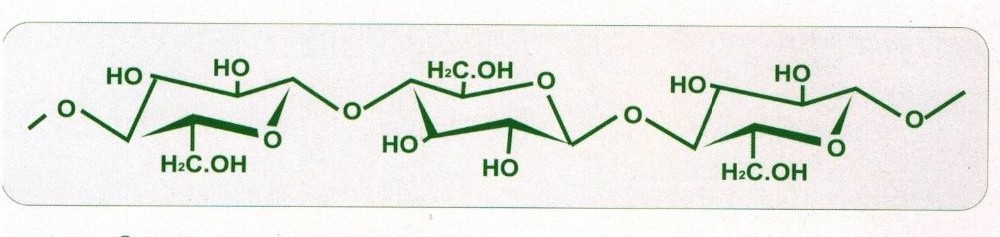

LVJIAN®Ultrastrong cellulose fiber is extracted from natural special tree species and obtained through screening, division, high temperature treatment, neutralization and screening.Its microstructure shows the porous character of belt bending and uneven.Chemical performance is stable, under ordinary conditions, not general solvent, acid, alkali corrosion.

LVJIAN® Ultrastrong cellulose fiber has non-toxic, non-ambiguous, non-pollution, non-radioactive, eco-friendly characteristics which other mineral fiber does not have.

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Workshop

-

Design Style:

-

Industrial

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

LVJIAN

-

Model Number:

-

TM300

-

COLOUR:

-

WHITE

Quick Details

-

Warranty:

-

2 years

-

After-sale Service:

-

Online technical support

-

Project Solution Capability:

-

Others

-

Application:

-

Workshop

-

Design Style:

-

Industrial

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

LVJIAN

-

Model Number:

-

TM300

-

COLOUR:

-

WHITE

LVJIAN®Ultrastrong cellulose fiber

● LVJIAN® Ultrastrong cellulose fiber has excellent natural hydrophilic properties

As cellulose fiber purified from special tree species, it has natural hydrophilic property, and its excellent natural hydrophilic property makes fiber concrete have:

1) strong gripping capacity between concrete and fiber, greatly improving the anti-cracking performance of concrete

2) the dispersion of fiber in concrete is more uniform, which significantly improves the crack resistance of concrete

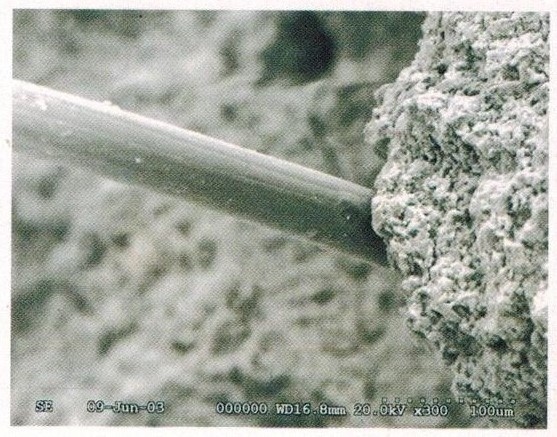

(a) LVJIAN® ultrastrong cellulose fiber surface

adheres to a large amount of cement paste

Strong grip between concrete and fiber

(b) polypropylene fiber surface has no cement

particle adhesion

Weak grip between concrete and fiber

Fiber microscopy under scanning electron microscopy

● LVJIAN ® ultrastrong cellulose fiber unique cavity structure design

1) reduce the hydration heat and improve the early anti-drying shrinkage cracking ability of concrete

2) promote complete cement hydration, and significantly improve concrete density and durability

(a) LVJIAN® ultrastrong cellulose fiber contains

a unique cavity

Cement hydration is complete, improve crack

resistance and durability

(a) Petrographic analysis of LVJIAN® ultrastrong

cellulose fiber concrete

High degree of hydration and no microcracks

LVJIAN ® ultrastrong cellulose fiber unique cavity structure design

● LVJIAN® Ultrastrong cellulose fiber has huge specific surface area

The specific surface area of LVJIAN® ultrastrong cellulose fiber reaches 25,000 c m 2/g, while the specific surface area of ordinary polypropylene synthetic fiber is only about 9001-1,500 c m 2 /g (varies according to diameter and type of fiber).

1) complete cement hydration, promote concrete strength growth, improve density and durability

2) increase the grip strength of concrete, so as to enhance its early crack resistance

(a) LVJIAN® ultrastrong cellulose fiber huge

specific surface area promotes strength growth

and durability of concrete

(b) The relatively small specific surface area of

the polypropylene fiber forms a lower grip

between the fiber and the concrete

Huge specific surface area of LVJIAN® ultrastrong cellulose fiber

● Large fiber quantity and small fiber spacing - improve the crack resistance of concrete

The average number of polypropylene fibers is about 0.03 billion/kg, while the number of LVJIAN® Ultrastrong cellulose fibers can reach 1.59 billion/kg, so the number of LVJIAN® Ultrastrong cellulose fiber is dozens of times that of synthetic fibers such as polypropylene.The fiber spacing calculated according to the fiber spacing theory (calculated according to the content of 0.9kg /m3) is only 0.6m m.According to the fiber spacing theory, the larger the number of fiber , the smaller the fiber spacing in the concrete, and the stronger the anti-early cracking ability of the concrete. So concrete mixed in LVJIAN® ultrastrong cellulose fiber has stronger crack resistance than polypropylene fiber

● LVJIAN® Ultrastrong cellulose fiber has Patent alkali resistant coating -- improve the durability of concrete

The surface of LVJIAN® Ultrastrong cellulose fiber has Patent alkali resistant coating which can protect the fiber and the corrosion resistance of concrete, so as to enhance the durability of concrete.According to the United States ASTM D6942 test method, LVJIAN® Ultrastrong cellulose fiber with Patent alkali resistant coating has excellent alkali resistance, the strength loss in both saturated Ca (OH)2 and 1.0N NaOH strong base solution meet the standard requirements of ASTMD6942, and thus meet the requirements for use in concrete.

|

Appearance

|

short fibrous

|

PH value

|

7.0±1.0

|

|

Dispersity

|

wonderful

|

Water obsorption

|

≥8.8 times weight of filter aid

|

|

Average length

|

200-1000μm

|

Moisture content

|

≤5%

|

|

Color

|

white

|

Thermal resistance

|

230℃

|

1. LVJIAN® TM300 : suitable for filtering plates and cakes.

2. LVJIAN® TM800 : suitable for decorative paint and self-leveling cement, gypsum products, cement binders and coatings.

3. LVJIAN® FM200 : suitable for sealing adhesive, caulking agent and ceramic tile adhesive, emulsion paint and dry powder paint.

4. LVJIAN® FM300 : suitable for inner and outer wall putty, tile binder, decorative mortar, adhesive mortar and gypsum binder.

5. LVJIAN® FM500 : suitable for inner and outer wall putty, tile adhesive and thermal insulation mortar.

About us

1, the company professional to do cellulose fiber

Equipment & technology

2, the quality of cellulose fiber and production is the biggest supplier in

Service

3, stable product quality , supply, the good faith management

Our Company

Wuxi green construction technology co., LTD was established in 2003. Through more than ten years of scientific research and development, the company has been developing rapidly.The company's products cover advanced fields such as building materials, machinery, machine manufacturing, power equipment manufacturing, chemical engineering, medical intermediates and plastics.

We mainly produce cellulose fiber, polypropylene fiber and paper cat litter.Cellulose fiber is widely used in filter material industry, seal material industry, construction concrete mortar industry, road asphalt industry, friction material industry and so on.Polypropylene fiber is widely used in construction concrete and mortar.Paper cat litter is a new kind of eco-friendly pet product for pet.Our products are sold all over the country and exported to Europe, America and southeast Asia.

Our Exhibition

Our survice.

We can offer small bags or ton bags

We are glad to offer you 0.5kg or 1kg free sample for

testing

100% natual eco-friendly paper cat litter

Mid. Order: 1 Tons more quatities, more cheaper FOB Price: US $ 1180-1240/Ton

Road Construction Cellulose Fiber Pellet for Asphalt Mixtures/SMA

Mid. Order: 1 Tons more quatities, more cheaper FOB Price: US $ 1300-1400/Ton