- Product Details

- {{item.text}}

Quick Details

-

Frequency:

-

20KHZ

-

Welding Area:

-

0~300mm Diameter, 150MM

-

Dimensions:

-

L425*W630*H920

-

Use:

-

ultrasonic plastic spot welding mchine

-

Weight (KG):

-

95 KG

-

Madel:

-

HJ-2010G

-

Frenquency:

-

20KHZ

-

Output Power:

-

2000

-

Dimension:

-

L425*W630*H920

-

Weight:

-

95KG

-

Welding Time:

-

0.01-9.99S/Time

-

Product name:

-

ultrasonic plastic spot welding mchine

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Hongjin

-

Voltage:

-

110V/220V/380V/Customize

-

Frequency:

-

20KHZ

-

Welding Area:

-

0~300mm Diameter, 150MM

-

Dimensions:

-

L425*W630*H920

-

Use:

-

ultrasonic plastic spot welding mchine

-

Weight (KG):

-

95 KG

-

Madel:

-

HJ-2010G

-

Frenquency:

-

20KHZ

-

Output Power:

-

2000

-

Dimension:

-

L425*W630*H920

-

Weight:

-

95KG

-

Welding Time:

-

0.01-9.99S/Time

-

Product name:

-

ultrasonic plastic spot welding mchine

ultrasonic plastic welding mchine

welds the machine:

The supersonic wave plastic welding principle is produces 15-40KHZ by the generator the high frequency signal,through trades can the system,transforms the signal into the high frequency mechanical vibrations,simultaneously adds with the high pressure on the plastic product work piece,causes passing on place through the work piece surface and the intrinsic intermolecular friction to connection temperature increment,when the temperature achieved when this works itself melting point,causes the work connection rapid melting,subsequently fills crevice to the connection between ,when vibrates stops,at the same time the work cools the setting under the certain pressure,then achieves the perfect welding,The supersonic wave welding is the welding heat plastic,plastic product high technology,each kind of thermosplastic rubber may use supersonic wave welding processing,but does not have add the solveent,the cementation medicinal preparation or other auxiliaries,its merit is the increase multiple productivity,reduces the cost,Improve the product quality.

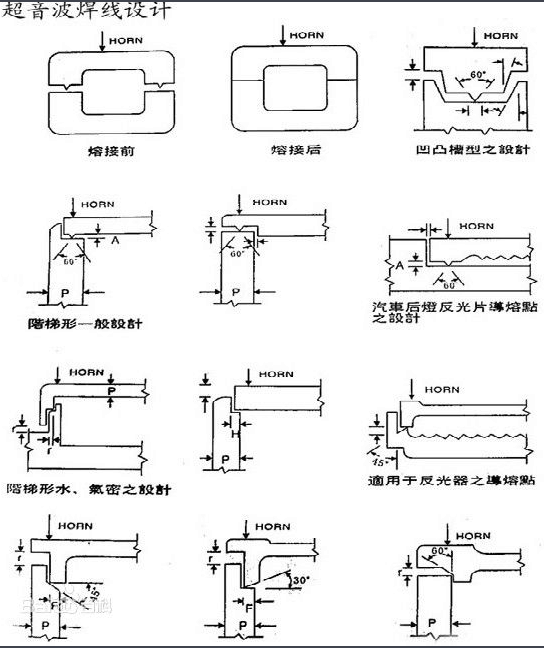

Ultrasonic welding composition plane desgin

Main Features

Export standard wooden case