- Product Details

- {{item.text}}

Quick Details

-

Air Pressure(MPa):

-

0.8 MPa

-

Sheet Thickness(mm):

-

0.2 - 2 mm

-

Heating Power (kW):

-

140 kW

-

Air Comsumption(L/min):

-

3000 L/min

-

Water Comsumption(L/min):

-

10 L/min

-

Place of Origin:

-

Guangdong, China

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

L10000*W2500*H2800mm

-

Weight (T):

-

10 T

-

Forming Area:

-

750*610mm

-

Material:

-

PET PLA PS PP PVC etc

-

Speed:

-

40cycle/min

-

PLC:

-

Delta

-

Keyword:

-

thermoforming machine

-

Forming Depth:

-

120mm

-

Finished Products:

-

food containers

-

Certification:

-

ce

-

After Warranty Service:

-

Field maintenance and repair service

-

Local Service Location:

-

Viet Nam

Quick Details

-

Max.Forming Height(mm):

-

120 mm

-

Forming Width (mm):

-

610 mm

-

Forming Length (mm):

-

750 mm

-

Air Pressure(MPa):

-

0.8 MPa

-

Sheet Thickness(mm):

-

0.2 - 2 mm

-

Heating Power (kW):

-

140 kW

-

Air Comsumption(L/min):

-

3000 L/min

-

Water Comsumption(L/min):

-

10 L/min

-

Place of Origin:

-

Guangdong, China

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

L10000*W2500*H2800mm

-

Weight (T):

-

10 T

-

Forming Area:

-

750*610mm

-

Material:

-

PET PLA PS PP PVC etc

-

Speed:

-

40cycle/min

-

PLC:

-

Delta

-

Keyword:

-

thermoforming machine

-

Forming Depth:

-

120mm

-

Finished Products:

-

food containers

-

Certification:

-

ce

-

After Warranty Service:

-

Field maintenance and repair service

-

Local Service Location:

-

Viet Nam

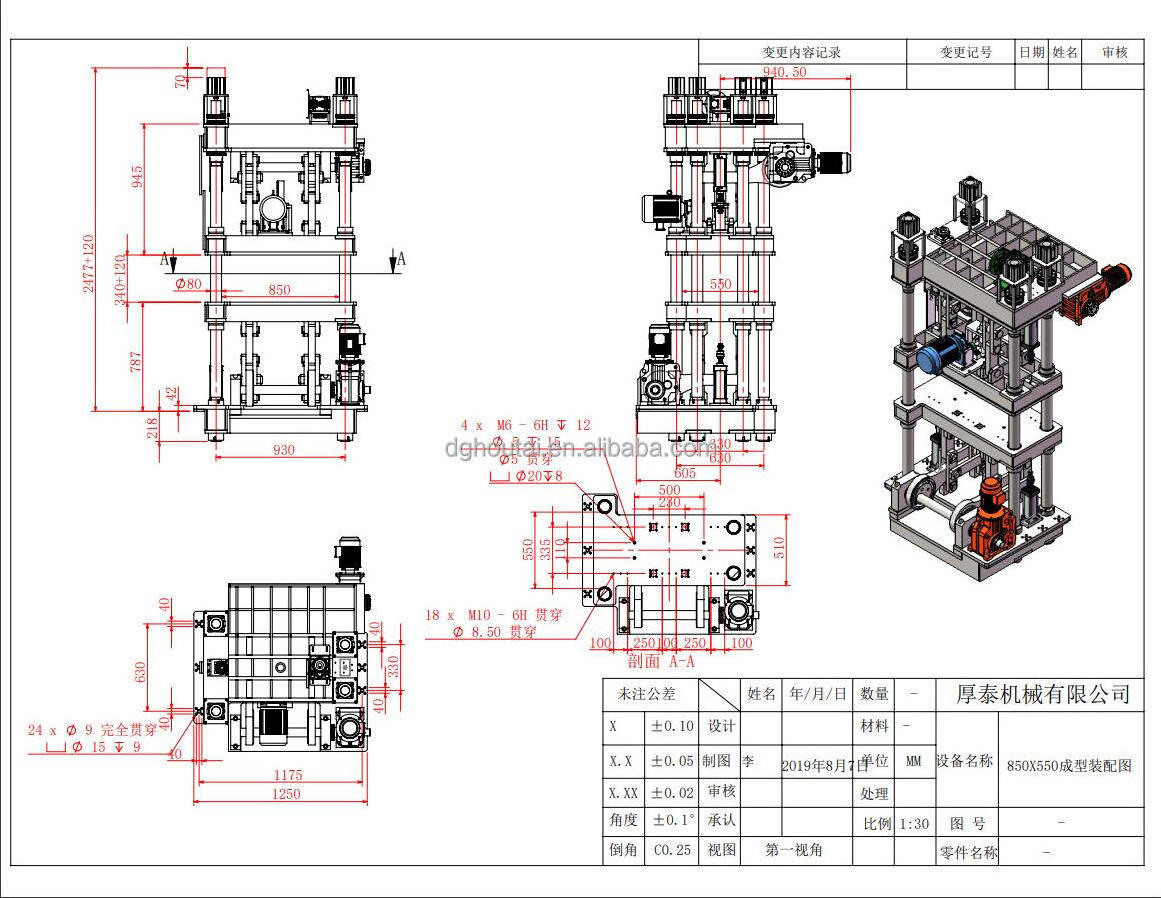

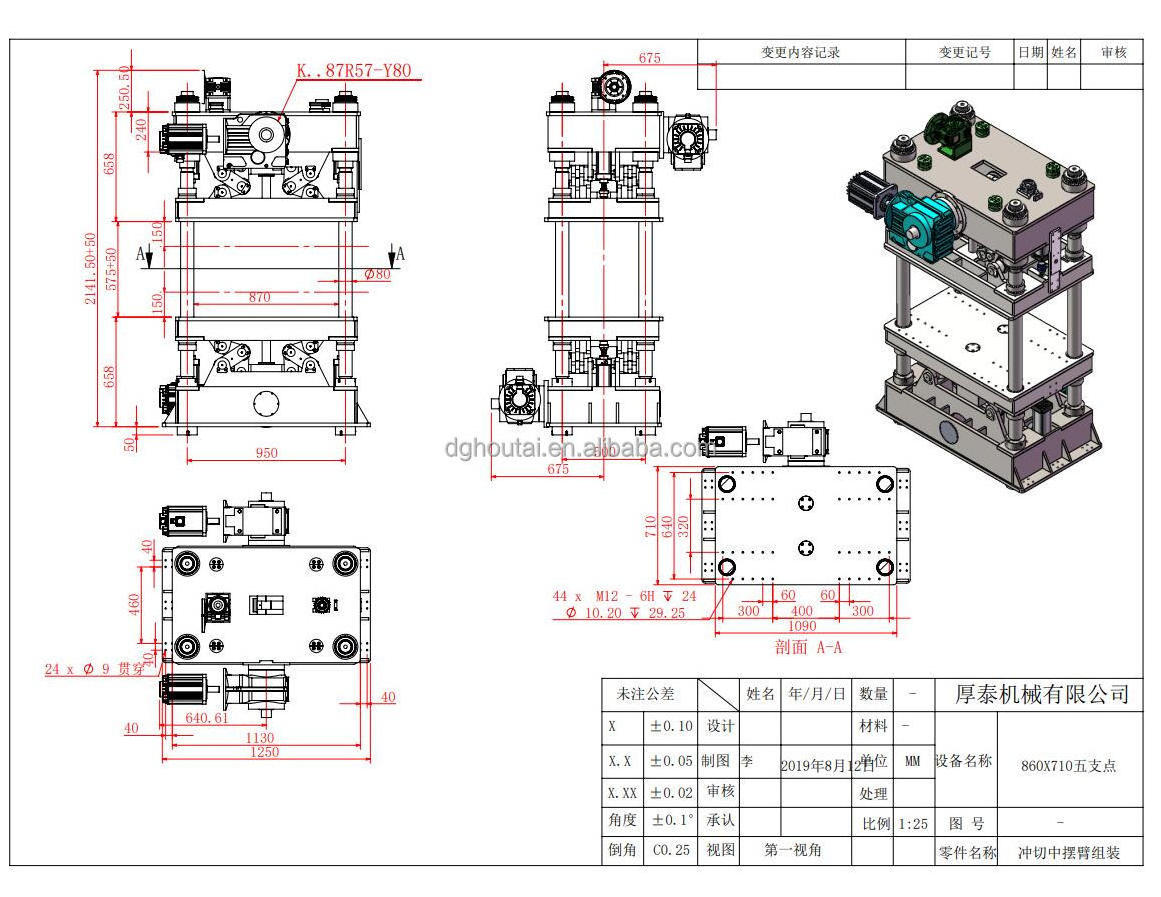

I. Equipment overview

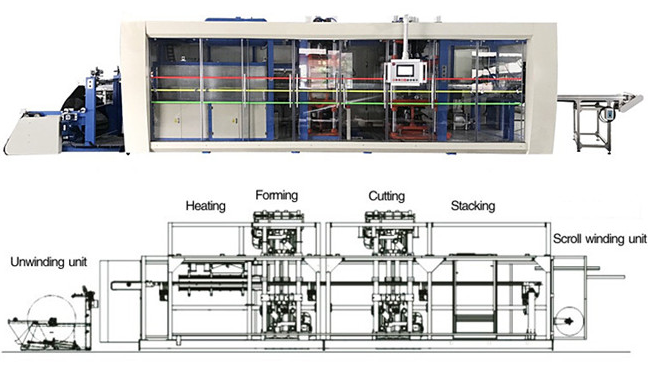

A. Features: New high-efficiency program-controlled plastic positive and negative air pressure thermoforming machine, applying the latest international plastic sheet forming technology, is the integrated design of machine, electricity and gas, using microcomputer and industrial programmable PLC control, the whole system HMI(man-machine).Square tunnel type inlet radiation heater, concave and convex mold can be formed, laser blade punching, its technological process: heating, forming, punching, stacking counting and other main multi-station production line. The production line can be synchronous running at the same time, using the current abroad combined with the domestic advanced molding technology, save labor, prevent secondary pollution, save materials, improve product quality and product percent of pass, exponentially increase the production efficiency, convenient operation, good reliability, functional, high degree of automation, automatic thermoforming and products dedicated to sheet cutting one of the automatic production line.

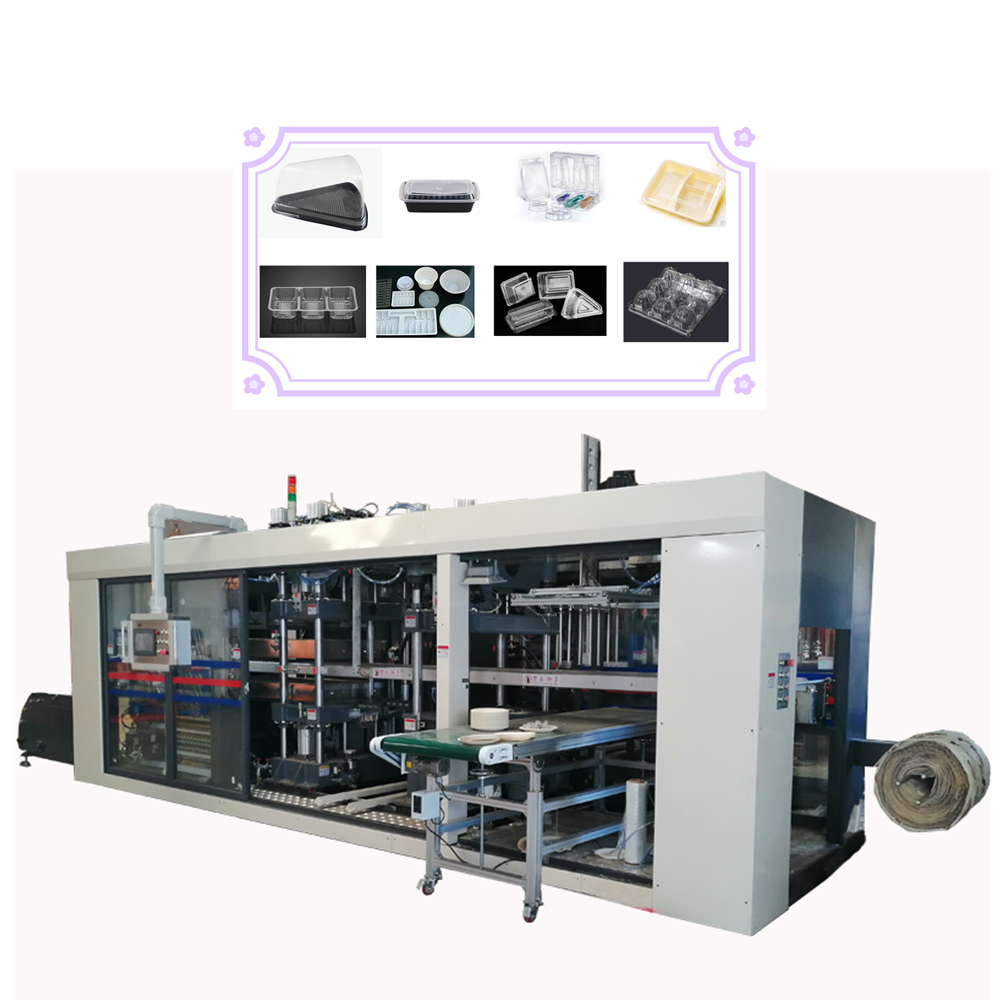

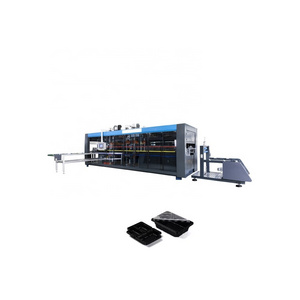

B. Application: Suitable for HPS, PS, PP, PVC, PET, chemical plastic materials such as plastic molding, machining high transparent, high tensile, shallow drawing, circular, square, irregular, two-way stretch up and down, flanging, and other products, the production of various box, dish, tray, bowl, cover, industrial packaging, food packaging, cosmetic packaging and other packaging plastic products.

II. Equipment process flow

Feed sheet → transfer sheet → first heating → second heating → third heating → forming and cooling→ cutting → stacking → scrap rewinding.

Machine Deatils:

| 1 | Clam shell fast food container making machine | https://youtu.be/RqPGYOTw6tY |

| 2 | Automatic blister die cutting machine with robot arm picking | https://youtu.be/_WhOZBWIUv8 |

| 3 | Single side feeding die cutting machine | https://youtu.be/1L7mSXpHsuA |

| 4 | High speed plastic vacuum forming machine | https://youtu.be/s2_kVuoGySs |

| 5 | Disposable cup making machine | https://youtu.be/Ob9hagmtigk |

| 6 | High speed Hydraulic Plastic disposable container Cutting Machine | https://youtu.be/ic8GI8cPv0o |

| 7 | Continuous blister cutting machine | https://youtu.be/CWlSYmM550U |

| 8 | Automatic EPE packaging die cutting machine, multiple rolls cutting | https://youtu.be/bCj977Z3YpU |

| 9 | Vertical foam cutting machine | https://youtube.com/shorts/cGIeeM1roDY?feature=share |

| 10 | Manual feeding hydraulic die cutting machine | https://youtu.be/cfiiAVo2g4U |