- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

-

-

CrO Content (%):

-

-

-

SiC Content (%):

-

-

-

Place of Origin:

-

Henan, China

-

Model Number:

-

-

-

Brand Name:

-

RS

-

Product name:

-

magnesia zircon refractory brick

-

MgO Content:

-

<0.7%

-

Refractoriness (Degree)::

-

Common (1580°< Refractoriness< 1770°)

Quick Details

-

SiO2 Content (%):

-

-

-

Al2O3 Content (%):

-

--, >58%

-

MgO Content (%):

-

-

-

CaO Content (%):

-

-

-

CrO Content (%):

-

-

-

SiC Content (%):

-

-

-

Place of Origin:

-

Henan, China

-

Model Number:

-

-

-

Brand Name:

-

RS

-

Product name:

-

magnesia zircon refractory brick

-

MgO Content:

-

<0.7%

-

Refractoriness (Degree)::

-

Common (1580°< Refractoriness< 1770°)

Products Description

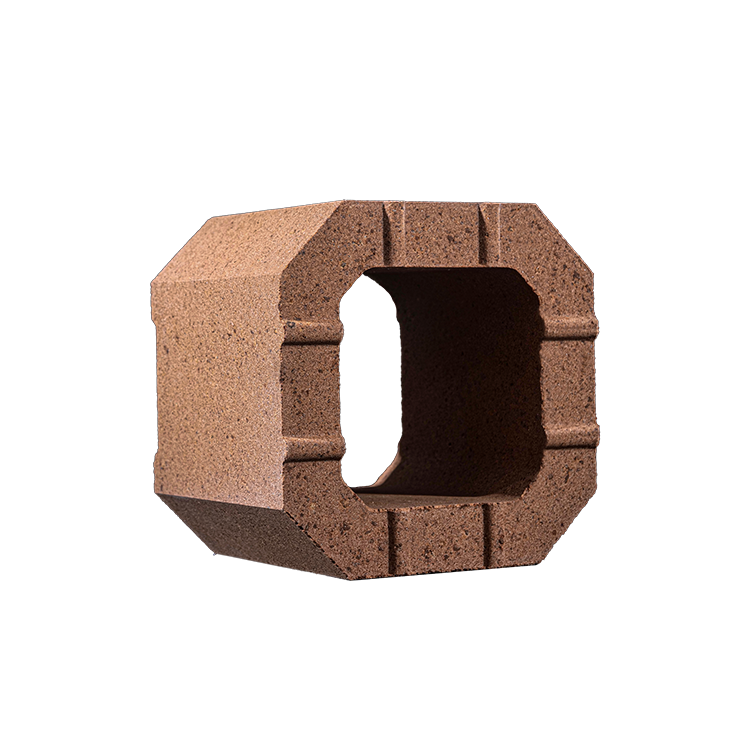

Magnesia zirconia brick

Introduction

:

Magnesia zirconia brick adopts high purity fused magnesite and synthetic sintered magnesia as the main material, after high pressure forming, high temperature firing, excellent erosion resistance to alkali metal, oxide and sulfide. The magnesia zirconia bricks are of high density( bulk density)greater than 3.08g/cm3. It is resistant to alkaline erosion atmosphere basic slag corrosion, it is widely used in glass furnace, regenerative chamber, cement kiln, electric steelmaking furnace and nonferrous metallurgy smelting.

The characteristics of magnesia zirconia bricks: 1.Alkali resistance 2.Resistance to slag 3.The spalling resistance 4.High temperature resistance

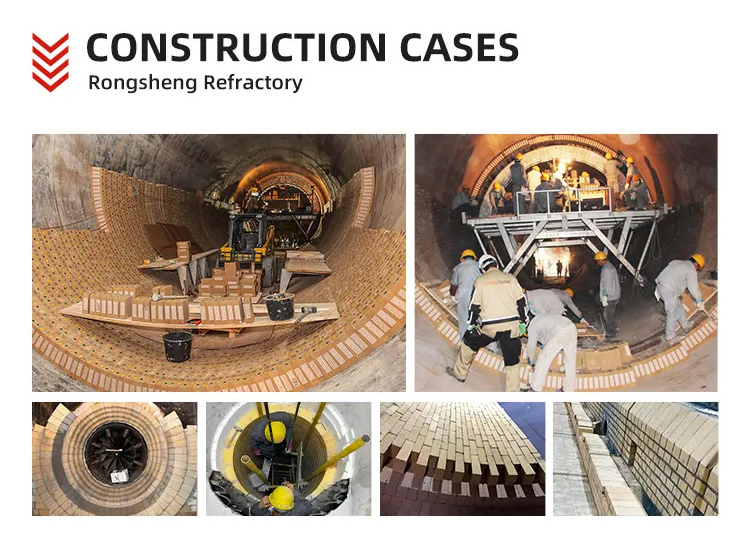

The application of magnesia zirconia bricks: Magnesia zirconia bricks are mainly used in regenerative chamber of glass furnace.

The characteristics of magnesia zirconia bricks: 1.Alkali resistance 2.Resistance to slag 3.The spalling resistance 4.High temperature resistance

The application of magnesia zirconia bricks: Magnesia zirconia bricks are mainly used in regenerative chamber of glass furnace.

Technical Data

|

Item

|

Magnesia-Zircon Brick

|

|

|

||

|

|

TY-MZ8

|

TY-MZ10

|

TY-MZ13

|

||

|

MgO% ≥

|

80

|

75

|

70

|

||

|

ZrO2 %≥

|

8

|

10

|

13

|

||

|

Apparent Porosity%≤

|

19

|

18

|

18

|

||

|

Bulk Density (g/cm3)≥

|

2.95

|

3.00

|

3.05

|

||

|

Cold Crushing Strength (MPa)≥

|

50

|

45

|

40

|

||

|

Refractoriness Under Load°C≥

|

1600

|

1550

|

1600

|

||

|

Thermal Shock Resistance(950-wind cold)≥

|

10

|

10

|

10

|

||

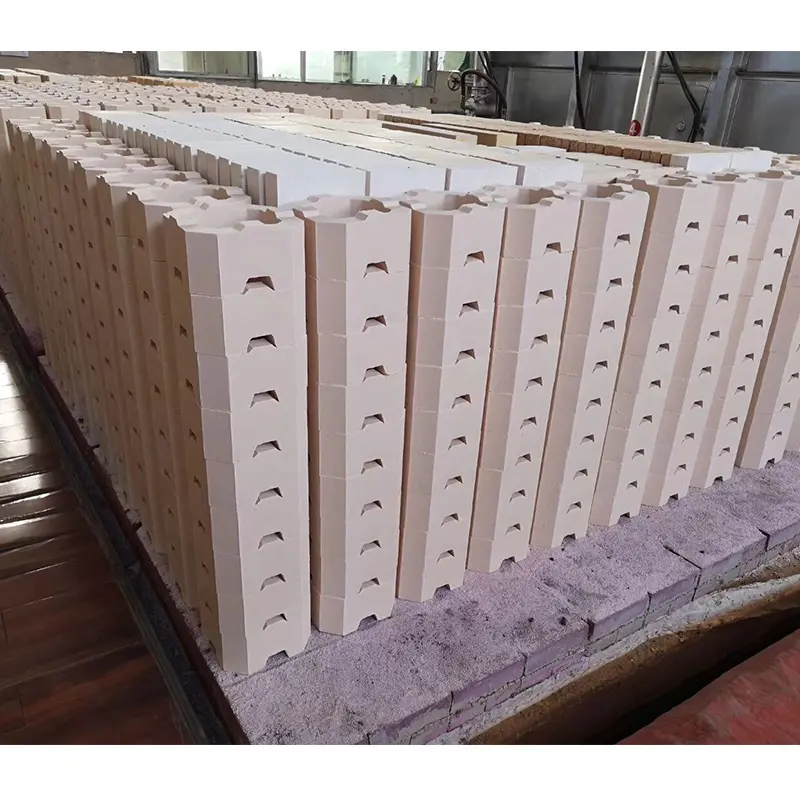

Our Advantages

There are 240 staffs in Rongsheng Company, of which 12 is senior professional technician. Annual production capacity is up to 60000 tons. There are light and heavy weight materials production lines and all kinds of complete production, testing and check equipment, of which there are 10 series shaped press machine that from 400 tons to 1000 tons and two hyperthermia tunnel kilns whose length are 148m and 118m.

Rongsheng Refractory has established complete quality system and conducted quality control through the whole staff and process that from raw materials, production, check and various parts strictly according to ISO9001 standard and with the professional checker at each level to take good product and service as the top goal.

Product packaging

The bricks are packed on wooden pallet with papers in each layer and PP film wrapped outside of the whole pallet.

Hot Searches