Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

LE

-

Brand Name:

-

Langle

-

Product name:

-

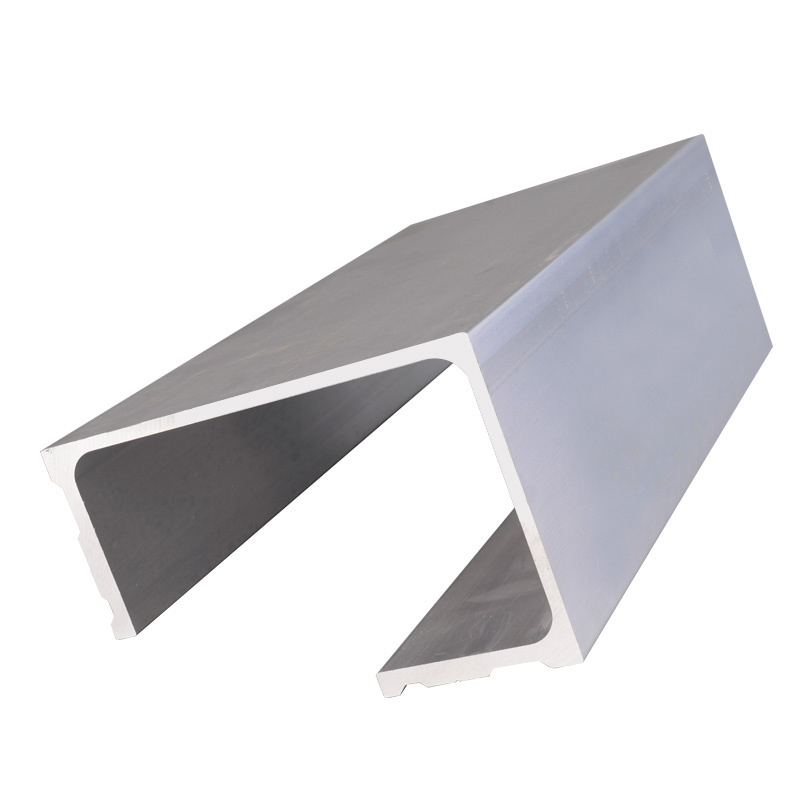

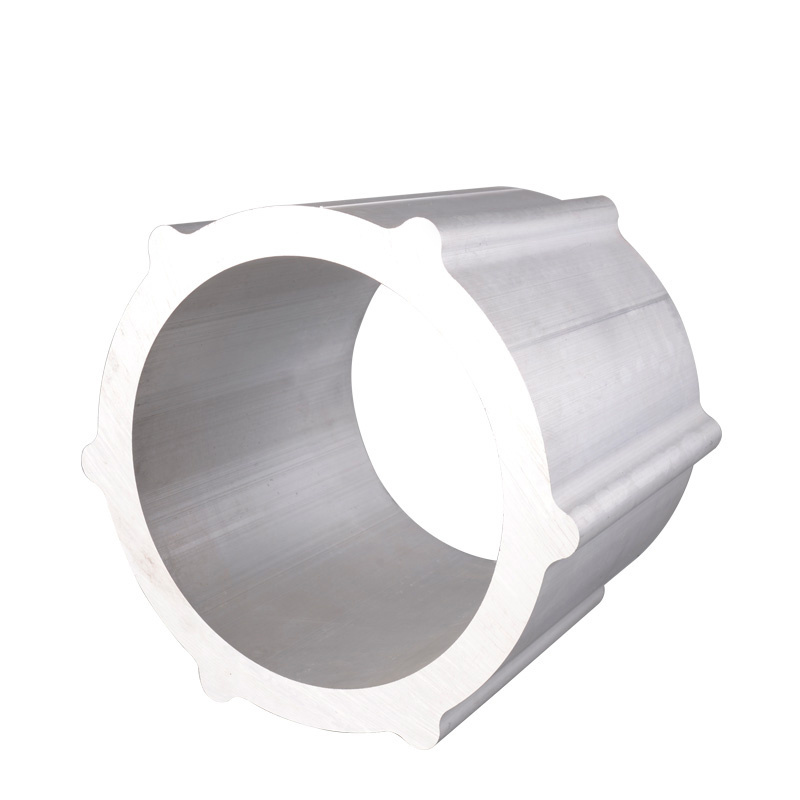

Hannel Profile Slant Bed Lathe Allibaba.com Maching Aluminum Cnc Parts

-

Material:

-

6063 Aluminum Alloy

-

Surface:

-

Anodized

-

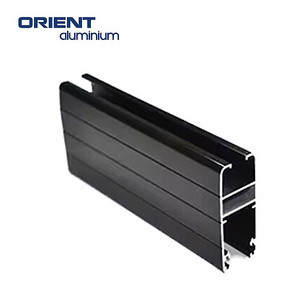

Color:

-

Silver/black

-

Strength:

-

Slim Profile/Durable/Narrow Sightlines/Low Maintenance

-

Length:

-

Customized

-

Usage:

-

6063 Aluminum Extrusion Profile

-

Keyword:

-

Aluminum profile, enclosure

-

MOQ:

-

300KG

Quick Details

-

Grade:

-

6000 Series

-

Tolerance:

-

±5%

-

Place of Origin:

-

Hunan, China

-

Model Number:

-

LE

-

Brand Name:

-

Langle

-

Product name:

-

Hannel Profile Slant Bed Lathe Allibaba.com Maching Aluminum Cnc Parts

-

Material:

-

6063 Aluminum Alloy

-

Surface:

-

Anodized

-

Color:

-

Silver/black

-

Strength:

-

Slim Profile/Durable/Narrow Sightlines/Low Maintenance

-

Length:

-

Customized

-

Usage:

-

6063 Aluminum Extrusion Profile

-

Keyword:

-

Aluminum profile, enclosure

-

MOQ:

-

300KG

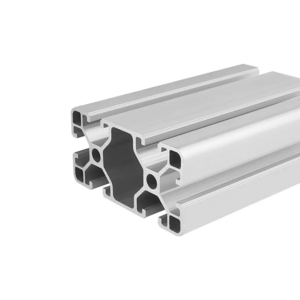

Products Description

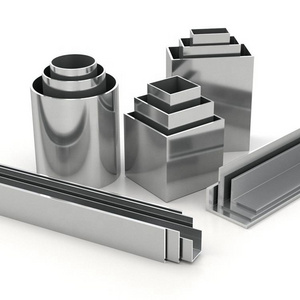

|

item

|

value

|

|

Product Name

|

China wholesale t slot v slot silver black anodized aluminium extrusion profile assembly line frame system types of aluminum profile

|

|

Profile Material

|

6063, 6061 aluminium alloy extrusion profile

|

|

Temper

|

T3, T5, T8

|

|

Surface treatment

|

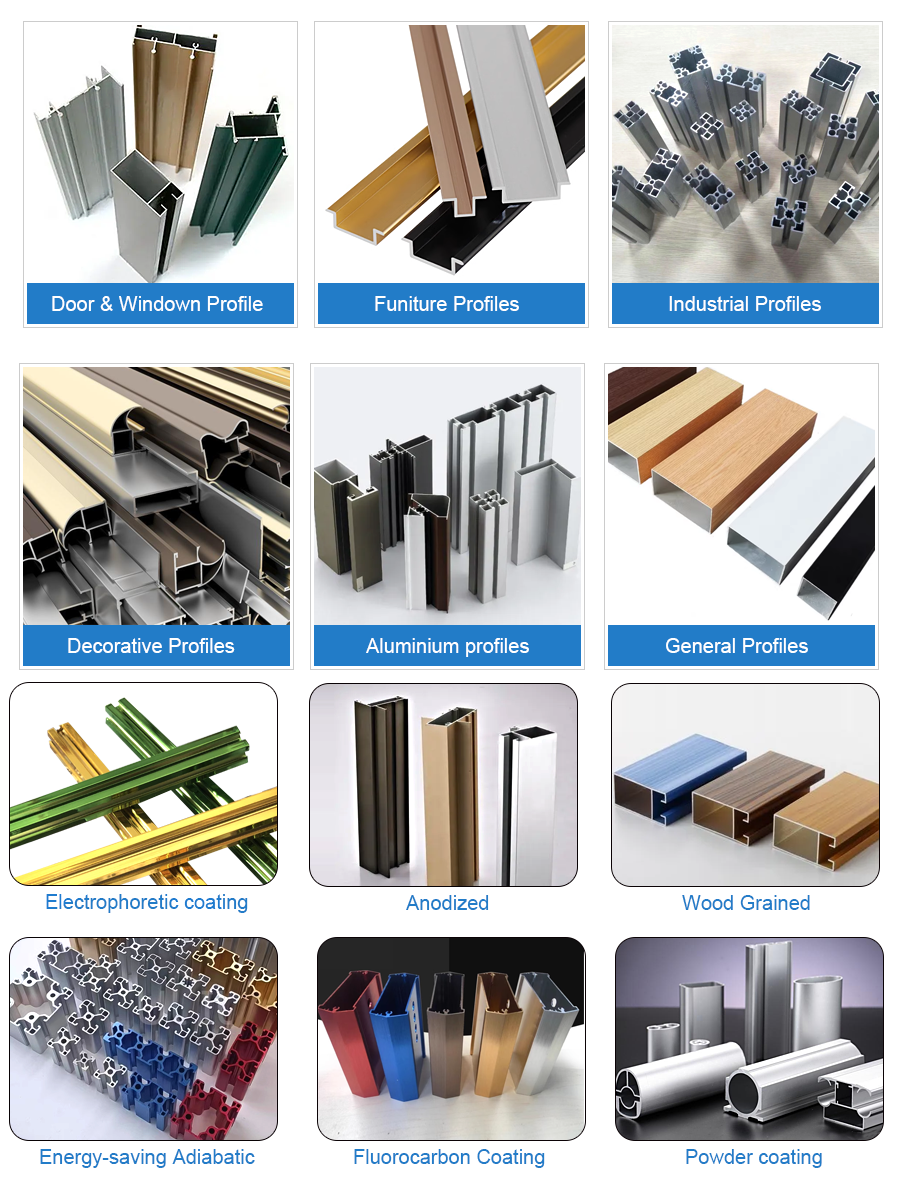

Mill finish, powder coating, anodizing, wooden grain coating, polishing, eletrophoresis, PVDF, sanding blasting, etc.

|

|

The option of Profile

|

15/20/30/40/50/60/80/90/100/120/160/200 series etc.

|

|

Slot width

|

6MM, 8MM, 10MM

|

|

Color

|

Natural silver anodized, black anodized, powder coating grey, can be customised.

|

|

Surface

|

Mill finish, Anodizing, Sand Blasting, Powder coating, etc.

|

|

Deep processing

|

Cutting, Drilling, Treading, Bending, etc.

|

|

Application

|

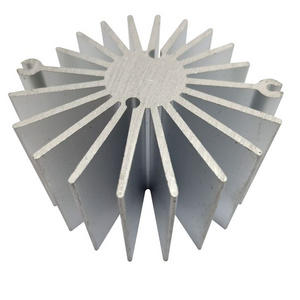

Frame system, Assembly line, Conveyors, Workbench, Machine Guards, Stairs & Platforms, Metal Fence, Display rack, Automotive, Motor aluminium housing, Bridge system, Vessel, Elevator, 3D Printers, CNC Engravers, Non-standard Automation, Hot Wire Machines,

Automation, Laser Cutters, Camera Sliders, Workbench or Worktable, Robotics, Machine frames, Machine guards, etc. |

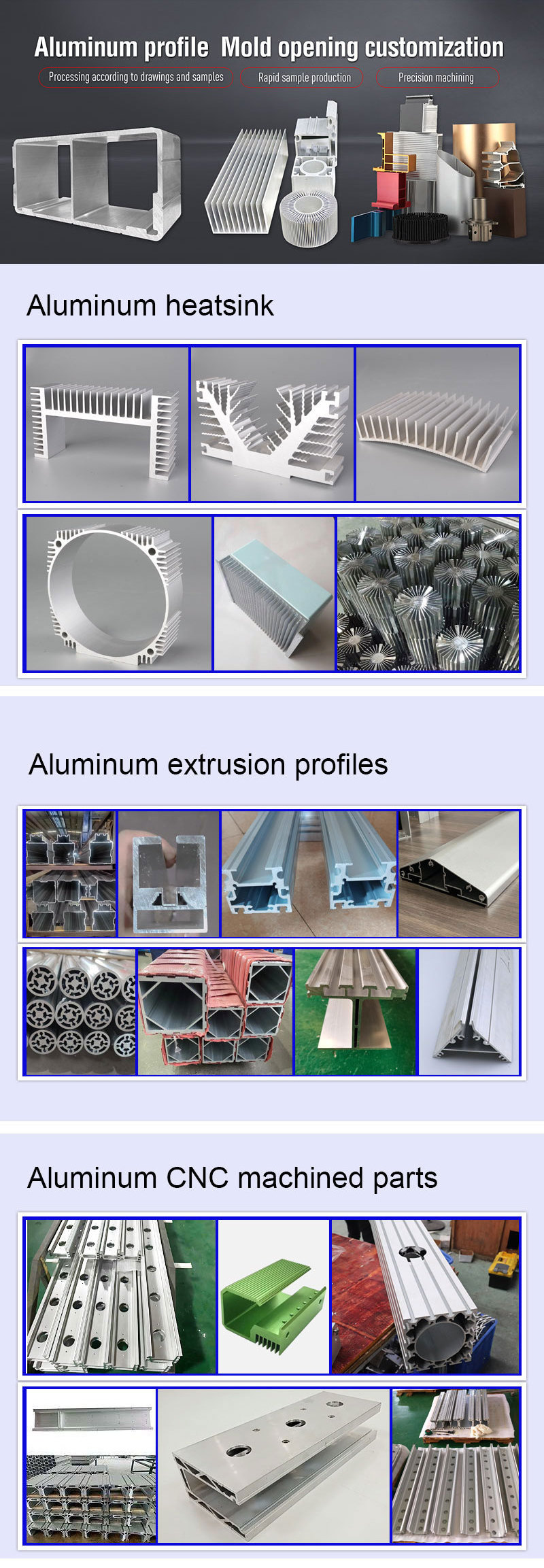

Aluminum Extrusion Process

Aluminum extrusion is an industrial process for forming this metal, most suitable for the production of long aluminum profiles with a constant cross section. This includes unalloyed aluminum and aluminum alloys. Due to the ductility of aluminum, this material is suitable for extrusion, which is why this process is widely used in industry.

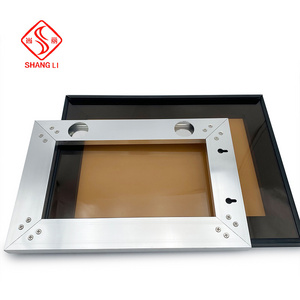

Details Images

Industrial aluminum profiles have a wide range of applications in the manufacturing industry. Here are some examples of their applications:

1. Industrial Equipment and Machinery: Industrial aluminum profiles are used to create structures for various equipment and machinery, such as brackets, bases, covers, and guides, providing stable support and optimized designs.

2. Transportation and Logistics: Industrial aluminum profiles are employed in the manufacturing of shelves, transport vehicles, conveyor belts, and material handling equipment, enhancing transportation efficiency and logistics management.

3. Automation and Robotics: Industrial aluminum profiles play a crucial role in automation systems and robotics, constructing robot structures and motion components.

4. Factories and Production Lines: Industrial aluminum profiles are used in the construction of factory buildings and production line structures, creating efficient production environments and workflows.

5. Power Transmission and Energy: Industrial aluminum profiles are applied in the manufacturing of power transmission lines and energy equipment, providing stable and reliable energy transmission and distribution.

6. Marine Engineering and Construction: Industrial aluminum profiles play a significant role in marine engineering and

construction, used in the manufacturing of ship structures, offshore platforms, and marine facilities.

1. Industrial Equipment and Machinery: Industrial aluminum profiles are used to create structures for various equipment and machinery, such as brackets, bases, covers, and guides, providing stable support and optimized designs.

2. Transportation and Logistics: Industrial aluminum profiles are employed in the manufacturing of shelves, transport vehicles, conveyor belts, and material handling equipment, enhancing transportation efficiency and logistics management.

3. Automation and Robotics: Industrial aluminum profiles play a crucial role in automation systems and robotics, constructing robot structures and motion components.

4. Factories and Production Lines: Industrial aluminum profiles are used in the construction of factory buildings and production line structures, creating efficient production environments and workflows.

5. Power Transmission and Energy: Industrial aluminum profiles are applied in the manufacturing of power transmission lines and energy equipment, providing stable and reliable energy transmission and distribution.

6. Marine Engineering and Construction: Industrial aluminum profiles play a significant role in marine engineering and

construction, used in the manufacturing of ship structures, offshore platforms, and marine facilities.

In summary, industrial aluminum profiles have diverse applications, and their lightweight, corrosion-resistant, and easily

workable characteristics make them the preferred material for industrial manufacturing. They provide reliable and innovative solutions, driving the development and progress of modern industries.

workable characteristics make them the preferred material for industrial manufacturing. They provide reliable and innovative solutions, driving the development and progress of modern industries.

Using Langle aluminum profiles brings many significant advantages. Firstly, Langle aluminum profiles are lightweight, reducing the overall weight of the final product, which lowers transportation and installation costs. Their corrosion resistance ensures long-term use in harsh environments, extending the product's lifespan. Additionally, Langle aluminum profiles are easily processed, allowing for complex shapes and structures to meet diverse project requirements. Moreover, the malleability of aluminum allows Langle profiles to be designed with various appealing aesthetics, enhancing the overall appearance of the project. Notably, Langle aluminum profiles are a sustainable choice, highly recyclable, and meet environmental standards, contributing to eco-friendly projects. In conclusion, choosing Langle aluminum profiles means opting for exceptional materials that provide high-quality, innovative, efficient, and reliable solutions, catering to the diverse needs of various industries.

Customer's Reviews

Company Introduction

Hot Searches