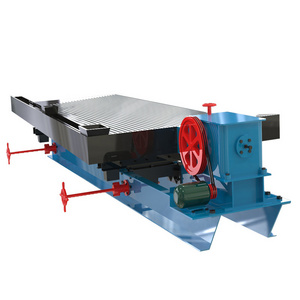

This machine is composed of three parts, i.e. head of shaking table, surface of shaking table, as well as bearing and adjusting gradient.

1.Head of shaking table: This is eccentric connecting-rod type mechanism. The motor drives the eccentric shafts to rotate and the connecting rod to move up and down. When the connecting rod pushes down the toggle plate compression spring, the pull rod drives the table surface to move in the direction of table head. When the connecting rod pushes it upward, it, through the spring tension, drives the table surface to move in the opposite direction. When they are linked, the rotating motion of eccentric shaft is changed into horizontal alternating differential motion of table surface.

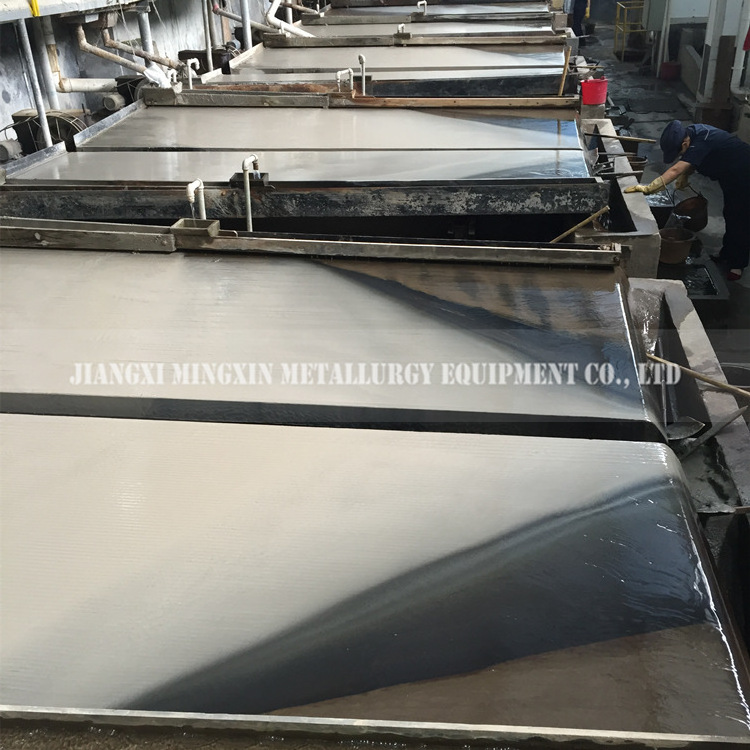

2.Shaking table for gold table surface: It is mainly composed of vibrating roof, steel skeleton, glass fiber reinforced plastics and wear-proof surface, feed water tank, feed chute, and draw bar. The table surface adopts steel skeleton FRP composite structure. That is, glass fiber reinforced plastics are pasted on steel skeleton to form a solid glass fiber reinforced plastic surface. Its above uses abrasion-proof materials to make surface and riffle (notch groove).

3.Bearing and Adjusting Gradient Mechanism: Shaker table for gold The bearing and adjusting gradient mechanism is mainly composed of shaking support plate, adjusting seat board, saddle seat, and adjusting screw rod. The shaking support plate enables the table surface to make arc forward and backward alternating movement on vertical plane. The shaking support plate and shaking box are fixed on the adjusting seat board with gripping channel steel. When hand wheel regulating screw rod is used to get the adjusting seat board to rotate on the saddle seat, the Transverse gradient of table surface can be adjusted.