- Product Details

- {{item.text}}

Quick Details

-

Worktable Length:

-

5200MM-5600MM

-

Worktable Width:

-

2140MM

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

UNILINER

-

Model Number:

-

UL-199E

-

Warranty:

-

12 Months

-

Color:

-

Customised

-

Certification:

-

CE Approved

-

Using range:

-

4S Station/garage Store/according

-

Company history:

-

13 Years Producing Experience

-

Payment:

-

30% Deposit

-

Air Supply Required:

-

0.8 Mpa

-

Delivery Time:

-

25 Working Days

Quick Details

-

Weight:

-

2500kg

-

Bench Height:

-

520MM

-

Max. Lifting Capacity:

-

3500KG

-

Worktable Length:

-

5200MM-5600MM

-

Worktable Width:

-

2140MM

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

UNILINER

-

Model Number:

-

UL-199E

-

Warranty:

-

12 Months

-

Color:

-

Customised

-

Certification:

-

CE Approved

-

Using range:

-

4S Station/garage Store/according

-

Company history:

-

13 Years Producing Experience

-

Payment:

-

30% Deposit

-

Air Supply Required:

-

0.8 Mpa

-

Delivery Time:

-

25 Working Days

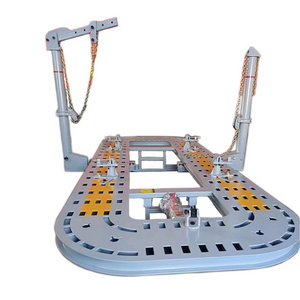

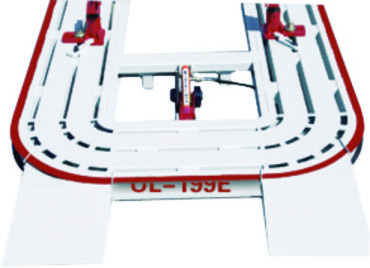

Products Description

UL-199E, full automatic computerized working platform made of rectangular tube steels is designed professionally for body collision repair by choosing better material, improving welding technique and enhancing stress intensity to make the repairing work more precise and faster. One of important features is no-blind working range, which is in accord with the technician's habit to make more convenient operation. It can be widely used for nearly all kinds of imported cars, commercial vehicles and SUVs collision repair.

|

FRAME LENGTH 5200MM

|

|

FRAME WIDTH 2140MM

|

|

FRAME HEIGHT 520MM

|

|

MAX PUSH POWER OF PULLING TOWER 100KN

|

|

RATED VOLTAGE 220/380V

|

|

WORKING RANGE OF PULLING TOWER 360°

|

|

MAX LOAD BEARING 3500KG

|

Detailed Images

Platform

The platform is made of 6mm thickness of rectangular tube, welded by full board with multi-positioning holes surrounded, which ensures the platform with high flatness, strong anti-torsion strength, no-blind fixing ways and efficient straightening.

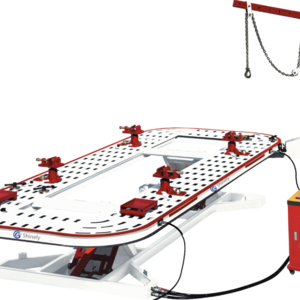

Hydraulic cylinder

Tilt hydraulic lifting platform makes the accidental vehicle loading and unloading more conveniently (even drive the car onto the platform directly).

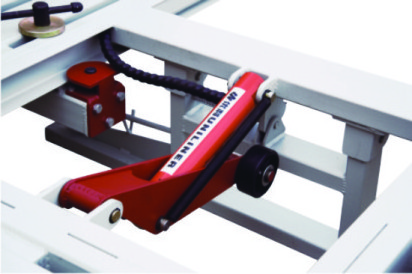

Main clamp

Unique design of spiral movements for main clamps is easier to make jaws upper and lower on precondition of maintaining the flat level by adjusting the pole vertically to clamp different height chassis of all kinds of vehicles. Quick fixed clamp jaws by screwing the shaft clockwise, making chassis clamping more efficient.

Pulling tower

Towers can be rotated 360 degrees along the platform and be made of 10mm seamless steel pipe, diameter of pulling tower tube is 160mm, which means more convenient moving and high intensity if both towers straighten in diagonal line. You only need to move the handle to put the shaft into the hole on the bench to fix the pulling tower

Tool car

All accessories and tools are mechanical streamline design and have durable life by multi-heating and forging processes.

Three important points for heat treatment process to make sure the accessories quality:

Overall forging (mould owned by UNLINER)

Overall conditioning (hardness HRC28 degrees);

High frequency quenching of tooth profile ( hardness HRC40 degrees).

ACCESSORIES

Related Product

About Us

Yantai UNILINER Electromechanical Equipment Manufacturing Co.,ltd is a specialized modern machinery manufacturing enterprise, which is professional at researching, developing and designing Auto Collision Repair Equipments, Auto Measuring and Repairing equipments, and other general machinery equipments.

We have the most professional team to develop, manufacture, sale and service. Many years’ sales experience makes us fully understand customers’ actual demand and products’ performance. We have introduced L-series, U-series and UL-series of 19 models Auto Collision Repair Equipments to the market. Especially we developed the UL-series to complete repairing the large car and luxury imported cars for auto collision repair shops. All of that will bring the most forefront auto repair concept for auto collision repair shops, which will promote the vigorous development for auto collision repair industry.

Customer oriented, technology as support, with solid benefits, to innovation seeks the development of Unisys have full set of machine tools, CNC machine, plasma cutting machine, professional welding equipment, large shot blasting machine and spray painting room, a new addition to the electrostatic spraying line makes the product perfection.

View of Workshop

Certifications

Packing & Delivery

Contact Us

Hot Searches