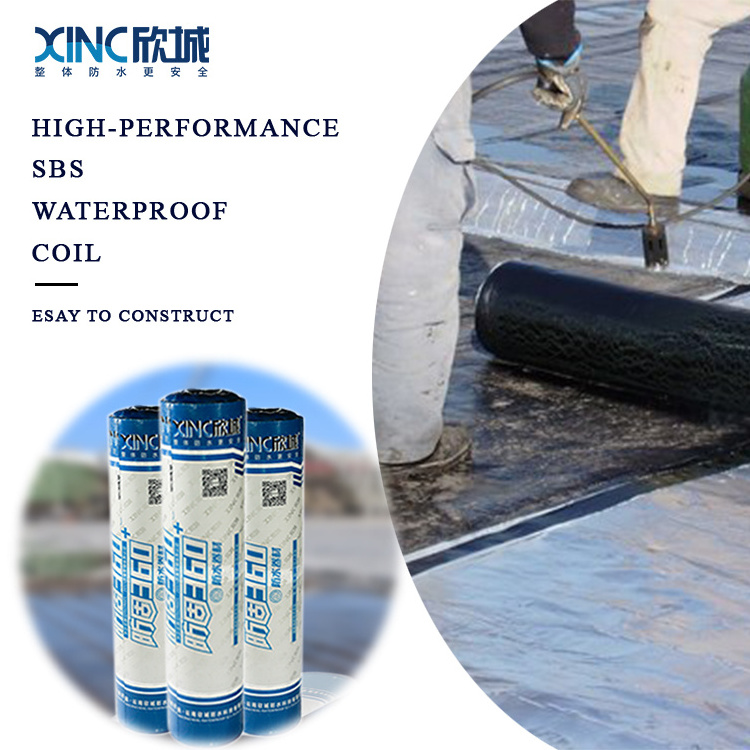

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Waterproof for Roof

-

Design Style:

-

Traditional

-

Place of Origin:

-

Yunnan, China

-

Brand Name:

-

XINC

-

Model Number:

-

FG360-SBS-AF-1

-

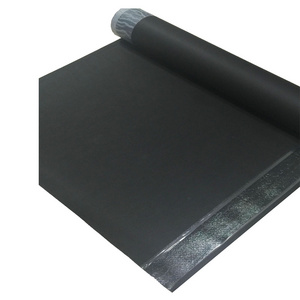

Type:

-

Waterproof Coil

-

Product Name:

-

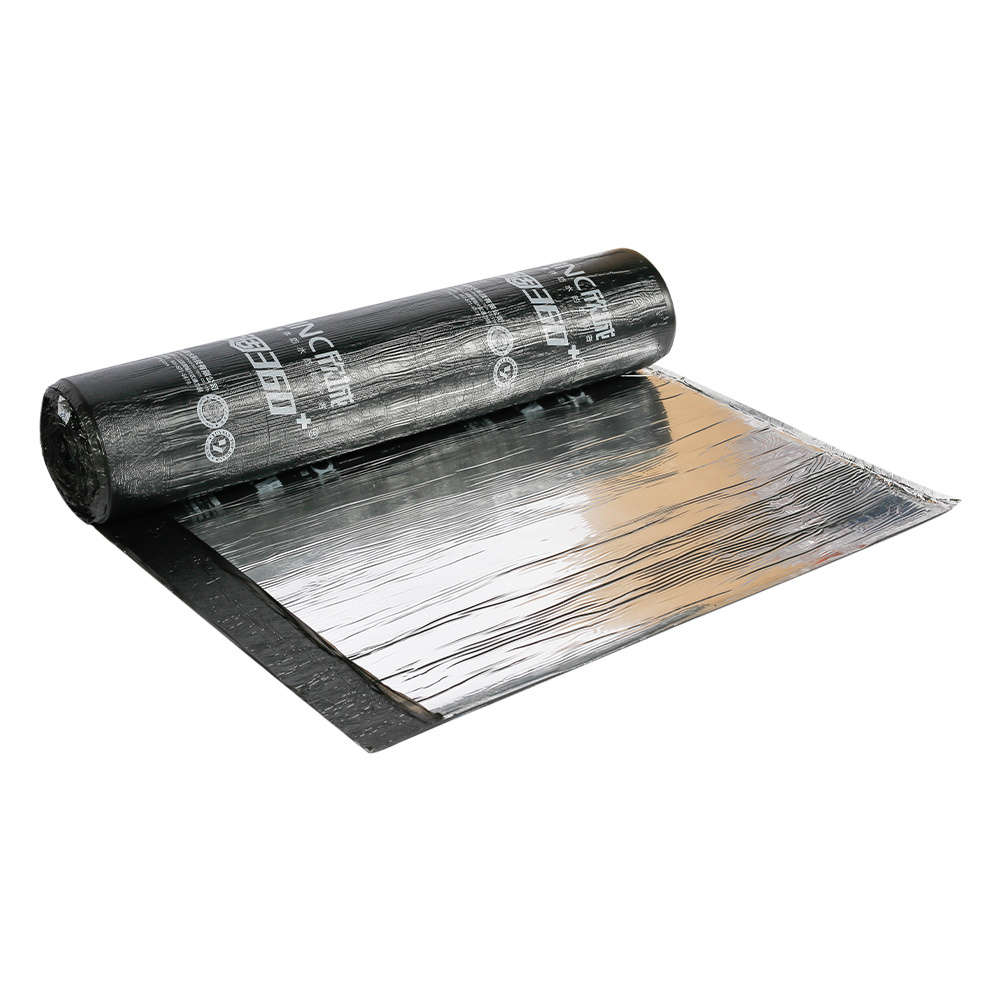

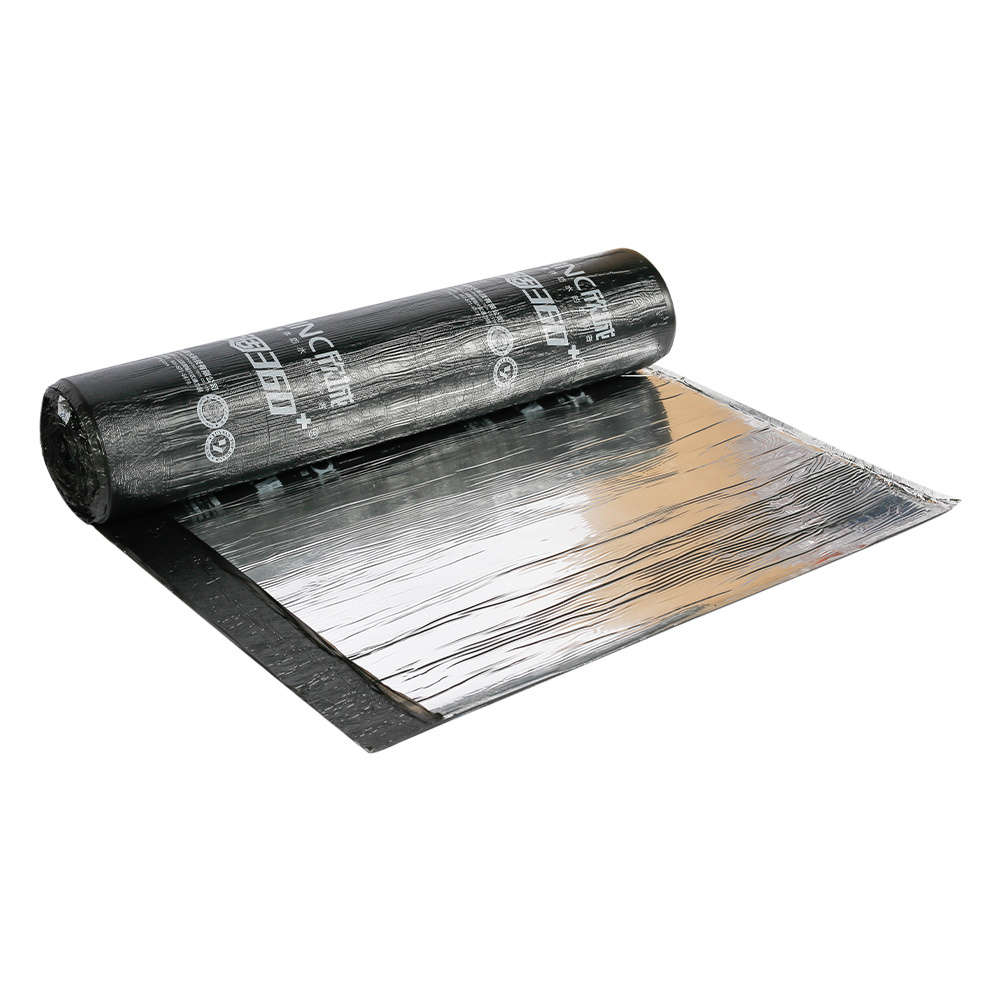

SBS Modified Bitumen Waterproof Membrane

-

Material:

-

SBS Modified Bitumen

-

Thickness:

-

3.mm

-

Width:

-

1.0m

-

Length:

-

10m

-

Certificate:

-

CE ISO9001

-

Keyword:

-

SBS Waterproof Memebrane

-

Packing:

-

100sqm/roll Wrapped

-

Weight:

-

63kg/roll

-

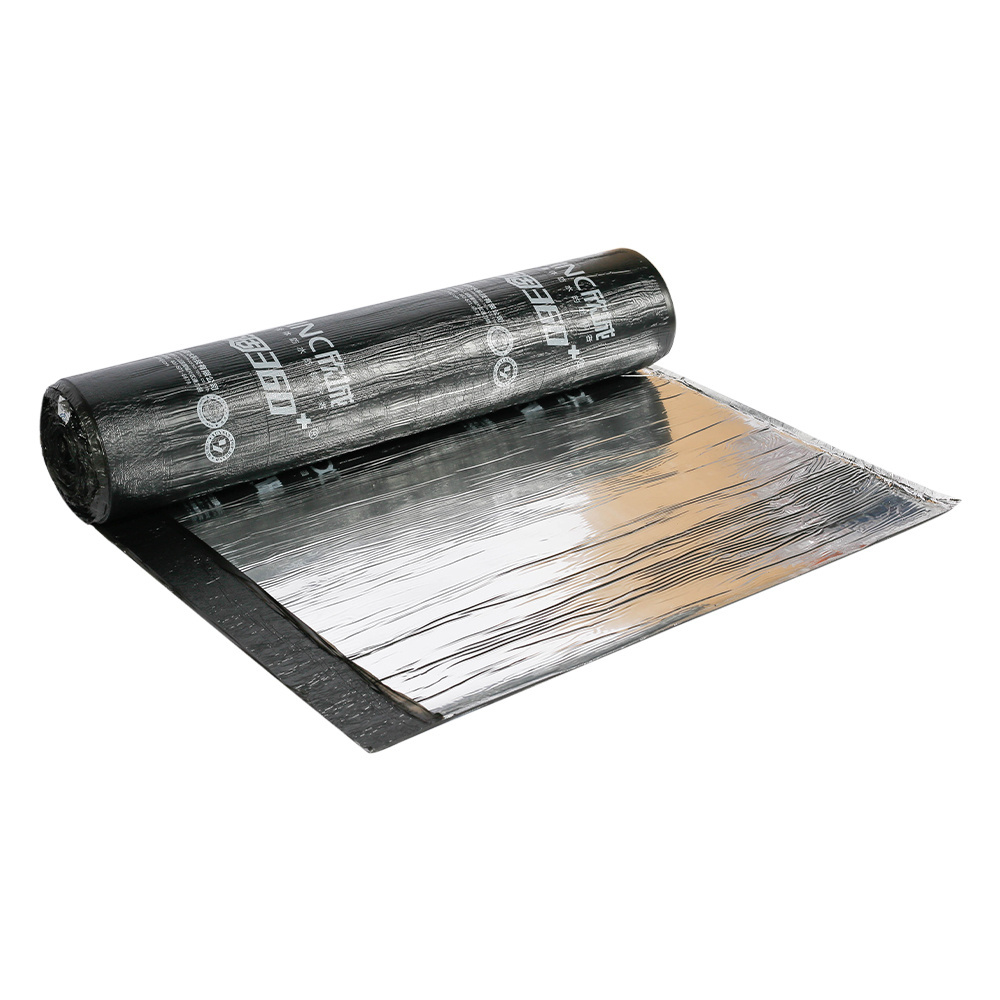

Top surface:

-

Aluminum Film

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support, Return and Replacement

-

Project Solution Capability:

-

total solution for projects, Cross Categories Consolidation

-

Application:

-

Waterproof for Roof

-

Design Style:

-

Traditional

-

Place of Origin:

-

Yunnan, China

-

Brand Name:

-

XINC

-

Model Number:

-

FG360-SBS-AF-1

-

Type:

-

Waterproof Coil

-

Product Name:

-

SBS Modified Bitumen Waterproof Membrane

-

Material:

-

SBS Modified Bitumen

-

Thickness:

-

3.mm

-

Width:

-

1.0m

-

Length:

-

10m

-

Certificate:

-

CE ISO9001

-

Keyword:

-

SBS Waterproof Memebrane

-

Packing:

-

100sqm/roll Wrapped

-

Weight:

-

63kg/roll

-

Top surface:

-

Aluminum Film

Product Details

|

Brief of Introduction of SBS

|

|

|

|

Product Name

|

Elastomer SBS Modified Bitumen Waterproof Membrane Coil with Aluminum Foil

|

|

|

Type Number

|

FG360-SBS-AL-1

|

|

|

Size

|

1m*10m

|

|

|

Packing

|

10 Square Meters per Roll

|

|

|

Weight

|

45kg

|

|

Product Specification

|

Test Item

|

|

|

Unit

|

Technical Index

|

Testing Result

|

Judgement Result

|

||

|

Soluble Content

|

|

|

g/㎡

|

≥2900

|

3252

|

Pass

|

||

|

Heat Resistance

|

90 ℃ Test

Phenomenon

|

|

/

|

No Flow, No Drip

|

No Flow, No Drip

|

Pass

|

||

|

|

90 ℃ Sliding Value

|

Upper Surface

|

mm

|

≤ 2

|

0

|

Pass

|

||

|

|

|

Lower Surface

|

mm

|

≤ 2

|

0

|

|

||

|

Low Temperature Flexibility

|

|

|

/

|

-20℃ No Cracking

|

No Cracking

|

Pass

|

||

|

Imperviousness

|

|

|

/

|

0.3mpa, 30 Min Impermeable

|

Impermeable

|

Pass

|

||

|

Tensile Property

|

Maximum Peak Tension

|

Lengthways

|

N/50mm

|

≥500

|

910

|

Pass

|

||

|

|

|

Crosswise

|

N/50mm

|

≥500

|

890

|

|

||

|

|

Test Phenomenon

|

|

/

|

During the tensile process, the asphalt coating in the middle of the specimen did not crack or separate from the base

|

During The Tensile Process, The Asphalt Coating In The Middle Of The Specimen Did Not Crack Or Separate From The Base

|

|

||

|

Elongation

|

Maximum Elongation Rate

|

Lengthways

|

%

|

≥30

|

55

|

Pass

|

||

|

|

|

Crosswise

|

%

|

≥30

|

60

|

|

||

|

Thermal Ageing

|

Tensile retention

|

Lengthways

|

%

|

≥90

|

104

|

Pass

|

||

|

|

|

Crosswise

|

%

|

≥90

|

113

|

|

||

|

|

Elongation retention rate

|

Lengthways

|

%

|

≥80

|

95

|

|

||

|

|

|

Crosswise

|

%

|

≥80

|

98

|

|

||

|

|

Low Temperature Flexibility

|

|

/

|

-15 ℃ No Cracking

|

No Cracking

|

|

||

|

|

Dimensional Change Rate

|

|

%

|

≤ 0.7

|

0.1

|

|

||

|

|

Mass Loss Rate

|

|

%

|

≤ 1.0

|

0.1

|

|

||

|

Oil Penetration

|

|

|

Sheets

|

≤ 2.0

|

0

|

Pass

|

||

|

Peel Strength at Seam

|

|

|

N/mm

|

≥ 1.5

|

1.7

|

Pass

|

||

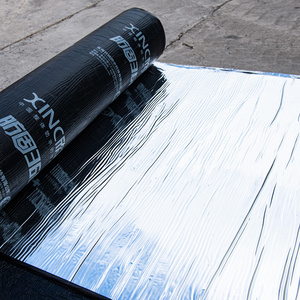

Details Images

Application and Advantage

Remove dust, sand and other debris from the surface of the base to ensure that the surface of the base is clean and dry. For uneven, loose, cracks and other defects, the use of cement mortar repair. For the detailed structures such as Yin and Yang Angle

and through-wall pipes, waterproof treatment should be done.

and through-wall pipes, waterproof treatment should be done.

Place the coil in the desired position and reroll it. Heat gun or blowtorch is used to heat the junction between the bottom surface of the coil and the base to melt the modified asphalt on the bottom edge of the coil. Roll the coil forward while heating, and compact with a press roller to eliminate air, so that the coil and the base bond firmly. Pay attention to adjust the flame

size and moving speed to avoid overheating or insufficient. The vertical and horizontal directions of the lap joints of the coil are 10 cm, and the lap joints must overflow melted modified asphalt glue.

size and moving speed to avoid overheating or insufficient. The vertical and horizontal directions of the lap joints of the coil are 10 cm, and the lap joints must overflow melted modified asphalt glue.

Clean up the construction site, check whether the waterproof layer is smooth, no swelling, no wrinkles, no cracks and other

defects, and deliver it after acceptance.

defects, and deliver it after acceptance.

Recommend Products

In order to achieve the best waterproof properties of the coil, it is recommended to use with our

JS360

+

non-curing waterproof coating.

Packing & Delievery

Hot Searches