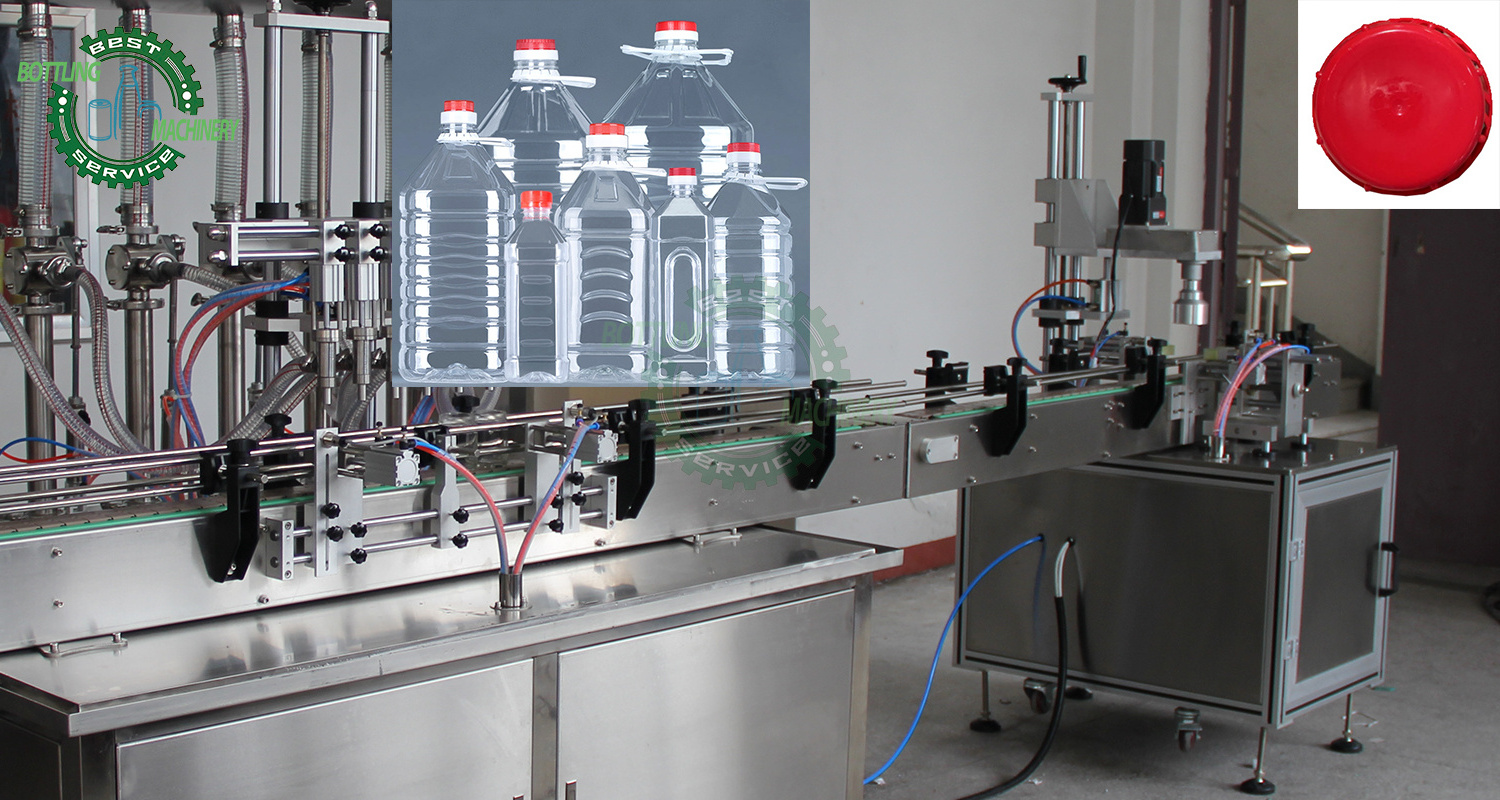

1.The machine is mainly composed of bottle conveying mechanism, cap sorting and feeding mechanism,clamp bottle conveying mechanism,rubbed cap mechanism, and electronic control system. High degree of automation reasonable design, compact structure, easy operation;

2.Capping mechanism spacing, height can be quickly adjusted different specifications of the bottle

and cap;

3.The cover feeding mechanism is equipped with a photoelectric sensing safety protection device, which can control the bottle handling mechanism to realize the self-protection function of "start machine without cover to feeding, and stop feeding when caps are full," to enhance the stability and reliability of the equipment.

Suit for trigger caps, pump caps and sprayer caps.

1) widely used in many industry, such as, cosmetics,food,medicine etc

2) The machine can be suitable for sprayer caps, pump caps and trigger caps.

3) If you have trigger caps. Need to load the caps on the caps tracks one by one.

According to cap type, there are two ways to load caps:

1. Chain conveyor cap lifting machine, this method is currently more popular.

2. Vibrating cap sorter: worker manually pour the scattered lids into the disc, the scattered lids will be sorted out and reach the position of the bottle hanging through the cap channel.