- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Application:

-

chemical processing industry

-

Grade:

-

nickel alloy 200

-

Ni (Min):

-

99.2

-

Model Number:

-

nickel alloy 200

-

Brand Name:

-

Shanghai yikai

-

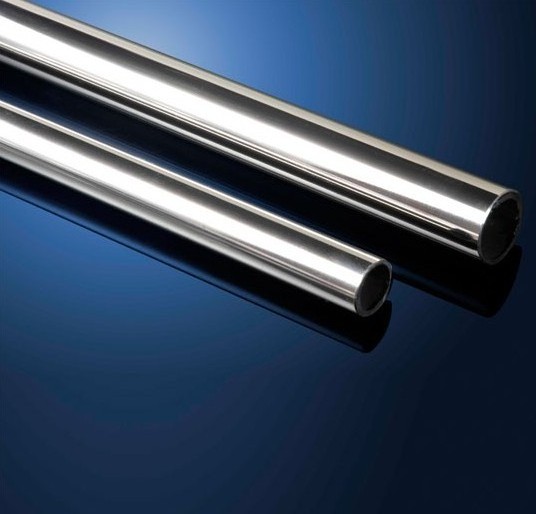

Name:

-

nickel alloy 200 bar

-

Process method:

-

Plasma cutting (±1/32")

-

Cutting process:

-

Oxyacetylene cutting (±1/16")

-

No.1:

-

Laser cutting (±0.002")

-

No.2:

-

Water Jet (±0.005")

-

No.3:

-

Welding

Quick Details

-

Powder Or Not:

-

Not Powder

-

Ultimate Strength (≥ MPa):

-

60-85

-

Elongation (≥ %):

-

55-35

-

Place of Origin:

-

Jiangsu, China

-

Application:

-

chemical processing industry

-

Grade:

-

nickel alloy 200

-

Ni (Min):

-

99.2

-

Model Number:

-

nickel alloy 200

-

Brand Name:

-

Shanghai yikai

-

Name:

-

nickel alloy 200 bar

-

Process method:

-

Plasma cutting (±1/32")

-

Cutting process:

-

Oxyacetylene cutting (±1/16")

-

No.1:

-

Laser cutting (±0.002")

-

No.2:

-

Water Jet (±0.005")

-

No.3:

-

Welding

Nickel 200/201

UNS Number N02200/N02201

Nickel 200 and Nickel 201 are solid solution strengthened, commercially pure wrought materials with good mechanical properties over a wide range of temperatures and excellent resistance to many corrosives, in particular hydroxides. Nickel 201 was a modification of 200 to control carbon (.02 max) which keeps it from being embrittled by intergranular precipitates at temperatures of 600° F to 1400° F in many processes. Typically, the elemental restrictions of both, nickel 200 and nickel 201, are combined into one, dual-certified chemistry resulting in a single alloy with the desired characteristics of both alloys, Nickel 200/201.

-

Nickel 200/201 ASTM Specifications

Pipe Smls Pipe Welded Tube Smls Tube Welded Sheet/Plate Bar Fitting B161 B622 B161 B622 B162 B160 B163 Mechanical Properties

Room Temperature properties of Various ProductsProduct Form Condition Tensile (ksi) .2% Yield (ksi) Elongation (%) Hardness (HRB) Rod & Bar Hot Finished 60-85 15-45 55-35 45-80 Rod & Bar Cold Drawn/Annealed or Hot-Finished/Annealed 55-75 15-30 55-40 45-70 Plate Hot-Rolled/Annealed 55-80 15-40 60-40 45-75 Sheet Annealed 55-75 15-30 55-40 70 max Tube & Pipe Seamless Annealed 55-75 12-30 60-40 70 max

Application field

· Architectural/Civil Engineering : Cladding, handrails, door and window fittings, street furniture, structural sections, enforcement bar, lighting columns, lintels, masonry supports.

· Transport : Exhaust systems, car trim/grilles, road tankers, ship containers, ships chemical tankers, refuse vehicles.

· Chemical/Pharmaceutical : Pressure vessels, process piping.

· Oil and gas : Platform accommodation, cable trays, sub-sea pipelines.

· Medical : Surgical instruments, surgical implants, food processing.

· Food and Drink : Catering equipment, brewing, distilling, food processing.

· Water : Water and sewage treatment, water tubing, hot water tanks.

· General : Springs, fasteners(bolts, nuts and washers) wire.

FAQ

1. If we travel to China to checking your facility, are you welcome?

Of course, why not?

we will provide the whole accompany from you landing in China.

Only Give us a call before your arrive.

We will pick up you from the airport, living in our company's hotel, and driving by car take you visiting our company.

Warm Welcome!

2. How many sales person in your team?

present 5 sales, but more hands help in work, total team is 20+ workers.

So do not worry, not the one person company.

3. How Many Years of your company working in this industry?

We are 20+ years, from last century.

Expanding the market, and cultivate our techniques, two ways all in work together.

4. Could you show me some photos of your producing working?

here, following is our working plant, all is same when you come to China to audit.