- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

WUHAN

-

Brand Name:

-

TXT LASER

-

Pulse Width:

-

tunable

-

Wavelength:

-

1064NM

-

Dimensions:

-

110.00cm * 80.00cm * 150.00cm

-

Weight (KG):

-

180 KG

-

Color:

-

Blue White / Red Black

-

Laser Wave Length:

-

1070 Nm

-

Welding Speed Range:

-

0~120 mm/S

-

Welding Thickness Range:

-

0.5-3mm

-

Cooling Type:

-

Water Cooling

Quick Details

-

Max. Output Power:

-

3000W

-

Usage:

-

Mold welding

-

Laser Source Brand:

-

RAYCUS

-

Place of Origin:

-

WUHAN

-

Brand Name:

-

TXT LASER

-

Pulse Width:

-

tunable

-

Wavelength:

-

1064NM

-

Dimensions:

-

110.00cm * 80.00cm * 150.00cm

-

Weight (KG):

-

180 KG

-

Color:

-

Blue White / Red Black

-

Laser Wave Length:

-

1070 Nm

-

Welding Speed Range:

-

0~120 mm/S

-

Welding Thickness Range:

-

0.5-3mm

-

Cooling Type:

-

Water Cooling

Products Description

1) Simple and easy to operate, the weld is not deformed.

2) Laser output is stable, ensuring weld consistency.

3) High power density after laser focusing.

4) The weld seam is smooth and beautiful, the welding workpiece has no deformation, the welding is firm, and no subsequent grinding process is required, which saves time and cost.

5) 360 degree without dead angle micro soldering After the laser beam is focused, a small spot can be obtained, which can be accurately positioned and used in the group welding of micro and small size workpieces for mass production. mainly for the welding of thin-walled materials and precision parts, it can realize spot welding, butt welding, stack welding, sealing welding, etc., high aspect ratio, small weld width, small heat affected zone, small deformation, fast welding speed, no need to be processed after welding or simply processed.

6) Fast, easy to operate, labor saving Fast welding speed, 2-10 times faster than traditional welding, one machine can replace at least 2 welders a year.

7) Long life working, safer and more environmentally friendly laser welding is with low consumables for micro soldering.

2) Laser output is stable, ensuring weld consistency.

3) High power density after laser focusing.

4) The weld seam is smooth and beautiful, the welding workpiece has no deformation, the welding is firm, and no subsequent grinding process is required, which saves time and cost.

5) 360 degree without dead angle micro soldering After the laser beam is focused, a small spot can be obtained, which can be accurately positioned and used in the group welding of micro and small size workpieces for mass production. mainly for the welding of thin-walled materials and precision parts, it can realize spot welding, butt welding, stack welding, sealing welding, etc., high aspect ratio, small weld width, small heat affected zone, small deformation, fast welding speed, no need to be processed after welding or simply processed.

6) Fast, easy to operate, labor saving Fast welding speed, 2-10 times faster than traditional welding, one machine can replace at least 2 welders a year.

7) Long life working, safer and more environmentally friendly laser welding is with low consumables for micro soldering.

Product Paramenters

|

Model

|

TXT-HJ-SC1000

|

TXT-HJ-SC1500

|

TXT-HJ-SC2000

|

||

|

Average output power

|

1000W

|

1500W

|

2000W

|

||

|

Operation Mode

|

CW/Modulate

|

|

|

||

|

Max Modulation Frequency

|

5KHz

|

|

|

||

|

Output Power Stability

|

±3%

|

|

|

||

|

Red Laser

|

Yes

|

|

|

||

|

Terminal Type

|

QBH

|

|

|

||

|

Beam Quality

|

1.3M2

|

1.5M2

|

1.8M2

|

||

|

Polarization

|

Random

|

|

|

||

|

Delivery Cable Length

|

10M

|

|

|

||

|

Power Supply

|

1 PH 220V five wire connect

|

|

|

||

|

Control Mode

|

RS232/AD

|

|

|

||

|

Power Consumption

|

4KW

|

5KW

|

6KW

|

||

|

Cooling

|

Water Cooled

|

|

|

||

|

Operation Temperature

|

10-40 degree

|

|

|

||

|

Max Depth of welding

|

3mm

|

4mm

|

5mm

|

||

|

Machine Weight

|

180Kg

|

200Kg

|

240kg

|

||

|

Package size

|

110CM*80CM*150CM

|

|

|

||

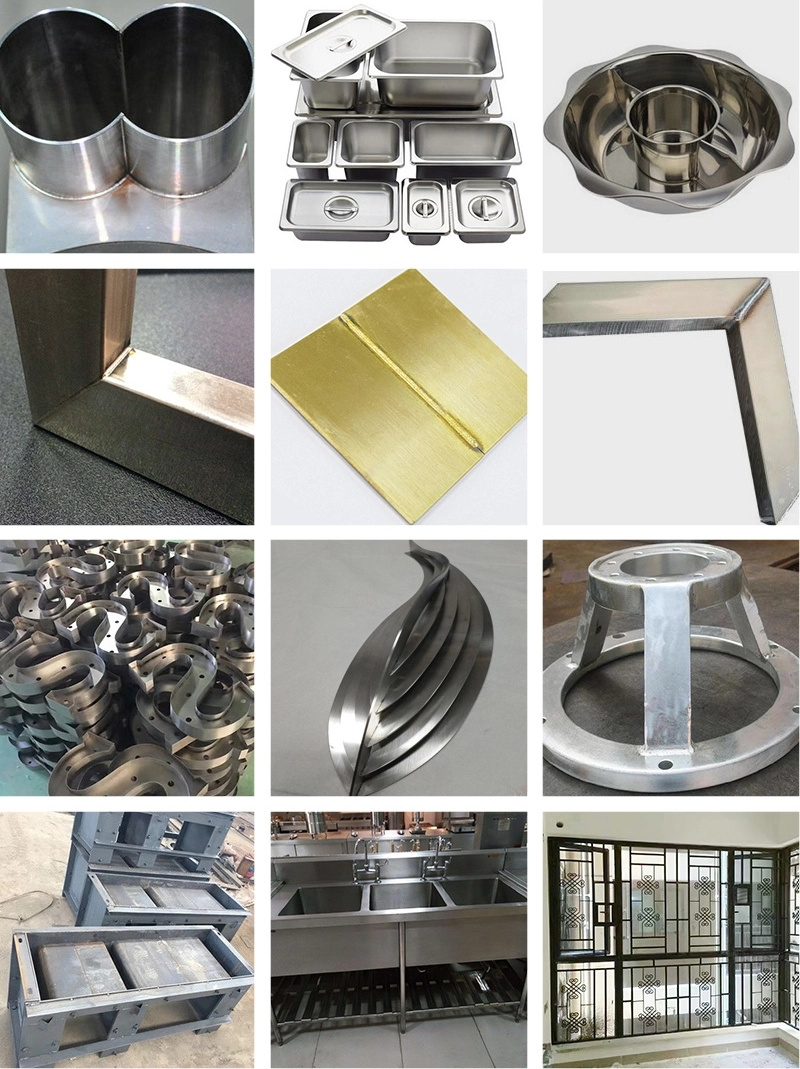

samples

Our Advantages

Wuhan Tianxingtong Optoelectronic Technology Co., Ltd. is a technology enterprise committed to the research and development, production and sales of laser equipment and automation equipment. The company is located in Xinte Optoelectronic Industrial Park, Jiangxia District, Wuhan City. Tianxingtong photoelectric team has more than 20 years of laser industry experience, 18 R & D personnel, equipment annual shipments of 1000+, to provide customers with: free proofing, 8 hours on-site service, 24 hours to help customers solve after-sales problems.

As an industry and trade integrated enterprise, TXT laser adheres to quality as the center, service as the core, and constantly carries out core technology innovation and research and development, and is committed to providing better laser cutting solutions for global customers

Product serialization, diversification, to meet the needs of more customers, excellent product quality and durability, to create maximum value for customers, timely after-sales service, professional and efficient problem solving, free sample cutting, free customer training, mass exhibition support, support OEM,ODM cooperation.

FAQ

Q: How can I install and debug the machine?

A:We will provide instructions and installation videos with the machine, and provide online guidance from English engineers to ensure that the machine can operate normally, and at the same time, let customers learn how to operate and maintain the machine.

Q:Can I customize the machine according to my requirement? Or OEM?

A:TXT is a research and development manufacturing company, we will provide suitable machines according to the specific needs of customers, and provide OEM services.

Q:Can you arrange transportation for me?

A:Of course, for foreign trade business, we provide EXW, FOB and CIF services. Customers with urgent needs can also choose air freight.

Q:What is the warranty period of the machine?

A:According to different types of machines, we provide a two-year or three-year warranty period. During the warranty period, free repairs or replacement of broken parts are provided. Free maintenance services and machine upgrade services are provided for life outside the warranty period.

Q:What's the consumables of the machine? How much?

A:The machine is very easy to maintenance, only lens and laser tube, power supply are consumables. And laser tube lifetime about 10000 hours, as to lens and power supply, they will not damage if no accident.

A:We will provide instructions and installation videos with the machine, and provide online guidance from English engineers to ensure that the machine can operate normally, and at the same time, let customers learn how to operate and maintain the machine.

Q:Can I customize the machine according to my requirement? Or OEM?

A:TXT is a research and development manufacturing company, we will provide suitable machines according to the specific needs of customers, and provide OEM services.

Q:Can you arrange transportation for me?

A:Of course, for foreign trade business, we provide EXW, FOB and CIF services. Customers with urgent needs can also choose air freight.

Q:What is the warranty period of the machine?

A:According to different types of machines, we provide a two-year or three-year warranty period. During the warranty period, free repairs or replacement of broken parts are provided. Free maintenance services and machine upgrade services are provided for life outside the warranty period.

Q:What's the consumables of the machine? How much?

A:The machine is very easy to maintenance, only lens and laser tube, power supply are consumables. And laser tube lifetime about 10000 hours, as to lens and power supply, they will not damage if no accident.

Hot Searches