- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Yincai sci & tech

-

Model Number:

-

Glass ink_Single component

-

Certificate:

-

MSDS

-

Application:

-

Direct glass print

-

Ink Type:

-

Sovent based Ink

-

Drying:

-

Nature drying

Quick Details

-

Type:

-

Solvent Ink

-

Printing Type:

-

Screen printing

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Yincai sci & tech

-

Model Number:

-

Glass ink_Single component

-

Certificate:

-

MSDS

-

Application:

-

Direct glass print

-

Ink Type:

-

Sovent based Ink

-

Drying:

-

Nature drying

|

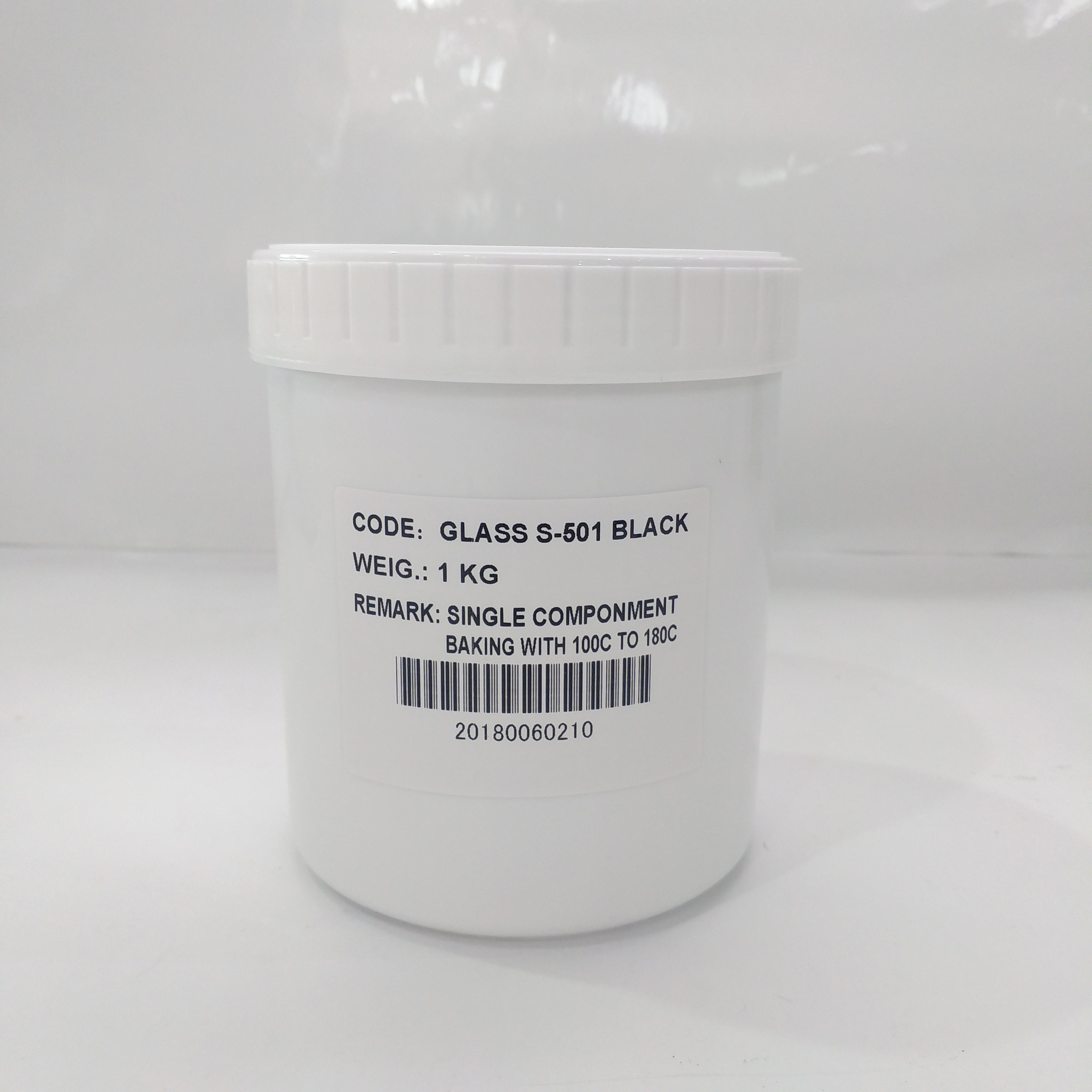

ITEM

|

Glass ink_Single component

|

|

|

|

|||

|

CODE

|

SC series

|

|

|

|

|||

|

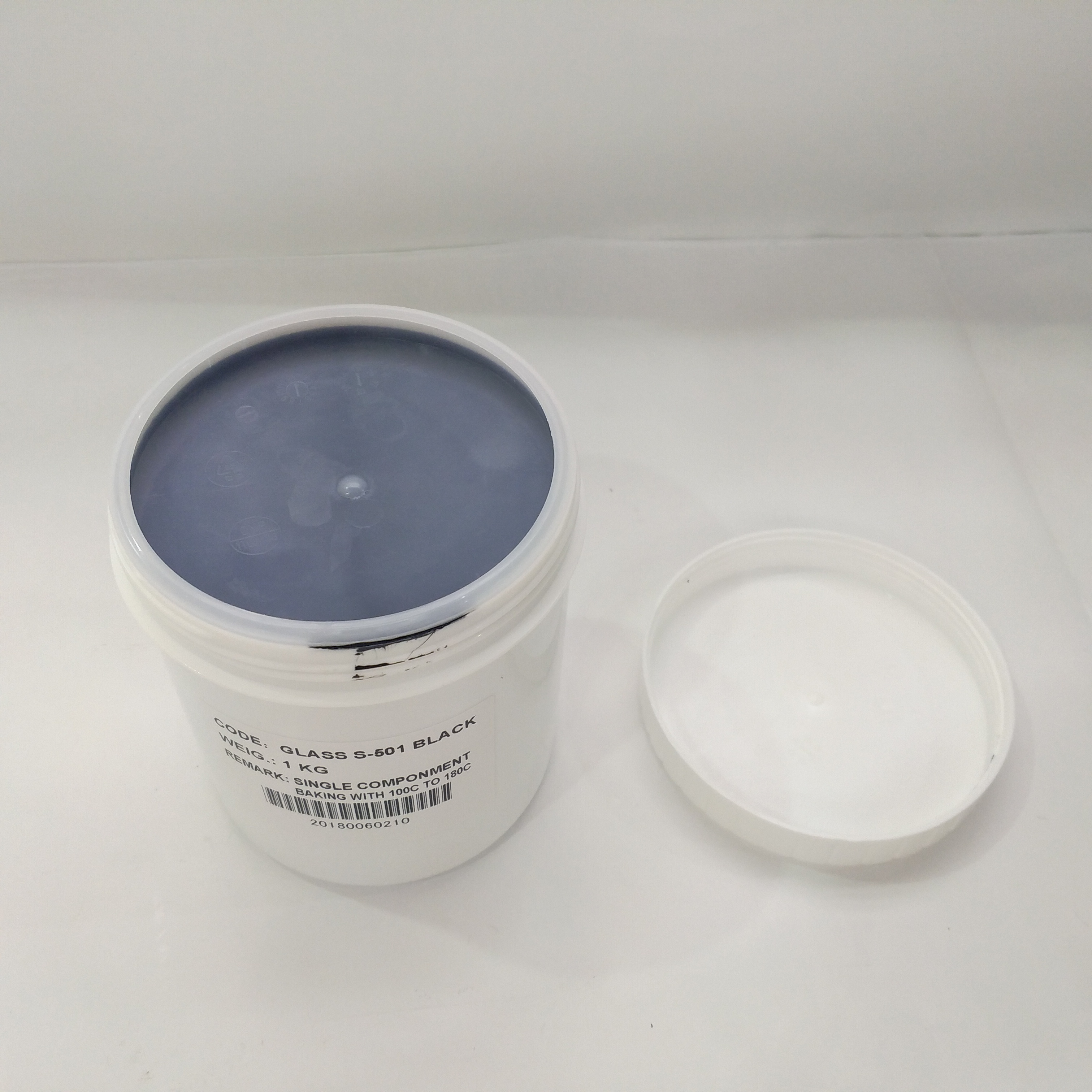

CAPACITY

|

1kg/can

|

|

|

|

|||

|

G/WEIGHT

|

1.2kg

|

|

|

|

|||

|

GLOSSINESS

|

Glossy

|

|

|

|

|||

|

REDUCER & RATE

|

YC-02/3%-8%

|

|

|

|

|||

|

HARDENER

|

NO

|

|

|

|

|||

|

Drying time

|

Oven by 120C to 180C, 10min to 25 min

|

|

|

|

|||

|

STOREAGE

|

Sealed and dry place

|

|

|

|

|||

|

PRINTING CAPACITY

|

(300mesh) 30sqm/kg

|

|

|

|

|||

2.Printing with 200meshes, oven by 130°C~150°C for 10~15 min.We have the service as toner for printing ink of crystal glass of refrigerator, air-condition, cooker hood.

3.Environmental

Standard of Europe EN-71PART3

Standard of Japan STMA-RT3

Standard of American ASTM-F963-96A

4.It is a double components ink add hardener additional. Excellent adhesion after heat dry, even have srong ahesion on some coated hard adhere.

5.The mixture is wear-resistance, alcohol resistance and solvent resistance. Workable the metal and glass nameplate, especial widely for the glass accessories as well.

6.The printed glass dry by wing also have good ahesion but poor on chemical resistance than heat dry.

7.Smooth, scuff resistance, glossy.

Mixed hardener with 5%

The ink with hardener must use up in 8 hours. If could not finish, need to re-mixed hardener with same rate.

Do not mix new ink with used one

Mixed thiner/diluent with 8% to 10%

Stard to print

Drying time

It need to put on the drying rack and a no-dust room.

Testing

2005, Yincai first place office, we star in a 100sqm office room, only 5 people, we work hard, we like a family.

From there, Yincai has been star to export trading, not much, but we have tend to be the expert on this filed

2008, We have own equipment factory "HongJi" sell to domastic and export.

"HongJi" have 50 peoples, 3000sqm, mainly manufacture pre-press equipmemt and screen printing machine.

2011, Yincai move to a large office with 2 floor bcz we have 10 people already.

See, smell is my boss icon.

The first decade

2014, The first decade, Yincai have own building in a industry part. We are gethering with reserch, develop, product, sale and after sales company.

2010 DongGuan Printing fair

2009 Guangzhou equipment fair

2008 Shenzhen Printing supplies fair

2011 Shanghai screen printing equipment fair

2012 year shanghai fair

2018 Jiangsu fair

Regular learning new products & feedback customer question

Anniversary Celebration