- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

customized

-

Power (kW):

-

30-90

-

Weight (KG):

-

2000 KG

-

Certification:

-

CE, SGS

-

heating way:

-

steam boiler/electric

-

usage:

-

rubber vulcanizing

-

material:

-

ss304 or Q345R

-

vulcanizing way:

-

hot steam/hot air

-

control system:

-

automatic with PLC/semi-automatic

-

function:

-

high temperature high pressure curing

-

Name:

-

Tire Vulcanizer Repair Electric Retreading Machine

-

Capacity:

-

as per your productivity

-

Machine Type:

-

pressure vessel

-

Suitable tire:

-

Car Truck Motocycle

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Ritong

-

Voltage:

-

as per the client's factory

-

Dimension(L*W*H):

-

customized

-

Power (kW):

-

30-90

-

Weight (KG):

-

2000 KG

-

Certification:

-

CE, SGS

-

heating way:

-

steam boiler/electric

-

usage:

-

rubber vulcanizing

-

material:

-

ss304 or Q345R

-

vulcanizing way:

-

hot steam/hot air

-

control system:

-

automatic with PLC/semi-automatic

-

function:

-

high temperature high pressure curing

-

Name:

-

Tire Vulcanizer Repair Electric Retreading Machine

-

Capacity:

-

as per your productivity

-

Machine Type:

-

pressure vessel

-

Suitable tire:

-

Car Truck Motocycle

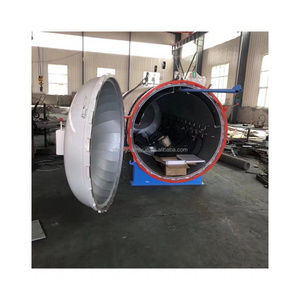

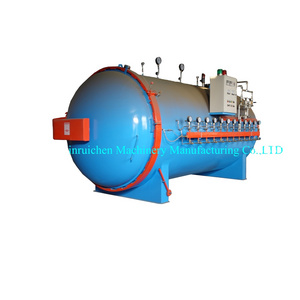

Tire Vulcanizer Repair Electric Retreading Machine

Mainly used for the tyre retreading.

Tire Vulcanizer Repair Electric Retreading Machine

Specs

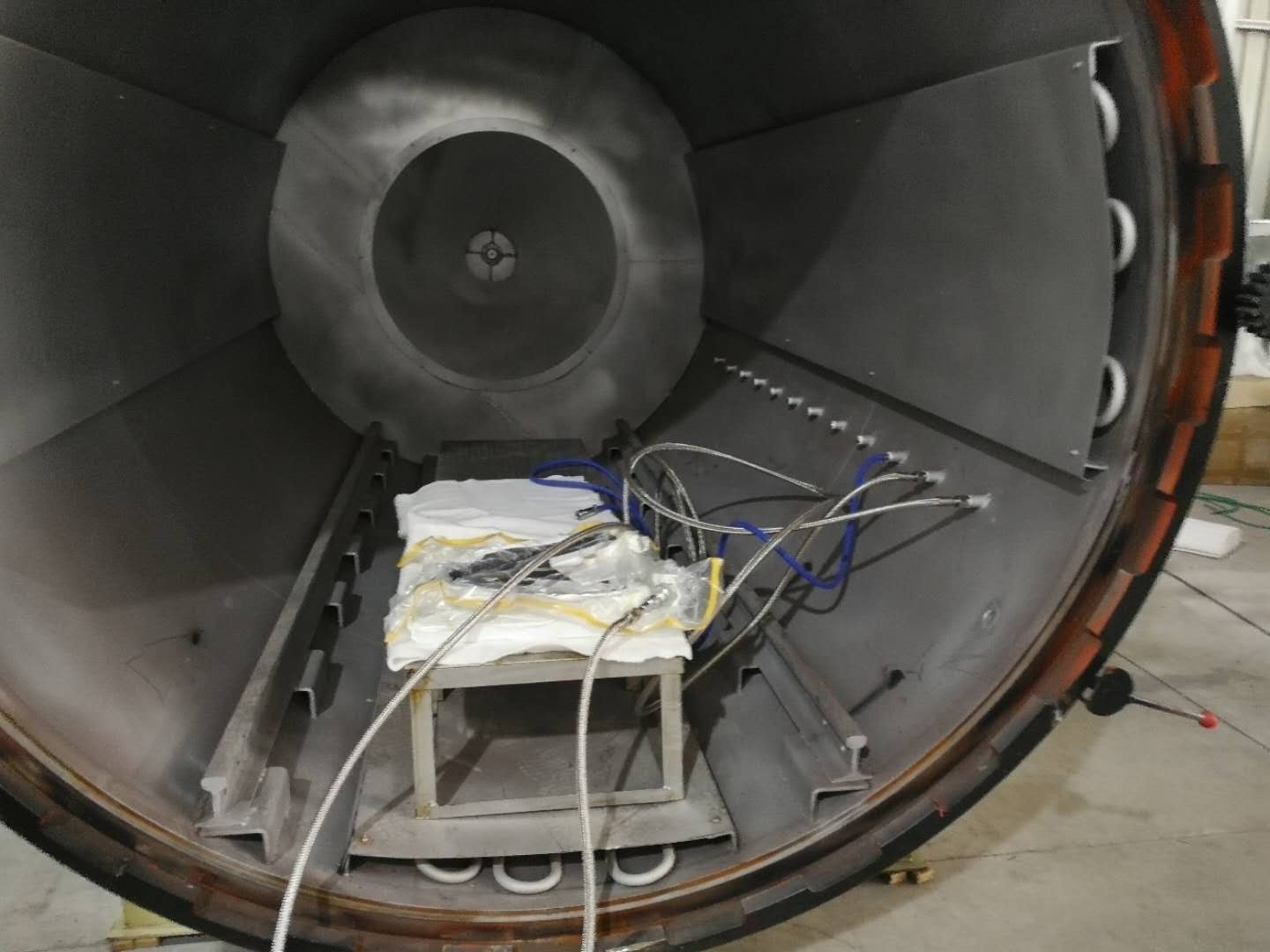

Working principle for electricity steam vulcanizing autoclave

Electric heated tubes are arranged in the bottom of the tank according to certain rules, the heat exchanger linked the electric heated tubes and the water channel. The height of the sink is 5~15mm. The steam which produced by electric heated tubes and water spread from down to up evenly until turn into condensate water pour into the sink after touched the wall of tank and then heat again. The temperature of the tank evenly and the pressure has no error, so it can prevent the different quality of the product because of the uneven temperature and pressure. After set working procedures, the heating, heat preservation, vulcanization and etc can be finished by automatic control system. The equipment stop working and give alarm after all procedures finished.

Technical parameter

|

Item |

800 |

1200 |

1500 |

1700 |

2000 |

2600 |

|

Inner diameter(mm) |

800 |

1200 |

1500 |

1700 |

2000 |

2600 |

|

Canister length(mm) |

22000 |

3000 |

3000 |

4000 |

5000 |

10000 |

|

Number of lid sawtooth |

12 |

12 |

14 |

14 |

16 |

24 |

|

thickness of lid (mm) |

10 |

10 |

10 |

10 |

16 |

14 |

|

Thickness of the tank body(mm) |

10 |

10 |

10 |

10 |

12 |

14 |

|

Working pressure(Mpa) |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

0.55 |

|

Dimensions(mm) (length*width*height) |

22766*1445

|

4010*1575

|

3960*2150

|

4925*2162

|

6200*2590

|

11722*3360

|

|

Weight(Kg) |

5580 |

2017 |

2950 |

3835 |

6500 |

16775 |

Ranges of application

It is mainly used for rubber tyre retreading, reclaimed rubber desulphurization, wire, cable, tape, rubber rollers and other rubber products vulcanization. styrene-butadiene rubber thermoplastic refining, drying wood, Chinese medicine sterilization, oxidation of aluminum products, carbonization of bamboo products, Also widely used in the gypsum and its products and other materials autoclaving.

We will delivery your goods by LCL/20' FCL/40'FCL depending on your order. Before delivery, our professional engineer will do trial run for each machine to check and confirm everything is work a ble, you also can come to our factory for tes t ing together with us.whe n loading, our workers will fix the machine tightly in the container to ensure the safety in the transportation.

Site Planning and Proposal Design

to provide targeted, energy-efficiency technology solution according to

the request of client, and to plan the supporting facilities of sterilization equipment in details based on customer’s site.

Turnkey Service

From technical scheme design to project implementation and commissioning, sterilization equipment specialists provide technical services in the whole process to save your worry and effort, to experience one-stop engineering.

Periodic testing and maintenance of key equipment

Reduce equipment failure and abnormal shutdown and improve reliabiligy, professional service for emergency fault protects equipment and prolong life to reduce overall operating costs

Overview of quality control

1. Check all the carbon steel/ stainless steel assembly unit material, ensure the Product from the Ritong Company quality leadership. One by one check all the original materials of main part when in manufacture(main check the content of indicators Ni, S, C, P, Cr), can get the checking end within 15-20mins, the material used in fabrication of pressure vessels parts serial no. To put in storage, unqualified parts are all returned to the factory. Refine covered 100% spare parts .

2.Quick door opening chain lock device Use the quality cylinder as special protection components, at the same time to use the optoelectronic switch, mechanical interlock three layers lock system, ensure the safety of the door opening and close.

3.Level of the protection for the control system and cable is 2P65. Use the industrial computer human-machine interface control, can optional the paper or without paper recorder.

4.Whole cover the the insulation for the autoclave, saving energy and reducethe consumption.

The machine from Ritong manufacture can as per the client’ s requirement, to do the insulation for the cylinder, head and pipes, saving energy and reduce the consumption, minimize the curing cost for the client.

5.Zero distance service marketing idea, full implementation of "three five-star” service

Ritong company opened a 24-hour service hotline: +86 183 6635 0187. and in the service of import "first asking responsibility system", Full implementation of "zero distance, nanny style" star service, Service problems such as calls, letter, full-time technical service person reply customer first time about the preparation time, the solution of problem solving time , and plan to customer company.