- Product Details

- {{item.text}}

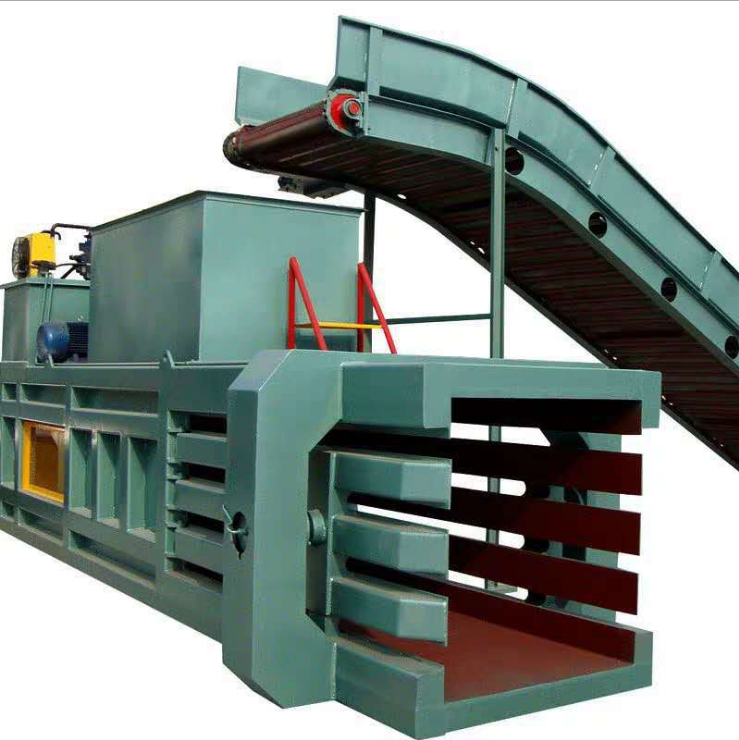

Quick Details

-

Brand Name:

-

ENWEI

-

Weight:

-

12000 KG

-

Dimension(L*W*H):

-

7000*1700*1900mm

-

Keywords:

-

horizontal baler

-

Packed size (cm):

-

1600*1100*800mm

-

Pressure:

-

140 Ton

Quick Details

-

Voltage:

-

380

-

Power:

-

18.5kw; 22kw; 45kw*2

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ENWEI

-

Weight:

-

12000 KG

-

Dimension(L*W*H):

-

7000*1700*1900mm

-

Keywords:

-

horizontal baler

-

Packed size (cm):

-

1600*1100*800mm

-

Pressure:

-

140 Ton

Products Description

Hydraulic baler is suitable for straw, forage, waste paper packing, cotton packing, garment packing, straw packing, plastic packing, wool packing, recyclable garbage packing, cotton, wool, waste paper box, waste paperboard , yarn, tobacco, plastic,cloth, woven bags, knitted cashmere, hemp, sacks, tops, hair balls, silk, silk, hops, waste plastic bags, and other soft materials such as light foam, loose materials, etc. Compact, tidy and aesthetically pleasing, significantly reducing transportation costs.

About Horizontal Hydraulic Baling Press Machine Horizontal hydraulic baling press machine: 80 Ton, 100 Ton, 125 Ton, 140 Ton, 160 Ton, 180 Ton Vertical hydraulic baling press machine: 10 Tons single cylinder, 20 Tons single cylinder, 30 Tons single cylinder, 30 Tons double cylinder, 40 Tons double cylinder, 60 Tons double cylinder (Automatic push bag), 80 Tons double cylinder (Automatic push bag), 100 Tons double cylinder (Automatic push bag). The size of machine can be processed and produced according to customer requirements.

Main advantages

1. According domestic and foreign advanced baler production design and quality technology standards for production.

2. Reliable quality, stable performance, high safety; widely used, stylish appearance, fine workmanship.

3. Seven strapping trough design, easy to operate, automatic roll-over, saving effort and worry;

4. Optional anti-rebound anti-knife device, equipped with safety emergency stop switch.

5. Low noise, high efficiency, non-pressure stroke work, automatic pressure return.

6. It has the functions of overflow and preventing system overload, and its performance is reliable.

7. Equipped with a pressure switch, the system will automatically stop after reaching a certain pressure to avoid human and motorized design damage.

8. The size and block can be customized according to customer requirements. The feeding port is enlarged and widened to make filling easier and faster. The machine is processed and produced in accordance with international standards and equipped with high-speed motors. The company has a one-stop production line with advanced technology.

9. High temperature weather can ensure the low temperature production of hydraulic oil and reduce the harm to machinery and equipment. Before you place an order, please contact us to calculate the freight. Our machines have 1 year warranty.

Main advantages

1. According domestic and foreign advanced baler production design and quality technology standards for production.

2. Reliable quality, stable performance, high safety; widely used, stylish appearance, fine workmanship.

3. Seven strapping trough design, easy to operate, automatic roll-over, saving effort and worry;

4. Optional anti-rebound anti-knife device, equipped with safety emergency stop switch.

5. Low noise, high efficiency, non-pressure stroke work, automatic pressure return.

6. It has the functions of overflow and preventing system overload, and its performance is reliable.

7. Equipped with a pressure switch, the system will automatically stop after reaching a certain pressure to avoid human and motorized design damage.

8. The size and block can be customized according to customer requirements. The feeding port is enlarged and widened to make filling easier and faster. The machine is processed and produced in accordance with international standards and equipped with high-speed motors. The company has a one-stop production line with advanced technology.

9. High temperature weather can ensure the low temperature production of hydraulic oil and reduce the harm to machinery and equipment. Before you place an order, please contact us to calculate the freight. Our machines have 1 year warranty.

Product Parameters

|

Product model

|

Power (kw)

|

Packing size (mm)

|

Overall dimensions (mm)

|

Oil pump

|

Cylinder outer diameter (cm)

|

|

60T with side door

|

18.5

|

1200*700*600

|

4800*1200*1700

|

80type

|

18.5

|

|

60T without door

|

18.5

|

1800(adjustment)*600*700

|

5200*1200*1700

|

80type

|

18.5

|

|

100T with side door

|

22

|

1600*1100*800

|

6800*1700*1900

|

80type

|

18.5

|

|

100T lift door

|

22

|

1600*1100*800

|

6800*1700*1900

|

80type

|

18.5

|

|

100T without door

|

22

|

1600(adjustment)*1100*800

|

7300*2200*1900

|

80type

|

18.5

|

|

120T with side door

|

22

|

1600*1100*800

|

6800*1700*1900

|

80type

|

23

|

|

120T lift door

|

22

|

1600*1100*800

|

7300*2200*1800

|

80type

|

23

|

|

120T without door

|

22

|

1600(adjustment)*1100*800

|

7300*2200*1900

|

80type

|

23

|

|

140T with side door

|

22

|

1600*1100*800

|

7000*1700*1900

|

125type

|

25

|

|

140T lift door

|

22

|

1600*1100*800

|

7000*1700*1900

|

125type

|

25

|

|

140T without door

|

22

|

1600(adjustment)*1100*800

|

7500*2300*1900

|

125type

|

25

|

|

150T with side door

|

30

|

1800*1100*850

|

8600*1600*1900

|

125type

|

25

|

|

160T with side door

|

37

|

1800*1100*1250

|

9600*2300*3600

|

Double oil pump

|

30

|

|

160T without door

|

37

|

3000(adjustment)*1100*1250

|

9600*2300*3600

|

Double oil pump

|

30

|

|

200T without door

|

37

|

1800(adjustment)*1100*1250

|

10800*2300*3600

|

Double oil pump

|

35

|

Details Images

Dual control box

It is easy to operate and can be operated remotely. You can choose the control mode according to your own habits.

Oil level thermometer

The oil level thermometer is installed on the oil tank of each horizontal machine, which can pay attention to the oil level and temperature in real time to adjust the operation of the machine.

Upgrade the outlet of rail steel

The steel material at the side of ladle outlet is upgraded from channel steel to rail steel, which is more firm. Ensure that the compression path of trolley (pressure plate) will not deviate.

Four layer steel wire high pressure oil pipe

Four layer steel wire high pressure oil pipe is used, which is wear-resistant, high density and thick wall pipe. Ensure no oil injection and oil leakage during operation.

High quality copper core motor

Each machine is equipped with high-quality double full copper coil motor to ensure the stable operation of the machine and the smooth preparation of the package after compression. The large motor controls the main board pressure, and the small motor controls the door opening and closing.

Brand high pressure plunger pump

JINDA high pressure plunger pump, high efficiency, low noise, high quality. The flow passage from the inlet to the outlet of the pump is made of cast iron, and the pump body is non corrosive and anti-wear hydraulic oil-based medium

Installation of large diameter butterfly valve

Each machine is equipped with large diameter butterfly valve. The oil inlet pipeline is thick and the oil inlet is smooth. There will be no shortage of oil supply during the re compression.

Side door hydraulic cylinder

From the former double end plug-in type to the fixed type hydraulic cylinder, the movable performance is large and wide, more stable than before, the oil cylinder is increased, the strength is sufficient, and the unlocking and locking is more convenient.

Company Certifications

Factory Show

Contact:

Mobile/wechat:+86-18660767011

Whatsapp:+86-15066371715

Hot Searches