- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220v/380V

-

Weight:

-

25 KG

-

Dimension(L*W*H):

-

800x500x1400mm

-

Marketing Type:

-

New Product 2024

-

Product name:

-

PSA Oxygen Generator

-

Application:

-

Hospital , Farms , aquaculture , industrial , home

-

Technology:

-

Pressure Swing Adsorbtion (PSA)

-

Capacity:

-

1lL-200L

-

Certification:

-

ISO9001

-

Material:

-

Stainless Steel 304

-

Oxygen Purity:

-

93.00%----99.999%

-

Advantage:

-

High Efficiency Low Cost

-

Oxygen producing method:

-

PSA Pressure Swing Adsorption

-

Feature:

-

Stable Oxygen Production

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DIKE

-

Production Rate:

-

1L-200L

-

Voltage:

-

220v/380V

-

Weight:

-

25 KG

-

Dimension(L*W*H):

-

800x500x1400mm

-

Marketing Type:

-

New Product 2024

-

Product name:

-

PSA Oxygen Generator

-

Application:

-

Hospital , Farms , aquaculture , industrial , home

-

Technology:

-

Pressure Swing Adsorbtion (PSA)

-

Capacity:

-

1lL-200L

-

Certification:

-

ISO9001

-

Material:

-

Stainless Steel 304

-

Oxygen Purity:

-

93.00%----99.999%

-

Advantage:

-

High Efficiency Low Cost

-

Oxygen producing method:

-

PSA Pressure Swing Adsorption

-

Feature:

-

Stable Oxygen Production

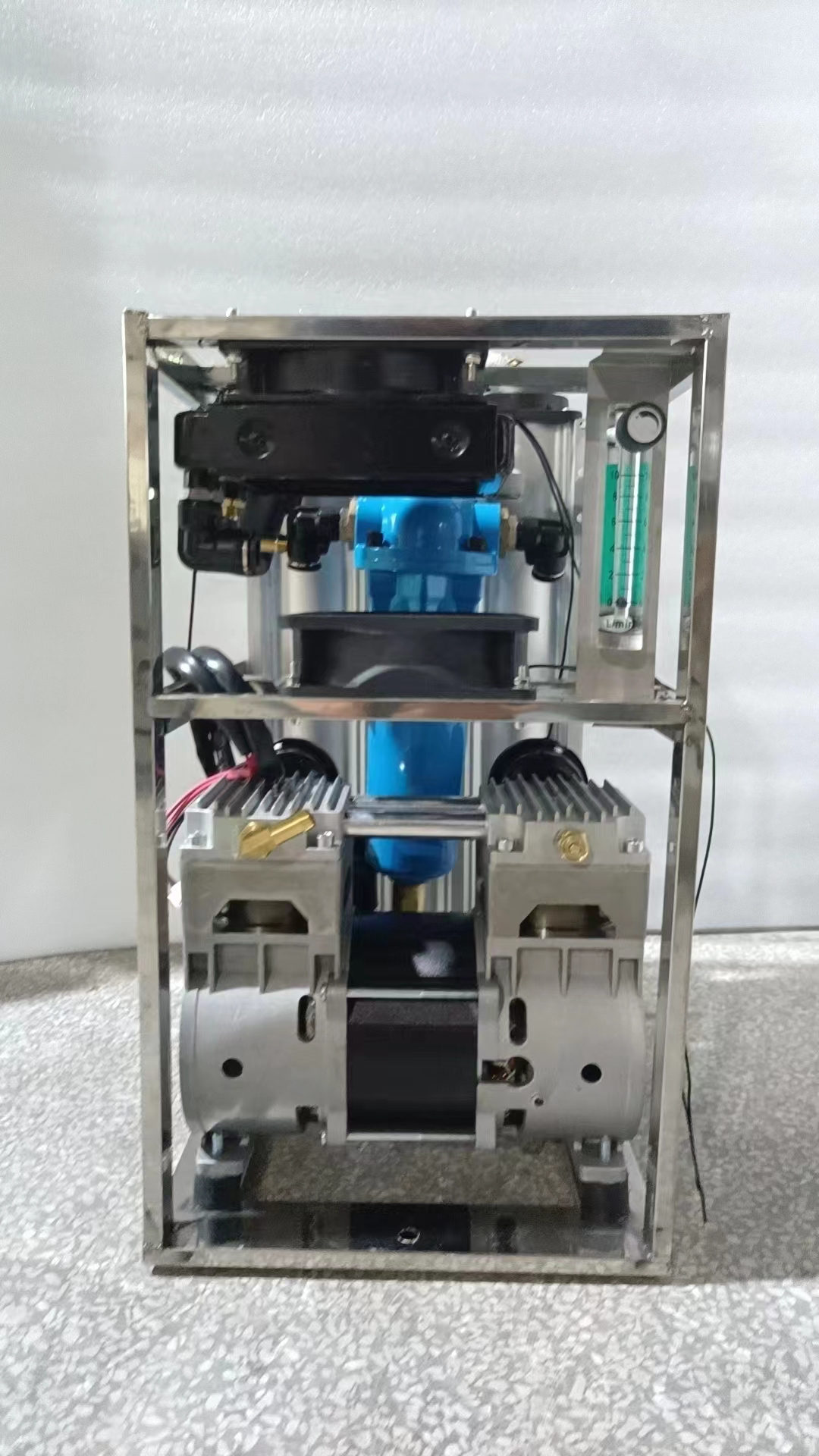

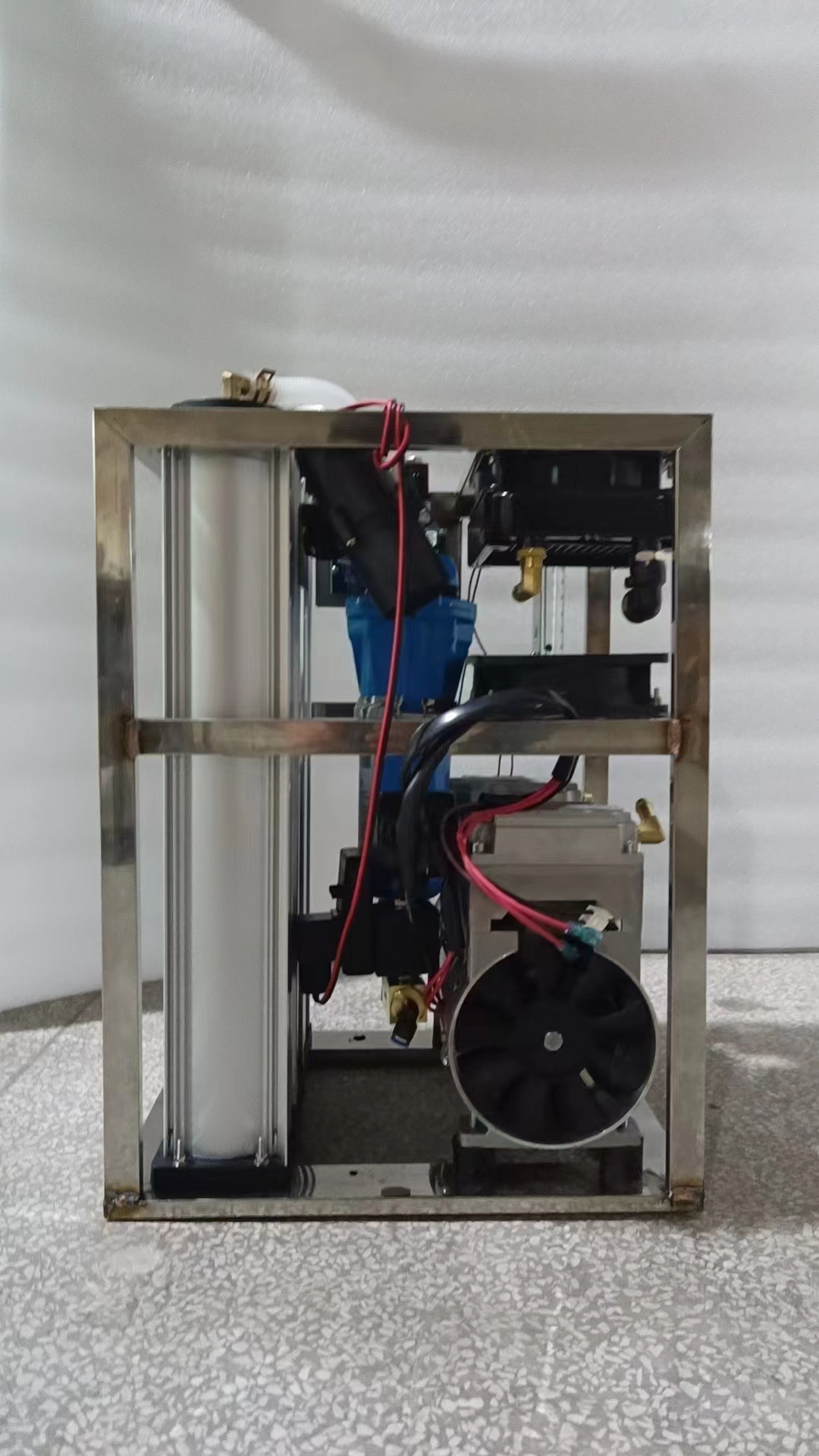

5 liters 10 liters 20 liter aquaculture portable continuous flow psa oxygen concentrator with purifier

Portable PSA OXYGEN GENERATOR

Pressure swing adsorption (PSA) is a technology used to separate some gas species from a mixture of gases under pressure according to the species' molecular characteristics and affinity for an adsorbent material.

Specific adsorptive materials (e.g., zeolites, activated carbon, molecular sieves, etc.)are used as a trap,

preferentially adsorbed the target gas species at high pressure. The process then swings to low pressure to

desorb the adsorbed material.

Technique principle

1. Purified air drying treatment, role of pressure swing adsorption to achieve separation of oxygen and nitrogen

2. Due to selective adsorption characteristics of zeolite, nitrogen molecule is adsorbed in zeolite, oxygen generator in gas phase

obtained, as product output.

3.System device has two absorption tower, production of oxygen adsorption tower, tower desorption recycling, pay latent and continue.

Advantage:

1. Simple device for air compressors, only cooler.

2. Molecular sieve requirements is relatively low, the same oxygen equipment, quantity of molecular sieve.

3. Small size , so the cost is relatively low.

4. Requires relatively low degree of automation of the entire equipment, air compressors, freeze dryer/condenser and oxygen

separately start-stop control or joint control.

Pressure swing adsorption (PSA) is a technology used to separate some gas species from a mixture of gases under pressure according to the species' molecular characteristics and affinity for an adsorbent material.

Specific adsorptive materials (e.g., zeolites, activated carbon, molecular sieves, etc.)are used as a trap,

preferentially adsorbed the target gas species at high pressure. The process then swings to low pressure to

desorb the adsorbed material.

Technique principle

1. Purified air drying treatment, role of pressure swing adsorption to achieve separation of oxygen and nitrogen

2. Due to selective adsorption characteristics of zeolite, nitrogen molecule is adsorbed in zeolite, oxygen generator in gas phase

obtained, as product output.

3.System device has two absorption tower, production of oxygen adsorption tower, tower desorption recycling, pay latent and continue.

Advantage:

1. Simple device for air compressors, only cooler.

2. Molecular sieve requirements is relatively low, the same oxygen equipment, quantity of molecular sieve.

3. Small size , so the cost is relatively low.

4. Requires relatively low degree of automation of the entire equipment, air compressors, freeze dryer/condenser and oxygen

separately start-stop control or joint control.

FEATURES AT A GLANCE

|

Model

|

Unit

|

FY-03-93

|

FY-05-93

|

FY-10-93

|

FY-15-93

|

FY-20-93

|

||||||

|

Oxygen output

|

L/min

|

3

|

5

|

10

|

15

|

20

|

||||||

|

Size

|

mm

|

380x260x730mm

|

380x260x730mm

|

450x320x930mm

|

500x380x1100mm

|

550x400x1250mm

|

||||||

|

Power supply

|

V/Hz

|

220/50

|

220/50

|

220/50

|

220/50

|

220/50

|

||||||

|

Concentration

|

%

|

≥93%

|

≥93%

|

≥93%

|

≥93%

|

≥93%

|

||||||

|

Weight

|

kg

|

35

|

38

|

48

|

58

|

68

|

||||||

|

Outlet pressure

|

Mpa

|

0.05

|

0.05

|

0.05

|

0.05-0.1

|

0.05-0.1

|

||||||

|

Requirements of Air Condition:

|

|

|

|

|

|

|

||||||

|

Temperature

|

-5~40℃

|

|

|

|

|

|

||||||

|

Humidity

|

60-80%

|

|

|

|

|

|

||||||

|

Air with Dust Content

|

<=20mg/m3

|

|

|

|

|

|

||||||

|

Air with H2S, SO2

|

<=5ppm

|

|

|

|

|

|

||||||

|

Air with CO2

|

<=250ppm

|

|

|

|

|

|

||||||

|

Air with C2H2

|

<=0.5ppm

|

|

|

|

|

|

||||||

|

Air with CmHm

|

<=20ppm

|

|

|

|

|

|

||||||

|

Air with Acidic Gas

|

No more Pungent Smell and Corrosive smell

|

|

|

|

|

|

||||||

|

Ventilation

|

Dry and cool environment

|

|

|

|

|

|

||||||

PRODUCT CONFIGURATION

The oxygen generator adopts the original imported lithium and low siliconoxygen molecular sieves, which can produce oxygen quickly andthe oxygen concentration is high and stable

DURABLE STABLE COMPRESSOR

Save energy consumption, stable and lasting, less mechanical wear

HIGH CONCENTRATIONCONTINUOUS OXYGEN SUPPLY

Taking air as raw material has the advantages of low operatingcost, low energy consumption and high efficiency

Application scenarios

Application scenarios

Hotel room disinfection;Home interior;School kindergarten;Pet shop;Car disinfection;Hospital sterilization;

fish farming;

Breeding

Hot Searches