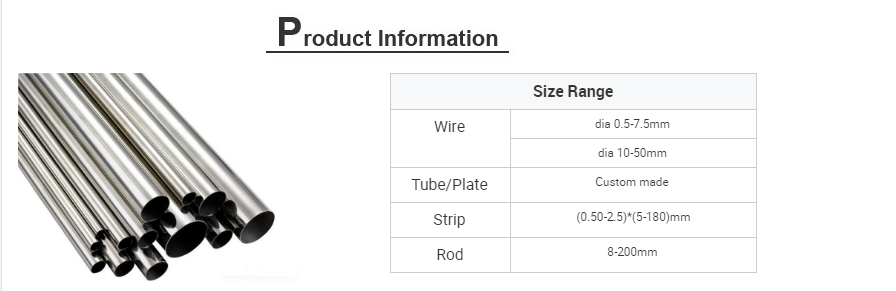

- Product Details

- {{item.text}}

Quick Details

-

Elongation (≥ %):

-

standard

-

Place of Origin:

-

Jiangsu, China

-

Application:

-

sealing glass

-

Grade:

-

Iron-Nickel-Co

-

Ni (Min):

-

28.5%

-

Model Number:

-

4J28,4J29,4J32,4J33,4J36,4J40,4J50

-

Brand Name:

-

DLX

-

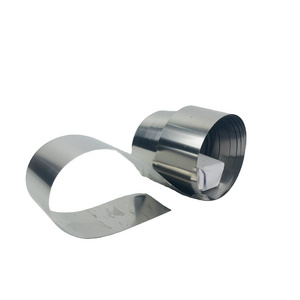

Shape:

-

strip

-

Surface:

-

Bright Annealed

-

Standard:

-

AISI,ASTM,SUS,JIS,GB

-

Certificate:

-

ISO9001/ROHS

-

Delivery time:

-

7-20 Days

-

Product name:

-

soft magnetic alloy

-

Condition:

-

Soft Annealed

Quick Details

-

Resistance (μΩ.m):

-

Standard

-

Powder Or Not:

-

Not Powder

-

Ultimate Strength (≥ MPa):

-

Strandard

-

Elongation (≥ %):

-

standard

-

Place of Origin:

-

Jiangsu, China

-

Application:

-

sealing glass

-

Grade:

-

Iron-Nickel-Co

-

Ni (Min):

-

28.5%

-

Model Number:

-

4J28,4J29,4J32,4J33,4J36,4J40,4J50

-

Brand Name:

-

DLX

-

Shape:

-

strip

-

Surface:

-

Bright Annealed

-

Standard:

-

AISI,ASTM,SUS,JIS,GB

-

Certificate:

-

ISO9001/ROHS

-

Delivery time:

-

7-20 Days

-

Product name:

-

soft magnetic alloy

-

Condition:

-

Soft Annealed

Products Description

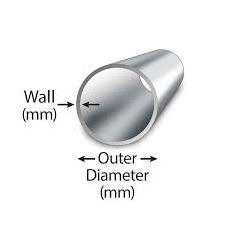

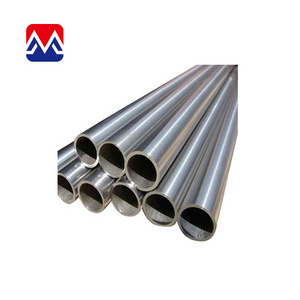

ASTM F15 Iron Nickel Cobalt Kovar alloy 4J29 tube/pipes

Glass sealed and controlled expansion Kovar alloys

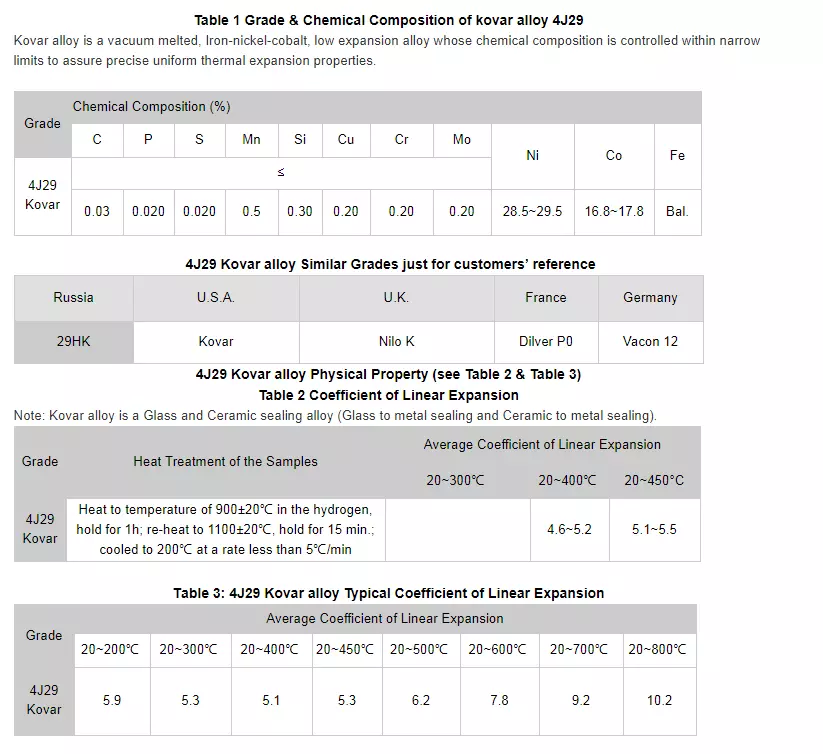

* kovar alloy, ASTM F15, Nilo-K, UNS K94610 (FeNi29Co17), Chinese 4J29

*Specifications:ASTM F15; DIN 17745; S.E.W. 385; Werkstoff Nr. 1.3981; AFNOR NF A54-301

Kovar Alloy, also know as ASTM F-15, NILO K, Pernifer 2918, Rodar, and Dilvar P1 is Nickel-Iron-Cobalt, controlled expansion alloy containing 29% Nickel.

It’s coefficient of expansion (which decreases with rising temperature to the inflection point), matches the expansion rate of borosilicate glasses and aluminia ceramics.

Applications include glass to metal seals in applications requiring high reliability or resistance to thermal shock, ie.high~power transmitting valves, transistor leads and heaters and photography flash bulbs.

* kovar alloy, ASTM F15, Nilo-K, UNS K94610 (FeNi29Co17), Chinese 4J29

*Specifications:ASTM F15; DIN 17745; S.E.W. 385; Werkstoff Nr. 1.3981; AFNOR NF A54-301

Kovar Alloy, also know as ASTM F-15, NILO K, Pernifer 2918, Rodar, and Dilvar P1 is Nickel-Iron-Cobalt, controlled expansion alloy containing 29% Nickel.

It’s coefficient of expansion (which decreases with rising temperature to the inflection point), matches the expansion rate of borosilicate glasses and aluminia ceramics.

Applications include glass to metal seals in applications requiring high reliability or resistance to thermal shock, ie.high~power transmitting valves, transistor leads and heaters and photography flash bulbs.

Specification

|

Alloy Type

|

Trade Name |

UNS No. |

Specifications |

Forms Of Supply

|

|

|

|

|||

|

|

|

|

|

Rod

|

Strip

|

Wire

|

Sheet

|

|||

|

Ni29Co17

|

Kovar

|

K94610

|

ASTM F15

|

√

|

√

|

√

|

√

|

|||

|

FeNi36

|

Invar 36

|

K93603

|

ASTM 1684

|

√

|

√

|

|

√

|

|||

|

FeNi32Co5

|

Super Invar 32-5

|

KI93500

|

ASTMF1684

|

√

|

√

|

|

√

|

|||

|

FeNi27Co25

|

Ceramvar

|

F1466

|

ASTMF1466

|

√

|

√

|

√

|

√

|

|||

|

FeNi42

|

Alloy 42

|

K94100

|

ASTM F30

|

√

|

√

|

|

√

|

|||

|

FeNi46

|

Alloy 46

|

K94600

|

ASTM F30

|

√

|

√

|

|

√

|

|||

|

FeNi48

|

Alloy 48

|

K94800

|

ASTMF30

|

√

|

√

|

|

√

|

|||

|

FeNi50

|

Alloy 52

|

K95050

|

ASTM F30

|

√

|

√

|

√

|

√

|

|||

|

Item

|

1J33

|

3J01

|

3J9

|

4J29

|

4J32

|

4J33

|

4J45

|

FeNi50

|

Invar36

|

||||||||

|

C

|

≤0.05

|

≤0.05

|

0.22-0.26

|

≤0.03

|

≤0.05

|

≤0.03

|

≤0.05

|

≤0.05

|

≤0.1

|

||||||||

|

Mn

|

≤0.05

|

≤1.00

|

1.80-2.20

|

≤0.5

|

0.2-0.6

|

≤0.5

|

≤0.8

|

≤0.8

|

≤0.5

|

||||||||

|

Fe

|

Rest

|

|

|

|

|

|

|

|

|

||||||||

|

P

|

≤0.020

|

≤0.020

|

≤0.03

|

≤0.02

|

≤0.02

|

≤0.02

|

≤0.02

|

≤0.02

|

≤0.006

|

||||||||

|

S

|

≤0.020

|

≤0.020

|

≤0.020

|

≤0.02

|

≤0.02

|

≤0.02

|

≤0.02

|

≤0.02

|

≤0.04

|

||||||||

|

Si

|

0.30-0.6

|

≤0.80

|

1.30-1.70

|

≤0.3

|

≤0.2

|

≤0.3

|

≤0.3

|

≤0.3

|

≤0.35

|

||||||||

|

Ni

|

32.8-33.8

|

34.5-36.5

|

9.0-10.5

|

28.5-29.5

|

31.5-33

|

28.5-29.5

|

44.5-45.5

|

49.5-50.5

|

35-38

|

||||||||

|

Al

|

1.0-2.0

|

1.00-1.80

|

--

|

--

|

--

|

--

|

≤0.1

|

≤0.1

|

--

|

||||||||

|

Co

|

--

|

--

|

--

|

16.8-17.8

|

3.2-4.2

|

16.8-17.8

|

-

|

-

|

-

|

||||||||

|

Ti

|

-

|

2.70-3.20

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

||||||||

|

Cu

|

-

|

--

|

--

|

--

|

≤0.2

|

0.4-0.8

|

≤0.2

|

--

|

--

|

||||||||

|

Cr

|

--

|

11.5-13.0

|

19.0-20.5

|

≤0.2

|

--

|

≤0.2

|

--

|

--

|

--

|

||||||||

|

Mo

|

--

|

--

|

1.60-1.85

|

≤0.2

|

--

|

≤0.2

|

--

|

--

|

--

|

||||||||

Packing&Shipping

About Us

CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and etc, in the form of wire, strip, ribbon, bar, tube, plate.

FAQ

What is your working time?

Monday-Saturday : 7:30AM-17:00PM (Beijing time, GMT+08.00)

We have public holiday during May.1-3, Oct.1-7 and Chinese New Year holiday . Pls email us during our holiday if u have any question.

Mobile/Whatsapp/Wechat/Skype: +8618961410953

Do you provide free samples?

Yes, we can provide a free sample for testing,buyer should bear all the shipping costs.

What is your payment terms?

T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal

What is the lead time?

Usually sample lead time is 7 days after payment has been confirmed.

Hot Searches