metal tile substrate. The fuselage design adopts a three-beam four-column structure. The equipment is composed of a fuselage, an

oil cylinder, a stroke limit device, and a mold. The structure is simple, economical and practical.

|

Main specifications of the production line

|

|

|

|

Production speed

|

4000-7000pcs/day

|

|

|

Machine weight

|

About 35MT

|

|

|

Total installed capacity

|

200 kw,AC

3

80V 50 HZ

|

|

|

Suitable material

|

Coil material color steel sheets, galvanized plates,galvalume plates

|

|

|

Steel plate thickness

|

0.32-0.5mm

|

|

|

Steel plate width

|

1000mm-1450mm as per the profile drawing

|

|

|

Product condition

|

Plant area 2000 square mcters(25meters*80meters),Mainframe product environment temperature above 20°C

|

|

|

Production line characteristics

|

Horizontal, continuous product, stepless frequency conversion variable speeds,PLC control, having reliable performances, easy operation.

|

|

|

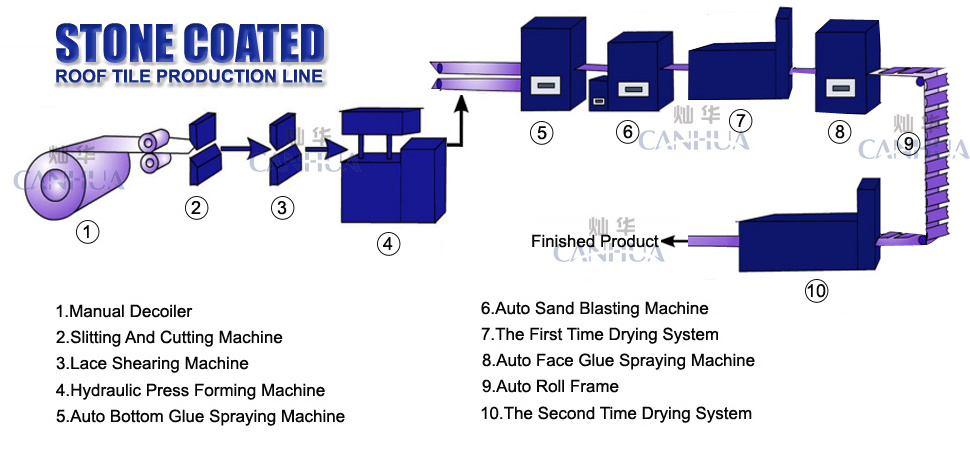

Components of the whole production line

|

|

|

||

|

|

Manual decoiler

|

1 set

|

||

|

|

Slitting and cutting machine

|

1 set

|

||

|

|

Lace Shearing Machine

|

1 set

|

||

|

|

Hydraulic pressing machine

|

1 set

|

||

|

|

Auto bottom glue spraying section

|

1 set

|

||

|

|

Auto stone coated section

|

1 set

|

||

|

|

The first time drying section

|

1 set

|

||

|

|

Auto face glue spraying section

|

1 set

|

||

|

|

The second time drying section

|

1 set

|

||

|

Accessories making machine

(Ridge tile production line)

|

Punching machine

|

1 set

|

||

|

|

Rolling machine

|

1 set

|

||