- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Stainless Steel

-

Type:

-

tank parts

-

Usage:

-

pressure/no pressure tank

-

Processing Types:

-

food , beer , beverage , dairy

-

Dimensions:

-

350-600mm, DN300-DN800

-

Package:

-

standard package

-

Connection:

-

Welded,clamped,threaded (union)ends

-

Product name:

-

manway covers

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

QR

-

Model Number:

-

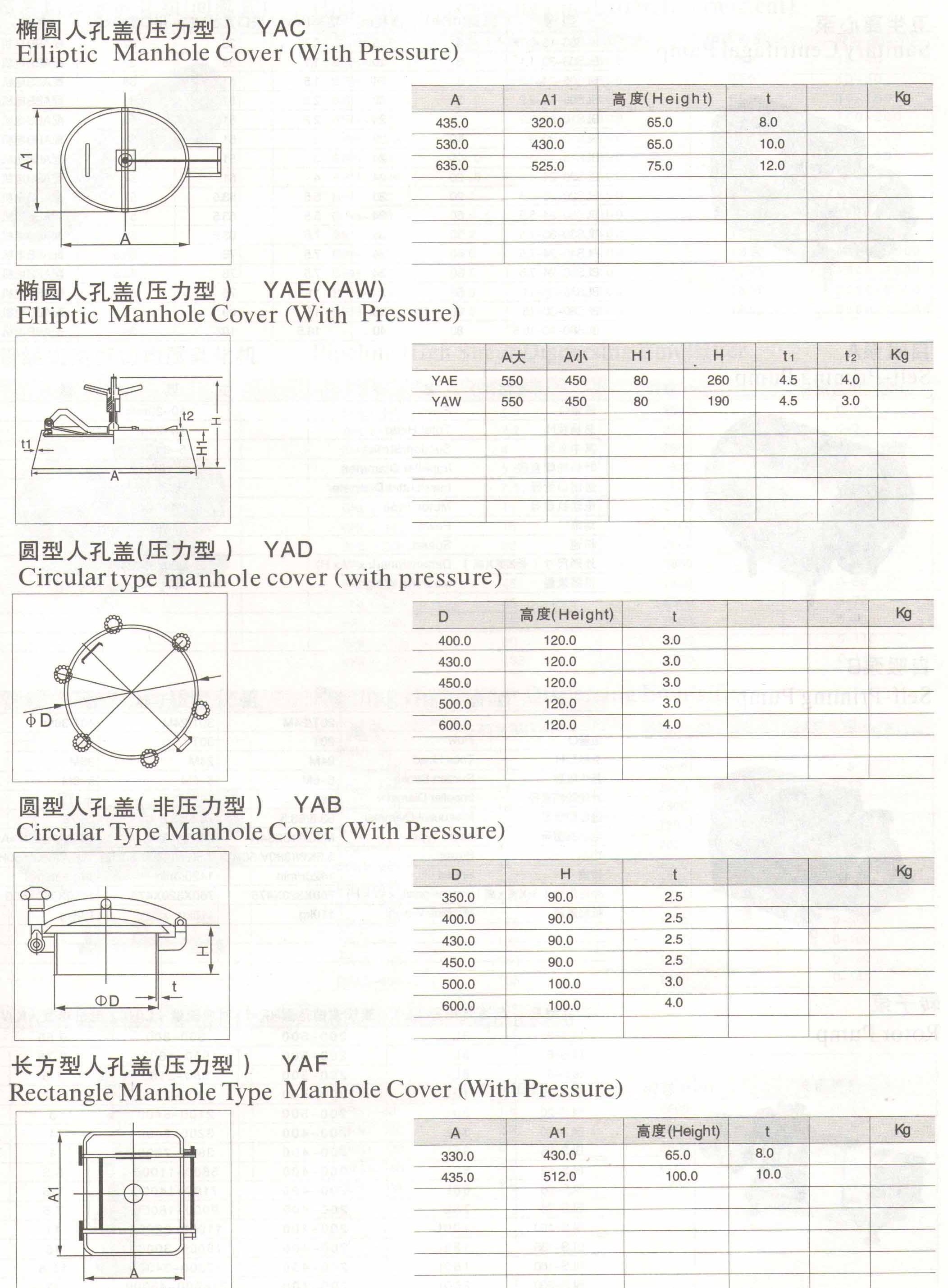

YAA,YAB,YAC,YAD,YAE,YAF, YAB/YAC/YAD/YAE/YAF

-

Material:

-

Stainless Steel

-

Type:

-

tank parts

-

Usage:

-

pressure/no pressure tank

-

Processing Types:

-

food , beer , beverage , dairy

-

Dimensions:

-

350-600mm, DN300-DN800

-

Package:

-

standard package

-

Connection:

-

Welded,clamped,threaded (union)ends

-

Product name:

-

manway covers

Video Description

Product Description

|

Product Description:

1).Product Name: Oval inward manway cover with bevel edge 2).Material: SS304 or SS316L 3). Size: 8"-24" (200mm-600mm) 4).Height: 100mm 120mm 5).Thickness: 1.5-3mm 6).Handle Material : Stainless steel and plastic 7).Type: With sight glass or without. 8). Seal Material: Silicone, EPDM, Viton, NBR 9). Surface Finishing: Ra≤0.8 10).Working Temperature: -10 degree to +120 degree (EPDM) 11).Working Pressure: 1-3 Bar |

Jacket liquid mixing tank, it's widely applied in the beverage, food, dairy, pharmaceutical, chemical and process industries used

as blending tank, buffer tank, melting tank, high shear mixing tank and emulsifying tank, which cleanable to sanitary standards . Product Features: 1) Material: SUS304/ SUS 316L 2) Layer: Single layer/ double layers/ three layers 3) Power: 0.55~55KW 4) Capacity: 50L~50,000L 5) Voltage: 110V~680V, can be customized 6) Heating Type: electric/ steam heating 7) Polish: mirror polish inside and outside |

|

|

Factory Scale

:

1) Located in: Zhejiang, China 2) Factory Area: 5000SQ.M 3) Employees: 37 4) Production Ability: 100 Pieces/Stainless cteel SS316l round manway cover |

Advantages:

1) Certificates: 3A, SMS, DIN, RJT, IDF 2) Warranty: 12 months 3) OEM/ODM: can design, exploitation and manufacture by CAD software and drawing. 4) Testing&QC: pressure test and material test |

|

|

Production Line:

1) Engineers: 3 2) Workers: 20 3) Welding: 4 4) Polishing: 3 5) Testing: 2 6) Packing: 2 |

Delivery Time:

1) Material Preparation Time: 2 days 2) Metal Processing Time: 7-10 days, based on actrual quantity 3) Test & Packaging Time: 1 day |

|

How To Choose:

Description:

It is applied in

large stainless steel tanks

and vessels, for such application requires the pathways to the inner parts of the

tanks

or vessels could be locked up Widely used in

food, beverage, pharmaceutical, bioengineering, water treatment, daily chemical, petroleum and chemical industries.

Manhole making process:

Recommend Products

Hot Searches