- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Henan, China, Henan China

-

Brand Name:

-

mingxin

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

1360x1350x1600mm

-

Weight (KG):

-

800 kg

-

Product Name:

-

brick making machine

-

Installation:

-

Engineer Guide

-

Application:

-

Coal gangue,Shale

-

Brand:

-

Henan mingxin

-

Keyword:

-

Clay brick

-

After-sales Service:

-

Supporting Inquiry and consult

-

Color:

-

White ,Green, designated color is available

Quick Details

-

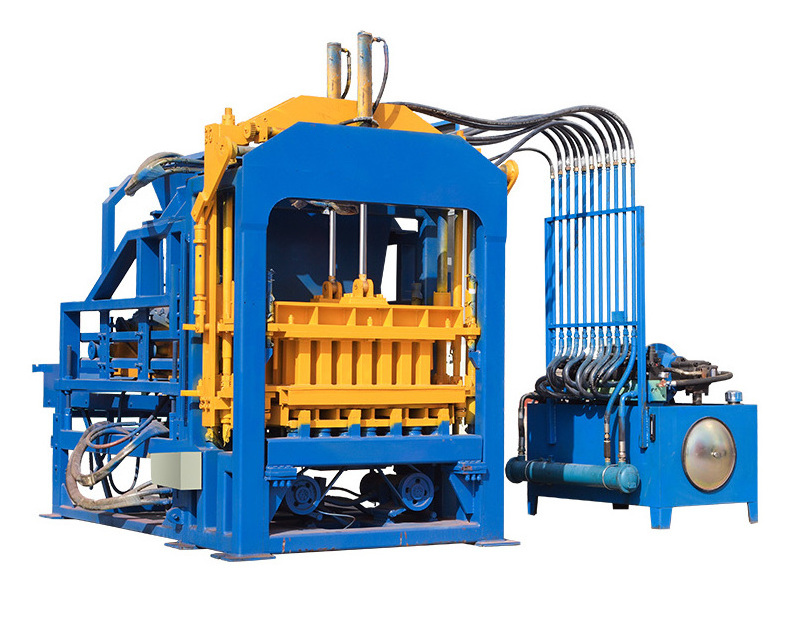

Type:

-

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine

-

Brick Raw Material:

-

Cement

-

Production Capacity (Pieces/8 hours):

-

4480 pcs/8hours, 2500 pcs/8hours, 3400 pcs/8hours, 1920 pcs/8hours, 5760 pcs/8hours, 1500 pcs/8hours, 1280 pcs/8hours, 3000 pcs/8hours, 12000 pcs/8hours, 3200 pcs/8hours, 2560 pcs/8hours, 1000 pcs/8hours, 800 pcs/8hours, 657pcs./hour

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm

-

Place of Origin:

-

Henan, China, Henan China

-

Brand Name:

-

mingxin

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

1360x1350x1600mm

-

Weight (KG):

-

800 kg

-

Product Name:

-

brick making machine

-

Installation:

-

Engineer Guide

-

Application:

-

Coal gangue,Shale

-

Brand:

-

Henan mingxin

-

Keyword:

-

Clay brick

-

After-sales Service:

-

Supporting Inquiry and consult

-

Color:

-

White ,Green, designated color is available

laterite foam brick machine clay

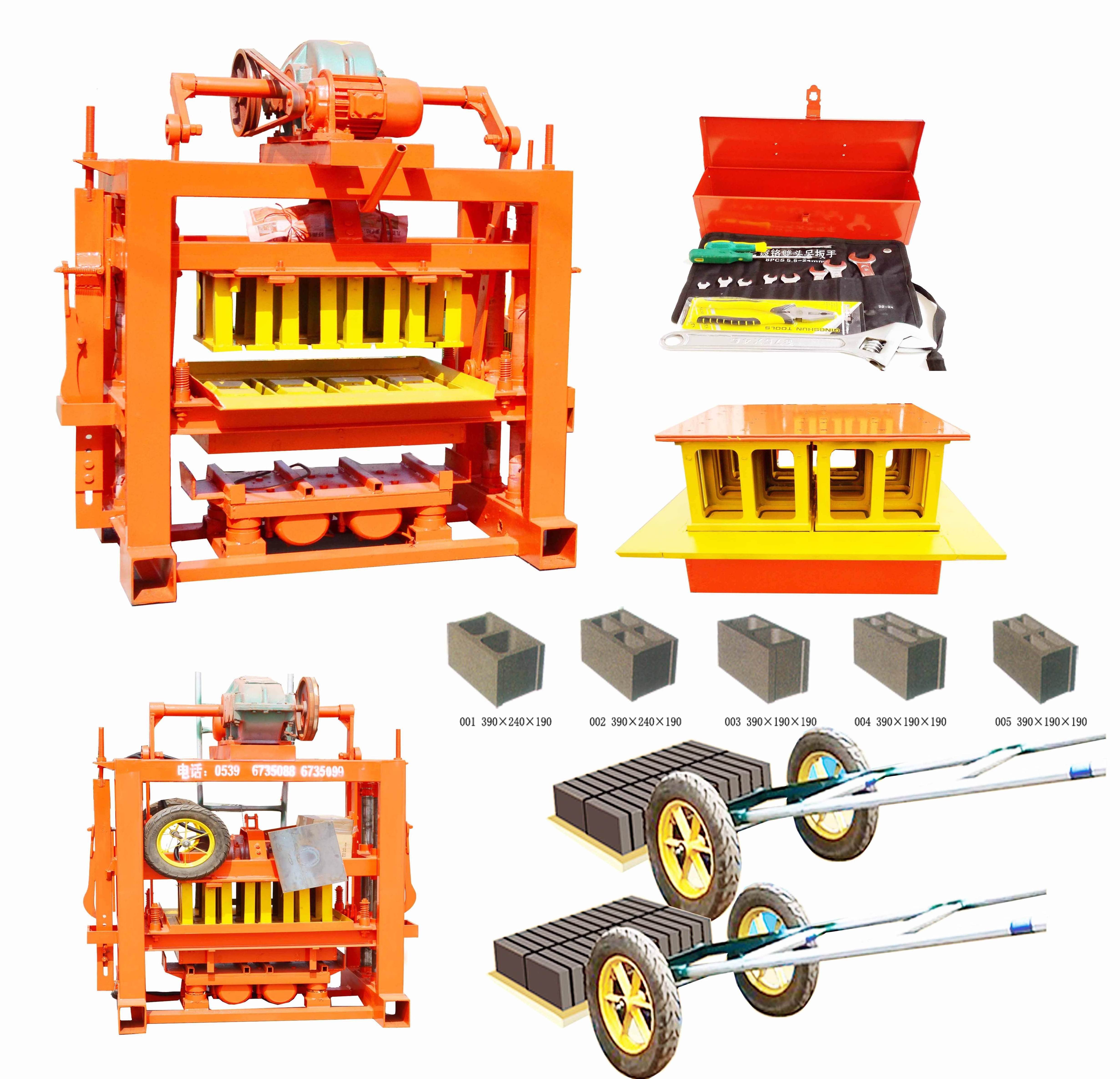

The machine is a small block production equipment, easy to operate, can produce hollow block, porous block, solid concrete brick, etc. There is a vibrator on the upper mold and two vibrators on the lower mold. The exciting force in three different directions makes the block quality good. This kind of manual block making machine uses spring to cushion and pressurize, which reduces wear. The product has the advantages of fast forming, high density and high pressure. After demoulding, these blocks can bear the weight of one person.

Working principle of laterite foam brick machine clay

This machine is manufactured on the base of technical modification to the original block shaping machines,that is changing the former one -time-vibration into twice-vibration of moulding core.so ,the block density becomes higher,shaping speed quicker and block strenght more even, this model of machine can be suitable to the customers who have any kinds of existing cement working sites, and the consumption pallests can be reduced.

Characteristics of laterite foam brick machine clay

1, The manual mud brick machine has the advantages of simple structure, compactness, convenient operation, convenient maintenance, small hardness, high output, less investment and quick effect.

2, The raw materials are abundant and can be seen everywhere. It is very convenient to invest and build factories.

3, Fast product forming, high density and high pressure.

Mould of building brick machine manual india

Block Samples by laterite foam brick machine clay

Capacity of laterite foam brick machine clay

| product | brick size | PCS./Pallet | PCS./YEAR |

| hollow brick | 390*190*190mm | 6 | 5760000 |

| Floor tile |

200*100*60mm |

21 | 365000 square |

| Standard brick | 240*115*53mm | 30 | 34560000 |

| Perforated brick | 240*115*90mm | 15 | 17280000 |

RAW MATERIAL: Steel slag, river sand, chemical slag, fly ash, construction waste, coal powder, gangue, slag, steel slag, mineral sand, gravel, carbon slag, ceramsite shale water slag...

Our brick machine can adopt the following raw materials to make the good quality hollow brick, solid brick and paver brick.

1.Cement: 10%~20%;

2.Sand: 30~40%;

3.Crushed Stone (<5cm): 30~40%;

Finished product drawing

Packaging Details : The normal packing is wooden case (size: length * width * height). We will use plastic film for inner packaging or according to the special requirements of customers.

1. 24 hours all day service

2. Can be customized according to customer needs .

3. C heck again before we send the goods .

4. S end the goods on time .

5.One year warranty from the date of receiving.

6 . We can test the machine before we send it if the client need .

7 . The more you need, the cheaper the unit price is