- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

7 * 8-1/2''

-

Application:

-

Oilwll Cementing

-

Size:

-

4 1/2 '' - 20 ''

-

Material:

-

Alloy Steel/Aluminum/Zinc

-

Certification:

-

API & ISO

-

Processing Type:

-

Casting

-

Supplier Level:

-

Tier 1 Supplier of SINOPEC

-

Sample:

-

Available

Quick Details

-

Brand Name:

-

ZS

-

Core Components:

-

centralizer

-

Type:

-

Rigid Casing Centralizer, Soilid Body Casing Centralizer

-

Model Number:

-

7 * 8-1/2''

-

Application:

-

Oilwll Cementing

-

Size:

-

4 1/2 '' - 20 ''

-

Material:

-

Alloy Steel/Aluminum/Zinc

-

Certification:

-

API & ISO

-

Processing Type:

-

Casting

-

Supplier Level:

-

Tier 1 Supplier of SINOPEC

-

Sample:

-

Available

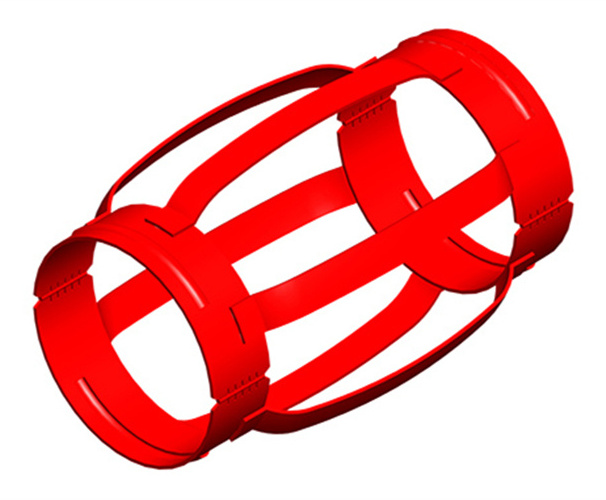

Cast Steel Centralizer for Casing Pipe

Cast Steel Centralizer for Casing Pipe

•Casing centralizer is a cementing tool which applied to centralize casing to improving the cementing quality.

•They are designed for High Restoring Force and Low Starting Force for centralizing the casing pipe in a Horizontal and Deviated well.

•This slip-on centralizer features a long Aluminum collar with spiraled bars to assist in either clockwise or counter-clockwise pipe rotation and to create turbulence in the annulus. It is normally run between two stop collars to provide the casing a smooth bearing surface and reduced torque.

Cast Centralizer Steel Centralizer for Casing Pipe

1.Available in sizes 4-1/2" to 20".

2.Casted steel/aluminum/composite polyer centralizer.

3.Good corrosion resistance .

4.Reducing drag force.

| NO. |

Size (in) |

Inside Diameter (mm) |

Height (mm) |

Total height (mm) |

MAX Diameter (mm) |

| 1 | 5“*12-1/4” | 128-131 | 105 | 690 | 330 |

| 2 | 5”*20” | 128-131 | 105 | 720 | 535 |

| 3 | 5-1/2”*7” | 142-148 | 55 | 650 | 215 |

| 4 | 5-1/2”*8-1/2” | 142-148 | 55 | 650 | 225 |

| 5 | 6”*8-1/2” | 156-158 | 55 | 650 | 235 |

| 6 | 7”*8-1/2” | 181-186 | 55 | 650 | 235 |

| 7 | 7”*9-5/8” | 181-186 | 55 | 650 | 255 |

| 8 | 7-5/8”*9-5/8” | 197-201 | 55 | 650 | 275 |

| 9 | 9-5/8”*12-1/4” | 250-255 | 55 | 650 | 330 |

| 10 | 13-3/8”*17-1/2” | 342-347 | 55 | 650 | 450 |

| 11 | 5-1/2”*8-1/2” | 142-148 | 110 | 650 | 225 |

| 12 | 7”*9-5/8” | 181-186 | 110 | 650 | 255 |

|

13 |

7”*8-1/2” | 181-186 | 110 | 650 | 235 |

| 14 | 5”*6-1/2” | 128-131 | 110 | 650 | 175 |

| 15 | 7-5/8”*9-1/2” | 196-200 | 110 | 650 | 250 |

| 16 | 10-3/4”*12-1/4” | 274-276 | 110 | 650 | 330 |

| 17 | 5”*6-1/4” | 130-132 | 110 | 650 | 170 |

| 18 | 9-5/8”*12-1/4” | 250-255 | 110 | 650 | 330 |

| 19 | 9-5/8”*12-1/4” | 342-347 | 110 | 650 | 450 |

| 20 | 5-1/2”*8-1/2” | 142-148 | 55 | 650 | 225 |

API 10D

ISO 14001 ISO 9001