3. Authentication: ISO,CE

1).The juice bottling plant is mainly used for bottling juice ,such as apple juice ,mango juice,orange juice,and other fruit juice.It can also be used for bottling water ,such as pure water and mineral water.

2).The juice bottling plant include washing part ,filling part,and sealing part,all of the process is automatic.

3). The juice bottling plant adopts hanging type conveying-bottle structure to make changing bottle model more convenient, faster and more east.

4). The advanced OMRON programmed controller (PLC) is adopted to control the machine to run automaticly

5). Transducer is uesd in bottle entering chains to adjust speed to make the operation of moving bottle steadily and reliably.

6). The juice bottling plant is convenient to operate with higher auromation because everypart of the machine is inspected to run with photo electicity.

Technical Data Of Juice Bottling Plant

|

Model |

CGF R 8-8-3 |

CGF R 12-12-5 |

CGF R 16-12-6 |

CGF R 18-18-6 |

CGF R 24-24-8 |

CGF R 32-32-10 |

CGF R 40-40-12 |

CGF R 50-50-15 |

|

Washing No |

8 |

12 |

16 |

18 |

24 |

32 |

40 |

50 |

|

Filling No |

8 |

12 |

12 |

18 |

24 |

32 |

40 |

50 |

|

Capping No |

3 |

5 |

6 |

6 |

8 |

10 |

12 |

15 |

|

Production Capacity(500ml) |

2000 BPH |

3000 BPH |

4 000BPH |

6 000BPH |

8000BPH |

12000 BPH |

15000 BPH |

18000 BPH |

|

Install Capacity(KW) |

3.0 |

3.5 |

3.5 |

4 |

4.8 |

7.6 |

8.3 |

9.6 |

|

Total weight(kg) |

1500 |

2200 |

2500 |

3500 |

5500 |

8000 |

10000 |

12000 |

|

Overall size |

1 900 *1 420 *2 000 |

2 200 *1 600 *2 300 |

2450 * 1800 * 2400 |

2650 * 1900 * 2400 |

2900 * 2100 * 2400 |

4100 * 2400 * 2400 |

4550 * 2650 * 2400 |

5450 * 3210 * 2400 |

Pictures Of Juice Bottling Plant

l Stainless steel construction, fine which gives excellent appearance and can be easily disinfected.

l Tempering glass window, clear and steadily

l Excellent start wheel design to making it easily when needs to change machine height when bottles sizes are changed.

l Machine Base with process of three layers Antirust Pain ensure the forever antirust

l All seal where liquid may Leakage & b ase neck come with rubber, water proof

A) Juice Bottling Plant -- Washing Part

l All 304 stainless steel rinser heads, water spray style inject design, more save water consumption & more clean

l 304 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

B) Juice Bottling Plant--Filling Part

l The filling station using all metal (not plastic) 304 stainless steel contact parts gives consistent accurate, high precision filling nozzle together with vacuum pump regurgitant system, to ensure the high filling precision, ensure same filling level

l Filling temperature is adjustable.

l Centre 304L stainless steel filling nozzle used which are designed for maximum flow rate and minimum bottle distortion during filling.

l All 304 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

C) Juice Bottling Plant--Capping Part

l Place & capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

l All 304stainless steel construction

l Automatic stop when lack of caps

D) Juice Bottling Plant--Electric System

l When accident system automatic stop & alarm

l Emergency switch when accident