- Product Details

- {{item.text}}

Quick Details

-

Cooling Capacity:

-

100ton

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

INEO

-

Voltage:

-

380V/50Hz/3Phase

-

Power:

-

According to the situation on site

-

Dimension(L*W*H):

-

Customize

-

Weight:

-

300 KG

-

Core Components:

-

compress machine

-

Feature:

-

other

-

Cooling approach::

-

Water cooled or air cooled

-

Refrigerating unit::

-

Bitzer , copeland compressor,evaporator ,condenser

-

Usage::

-

Meat And Fish Frozen

-

Door type::

-

Customer choice

-

After-sales Service Provided::

-

Field installation, commissioning and training

-

Certification::

-

CE,ISO9001,SASO

-

Functions::

-

Fresh Preservation

-

Temperature range::

-

-20~-18 Celsius

-

Thickness of panel::

-

150 mm

-

After Warranty Service::

-

Online support

Quick Details

-

Temperature:

-

-20~-18 Celsius

-

Compressor brand:

-

Sanyo

-

Panel Thickness:

-

100mm

-

Cooling Capacity:

-

100ton

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

INEO

-

Voltage:

-

380V/50Hz/3Phase

-

Power:

-

According to the situation on site

-

Dimension(L*W*H):

-

Customize

-

Weight:

-

300 KG

-

Core Components:

-

compress machine

-

Feature:

-

other

-

Cooling approach::

-

Water cooled or air cooled

-

Refrigerating unit::

-

Bitzer , copeland compressor,evaporator ,condenser

-

Usage::

-

Meat And Fish Frozen

-

Door type::

-

Customer choice

-

After-sales Service Provided::

-

Field installation, commissioning and training

-

Certification::

-

CE,ISO9001,SASO

-

Functions::

-

Fresh Preservation

-

Temperature range::

-

-20~-18 Celsius

-

Thickness of panel::

-

150 mm

-

After Warranty Service::

-

Online support

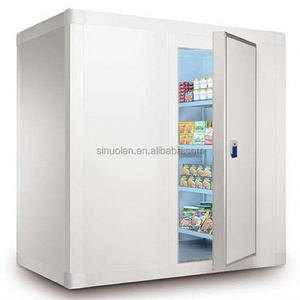

Custom Big Size Vegetable Refrigerator Fruit Storage Freezer Commercial Refrigerator Cold Room Equipment

Custom Big Size Vegetable Refrigerator Fruit Storage Freezer Commercial Refrigerator Cold Room Equipment

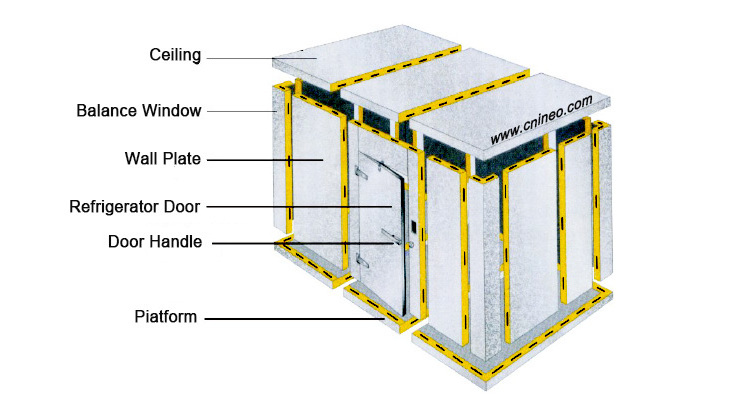

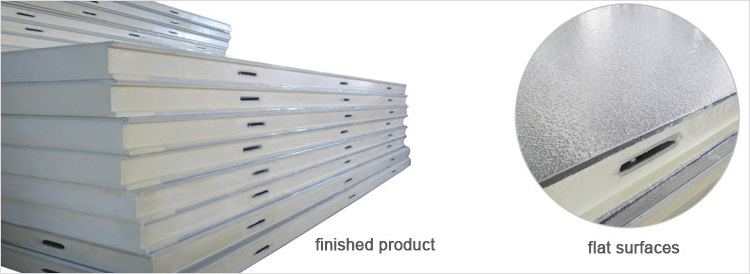

Cold storage board structure characteristics:

Combination cold storage was assembled by PU panels, Cold storage board uses the lock hook link, set up the refrigerator can be combined flexible and convenient. Production mold is designed by adopting special prefabrication, standard width have some specifications 295 mm,590 mm,885 mm,960 mm,1180mm.

Panels with design configuration sealant, ensure that coldstorage leakage in the cold and damp proof, make refrigerator plate appearance more beautiful and easy, to avoid the library board due to hit the glass glue seal between the dismantling of the inconvenience.

Panels adopts full galvanized anti-rust metal between eccentric locking hook, become an organic whole repeatedly make the library structure, more closely with strong, cold storage at the same time has good air tightness and heat insulation effect, is easy to tear open outfit, flexible movement, etc.

Panels was connected by the type of eccentric locks with better air tightness close and better insulation effect, has the disassembling easiliy, can be flexible mobile etc. Such kind of cold storge can be assembled to be different size and capacity on different place.

Cold storage board features:

Cold storage plate in the middle of the heat preservation material adopts polyurethane hard foam, it is the lowest in building material coefficient of thermal conductivity, thermal insulation performance of the best products.

Through the closed bubble formed in the forming process of pore structure, can effectively block the water vapor permeability, bibulous rate is extremely low, thus exerting excellent insulation performance, products are widely used in logistics, warehousing, hotel food and beverage, food processing, environmenta testing and other various industries and fields.

| Feature ltem | Unit | Technique Requirement | Test Result |

| Average Density | Kg/m 3 | 40±2 | 40 |

| Heat Conductivity | W/m.k | ≤0.024 | ≤0.021 |

| Compressive Strength | Kpa | ≥160 | ≥171 |

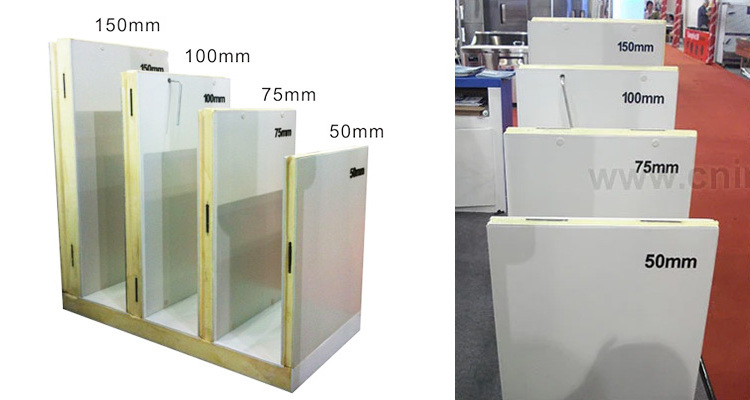

Cold storage board standard:

According to the requirements of use of thermal insulation and cold storage board place is different, can choose different size and the thickness of the material according to the requirements of library board products.

Usually there are four refrigerator plate thickness specification, and make some cold storage plate height and width is according to the size of the scene of the customer or the customer specific requirements for customization.

1)Size standard contrast as follows:

| No. | Surface material | Material Thickness | The Thickness Of The Product | ||||

| 1 | Painted galvanized steel |

0.326,0.376,0.426,

0.476,0.5,0.7,0.8 |

50 | 60 | 75 | 100 | 150 |

| 2 | Stainless steel | 0.5,0.6,0.8-1.5 | O | O | O | O | O |

| 3 | Stucco embossed aluminium | 0.6,0.8 | O | O | O | O | O |

| 4 | PVF steel | 0.6,0.8 | O | O | O | O | O |

| 5 | Written plank combination | Customer choice | O | O | O | O | O |

| 6 | Pu panel | --- | O | O | O | O | O |

2)Using the selection criteria:

| No. | Base plate thinckness | Library inside and outside temperature | Applicable temperature range | Base plate height | The length of the roof |

| 1 | 50 | 30 |

High temperature (5 ℃ or above) |

≤3000 | ≤2300 |

| 2 | 60 | 35 |

High temperature (5 ℃ or above) |

≤3000 | ≤ 2 3 00 |

| 3 | 75 | 40 |

medium temperature (-5℃ or above) |

≤4000 | ≤3000 |

| 4 | 100 | 50 |

Low temperature (-30℃ or above) |

≤6300 | ≤45 00 |

| 5 | 150 | 70 |

UItra Low temperature (-45℃ or above) |

≤10000 | ≤ 60 00 |

Remark: Special circumstances can be customized according tocustomer's request,when installation should be according to the actual situation

configuration walls strengthening beam or hanger steel roof.

Note:

1, Hotel kitchen and restaurant chain of high and low temperature cold storage, the proposal USES 100 mm thick plate refrigerator.

2, below-30℃ low temperature cold storage, recommended 150 mm thick plate refrigerator.

1.Cold Storage Panel:

The structure characteristics of cold storage panel

Adopt new automatic molding equipment, single template using a 50 mm thick steel plate, internal potential temperature control system is equipped with a cold, keep the panel in the process of forming the best molding temperature, to ensure that the library board face level off after the plate shape.

1)Eccentric device for the cam lock, cam particularly on processing, simple to use convenient.

2)That between of the cam lock outside and PU panel Interface of flanging process, make the lock hook and PU closer connection.

3)Cold storage panel adopts special mould, through high pressure foaming and molding, board with board between structure closely, with sealing gasket.

2.Different material panel:

| No. | Material | Material characteristics | Applied range | Material thickness |

| 1 | Stainless steel | Use 304# steel,with good corrosion resistance and heat resistance, low temperature strength and good mechanical properties such as resistance to bending,non-magnetic | Applicable to high-end hotels and seafood, such as cold storage. | 0.5mm~1.5mm |

| 2 | PVF steel | PVF steel was made by thin steel, the surface composite light or inferior smooth PVC film of a metal composite panels. | Applicable to acid cold storage,such as:seafood frozen trunk Marine refrigerated container etc | 0.6mm&0.8mm |

| 3 | Stucco embossed aluminium | Used the mold to make the flat aluminum plate extrusion grain. | Applicable to indoor hotel/kitchen refrigerator. | 0.6mm&0.8mm |

| 4 | Painted galvanized steel | Hot galvanized or hot dip aluminum zinc plate as substrate, the lacquer that bake again. |

Applicable to the logistics/food/hotel/warehousing

and cold storage |

0.326mm~0.8mm |

| 5 | Galvanized steel | In the manufacture of 80-125 grams of zinc on the surface plating layer, after heat treatment after forming,strong corrosion resistance. | Applicable to cold storage bedplate | 0.5mm~1.5mm |

| 6 | Non-slip aluminum plate | Made of aluminum alloy materials after surface processing extrusion molding, non-slip LiuYeXing decorative pattern,hardness high corrosion resistance. | Applicable to the personnel frequent trample, not lay cement tile floor | 1.5mm~5.0mm |

Note:

According to the different requirements of customers, refrigerator production use different material combination.(specific can see the table below)

The cold storage floor interior surface and buried steel or wood square, reinforcement, so as to adapt to replenish onr's stock in the heavy truck driving or bear the weight of the shelf.

Some cold storage directly using strip PU do bottom, in its upper berth on a certain thickness of cement to make a floor board, such already strong and durable, suitable for hotel kitchen.

Q1.Can you provide a design solutions?

A: Yes, we can provide free design solutions for various catering projects, such as hotel kitchen, restaurant, bakery,

bar, etc. Please provide us planning area of your project.

Q2.How can I get a quick quote?

A:

Please tell us the product list, seating number of the restaurant, the area of the kitchen and the menu.

Q3. How long is the warranty period?

A:

One year warranty. If there is any problem with the goods during the warranty period, please provide relevant

evidence. We will send you relevant spare parts.

Q4. What is the packing of the goods?

A:

Normally packing is carton/wooden frame or wood case. If there are other requirements, please advise.

Q5.How long is the delivery time?

A:

Generally 7~15 days, actual situation depend on products items and quantity.

Q6.Can you provide customized product?

A:

Some products can be customized, please inform us of your demand.

Q7. If the machine doesn't or I don't know how to operate?

A:

We will provide product's instructions in advance.Besides, our professional technicians who can answer

your questions and provide operation video if necessary.

Q8. How is the transportation?

A:

According to the size of the products, quantity, and the customer's requirements, transporting products

by express, by air or by sea.

Q9. Can we arrange door-to-door service?

A:

Some countries and regions can arrange door-to-door service. Please provide your detailed address.

Q10. Can you help me to drop-shipping?

A:

Yes, we will collect corresponding charge, specific charge detail please consult with us.

Q11. Whether the product is English panel and manual?

A:

Yes, we will offer English version products normally.

Q12. Voltage and plug of the product?

A:

Our company offer conventional plug and voltage, please advise us your demand when you ordering.

Q14. Payment term?

A:

30% deposit before production, 70% deposit before delivery.