- Product Details

- {{item.text}}

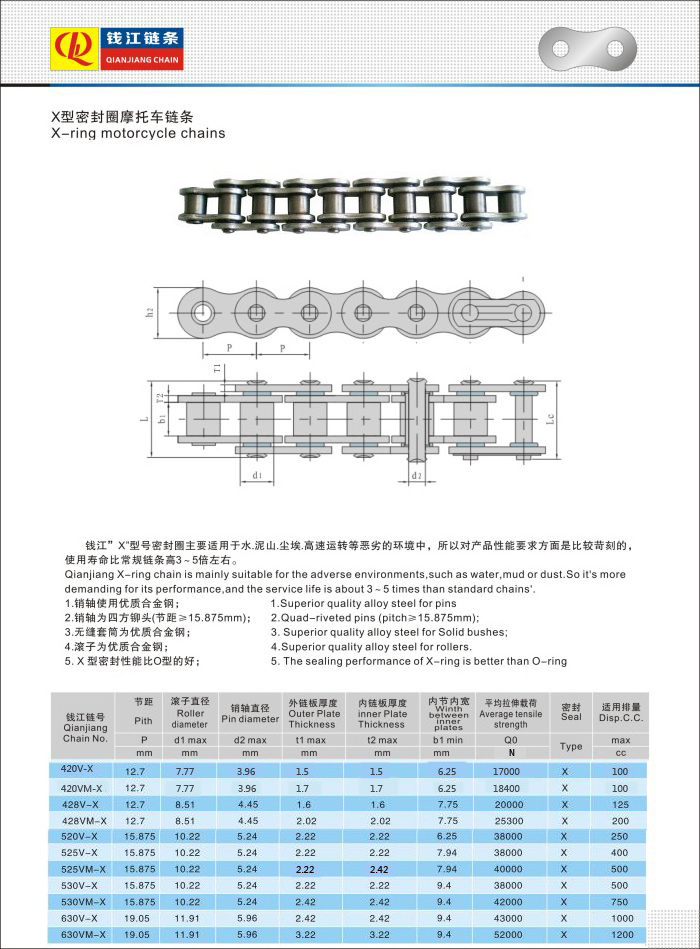

Quick Details

-

Material:

-

Alloy

-

Average tensile strength:

-

17KN

-

OEM:

-

Avaliable

-

Thickness:

-

1.52mm

-

Application:

-

Motorcycle /ATV

-

Pitch:

-

12.7mm

-

Surface treatment:

-

Painting

-

Model:

-

420 o ring red, blue, green, yellow gold colored motorcycle chain

-

Heat treatment:

-

Quenching / Tempering

-

Packing:

-

Polybag+box+carton

-

Certification:

-

ISO9001

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

QJ / YF / HQL

-

Warranty:

-

16000KM

-

Material:

-

Alloy

-

Average tensile strength:

-

17KN

-

OEM:

-

Avaliable

-

Thickness:

-

1.52mm

-

Application:

-

Motorcycle /ATV

-

Pitch:

-

12.7mm

-

Surface treatment:

-

Painting

-

Model:

-

420 o ring red, blue, green, yellow gold colored motorcycle chain

-

Heat treatment:

-

Quenching / Tempering

-

Packing:

-

Polybag+box+carton

-

Certification:

-

ISO9001

Wholesale 420 o ring red, blue, green, yellow gold colored motorcycle chain for Honda,Suzuki, Yamaha etc

The products are made of high quality alloy steel production. The plates are punched and squeezed bores by precision technology. The pin, bush, roller are machined by high-efficiency automatic equipment and automatic grinding equipment, then through heat treatment of carburization, carbon and nitrogen protection mesh belt furnace, surface blasting process etc. Assembled precision by Internal hole position, spin riveted by pressure to ensure the performance of the entire chain.

|

1)Raw materials↓ |

|

|

surface checking |

metallic structure inspection |

|

sizes checking |

hardness inspection |

|

2)Manufacture process of chain parts ↓ |

|

|

Punching hole |

polishing |

|

blanking |

shot blasting |

|

curving |

deburrs |

|

cold forging |

bending |

|

grooving |

calibrate |

|

chamfering |

shave hole |

|

grinding plane and hole |

rolling folding |

|

grinding cylindrical surface |

sizing |

|

centreless grinding |

oiling |

|

3)Heat treatment ↓ |

|

|

quenching |

bluing |

|

low temperature temper |

yellowing |

|

duplex quenching |

phosphatizing |

|

through hardening |

washing |

|

oil quenching |

cooling |

|

liquid carburizing |

hardness inspection |

|

annealing |

metallic structure inspection |

|

4)Assembling↓ |

|

|

automatic choice materials |

running in |

|

measuring chain length |

pre-stretch |

|

measuring chain torque |

high speed running in test |

|

tensile strength test |

endurance testing of chain |

|

5)Packing↓ |

|

|

end inspection |

high temperature greasing |

|

clean oiling |

cooling |

|

Anti-rust oiling/greasing |

put in polybag,box,carton etc. |

1. Any of your kind inquiries of chains would be replied within 24 hours.

2. Well-trained and experienced sales staffs will reply all your concerns in fluent English.

3. OEM services are available with us, our professional designer would make your private idea into being.

4. Protection of your sales area, ideas of design and all your private information.

5. We are committed to ensuring that only products of the highest quality are delivered to our customers.

6. Soonest delivery time,if necessary by express or by air or by sea.