ZHUONUO WINSKYS TECH CO.LTD

is a professional manufacturer of packaging machine equipment. Our company mainly produces labeling machine,filling machines,etc.The factory own a professional r&d team and after-sales service team. According to the requirement of customer, we

designed the ideal equipment to satisfy customer's demand.Besides, we also provide packaging& Printing products for adhesive labels, paper boxes etc for anyone who needs them.At present, we have install our production in more than 30 countries and regions in the world. WINSKYS would like to move forward together with you and will spare no efforts. Welcome to our company!

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

WINSKYS

-

Dimension(L*W*H):

-

2000*1100*2100

-

Weight:

-

500 KG

-

Name:

-

automatic oil filling machine

-

Function:

-

filling capping labeling date coding

-

Filling material:

-

liquid,oil,essential oil,etc.

-

Usage:

-

food,cosmetic,industry etc

-

Capacity:

-

2000-30000bph

-

Processing Types:

-

Piston Filling,servo motor drive

-

Filling accuracy:

-

≤ ±1%

-

Control:

-

autoamtic PLC control

Quick Details

-

Machinery Capacity:

-

4000BPH, 20000BPH

-

Packaging Material:

-

Plastic, Paper, Metal, Glass, Wood

-

Filling Material:

-

Oil

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

WINSKYS

-

Dimension(L*W*H):

-

2000*1100*2100

-

Weight:

-

500 KG

-

Name:

-

automatic oil filling machine

-

Function:

-

filling capping labeling date coding

-

Filling material:

-

liquid,oil,essential oil,etc.

-

Usage:

-

food,cosmetic,industry etc

-

Capacity:

-

2000-30000bph

-

Processing Types:

-

Piston Filling,servo motor drive

-

Filling accuracy:

-

≤ ±1%

-

Control:

-

autoamtic PLC control

You May Like

Product Paramenters

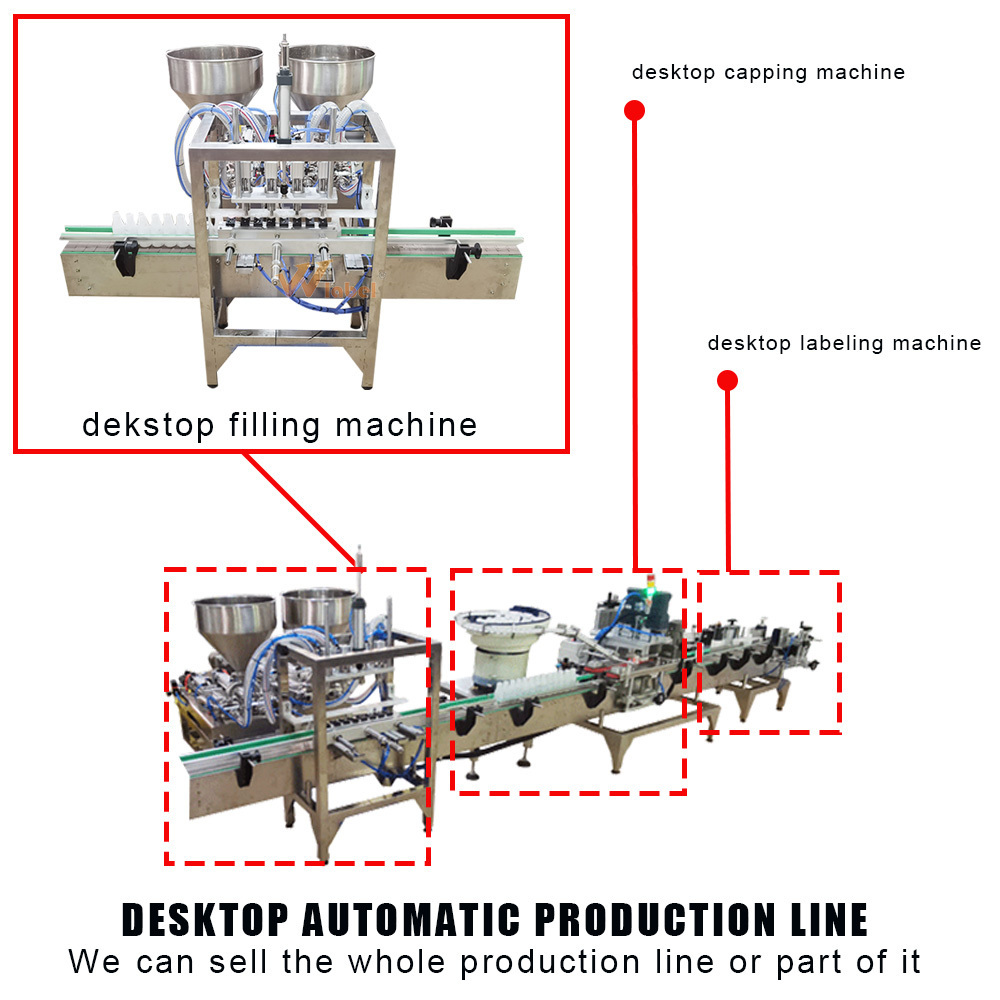

Production Line=Canning system + Lid system+Capping system + Labeling system

This production line is suitable for small scale production,can fill liquid,cap bottles and label stickers automatically.These

desktop type machines can save working space and help you improve working efficiency greatly.It is widely used in

food,beverage,beer,cosmetics,daily chemical and pharmaceutical industries.

If you have other ideas about the machine, please feel free to contact us and we will help you realize it!

|

Machine name

|

Filling machine

|

|

Voltage

|

110V/220V

|

|

Filling nozzles

|

4(we can customize the nozzles based on your demands)

|

|

Working speed

|

20-40 bottles/min(based on bottles and liquids)

|

|

Air pressure

|

0.4MPa

|

|

Filling accuracy

|

≤±1% (For water)

|

|

Diameter of filling nozzle

|

Can be customzied

|

|

Conveyor belt length

|

1m

|

|

Package size

|

About 1185*710*795mm

|

|

Net weight/Gross weight

|

About 70kg/90kg

|

|

Machine name

|

Vibration plate machine

|

|

Speed

|

20-40pcs/min

|

|

Voltage

|

110V/220V

|

|

Air Pressure

|

0.4 MPa

|

|

Capacity

|

100-500pcs caps

|

|

Cap size

|

18-40mm

|

|

Vibration plate size

|

750*650*565mm

|

|

Package size

|

800*700*600mm

|

|

Machine name

|

Capping machine

|

|

Bottle Height

|

Can be customzied

|

|

Bottle Caps Diameter

|

Can be customzied

|

|

Working Speed

|

20-40 bottles/minute (depending on bottle and caps)

|

|

Working Voltage

|

110V/220V

|

|

Working Pressure

|

0.4 MPa

|

|

Conveyor Length

|

1117mm

|

|

Net weight/Gross weight

|

About 70kg/100kg

|

|

Package Size

|

About 1160*610*1140mm

|

|

Machine Size

|

About 1120* 580* 1110mm

|

|

Machine Name

|

Positioning Round Bottle Labeling Machine

|

|

Working Speed

|

About 20-35 pcs/min

|

|

Labeling Precise

|

± 0.5mm

|

|

Suitable Bottle Diameter

|

About 25-100mm

|

|

Suitable Bottle Height

|

About 25-230mm

|

|

Label Width

|

20-100mm

|

|

Label lenght

|

20-320mm

|

|

Air Pressure

|

0.4 MPa

|

|

Power

|

Single Phase 220V

|

|

Machine Size

|

About 1300*900*630mm

|

Why Choose WINSKYS?

|

1.Professional Packaging Equipment Production Experience

|

|

|

|

|

||||

|

1.1

|

Produced according to export standards. The machine has CE and can be exported to Europe

|

|

|

|

||||

|

1.2

|

Our engineers with 20 years of experience can provide cost-effective customized labeling solutions

|

|

|

|

||||

|

2.Have a Professional R & D Team

|

|

|

|

|

||||

|

2.1

|

Research and develop 20-50 labeling machines and filling lines every year

|

|

|

|

||||

|

2.2

|

Accept any customized equipment orders and provide one-to-one OEM solutions and services

|

|

|

|

||||

|

3.Rich Export Experience

|

|

|

|

|

||||

|

3.1

|

Our machines are 100% exported. The US and Canada accounted for 60% and Europe accounted for 30%

|

|

|

|

||||

|

3.2

|

Provide English version of machine operation text documents and videos

|

|

|

|

||||

|

3.3

|

Accept online phone or video communication in English or Thai

|

|

|

|

||||

|

3.4

|

US, Canada and Asian countries can provide on-site after-sales service

|

|

|

|

||||

|

3.5

|

Can provide DDP's sea, rail and air to door services to make customer purchases easier

|

|

|

|

||||

|

3.6

|

Customers in Asian countries provide one-day international express service

|

|

|

|

||||

|

4.WINSKYS Exclusive Services

|

|

|

|

|

||||

|

4.1

|

You can send us your products and labels,we can use the machine to help you label your products

|

|

|

|

||||

|

4.2

|

Provide high-quality label printing

|

|

|

|

||||

|

4.3

|

Free text samples

|

|

|

|

||||

|

4.4

|

There are branches in US and Canada and we ship directly locally. Provide fast delivery and cheap prices

|

|

|

|

||||

Core Components Parts Show

For more machine details pictures or videos,

click contact us to get.

Filling Mechanism

The larger air cylinder is used to control the lifting distance of diving nozzles This kind of filling nozzle is suitable for filling foamy liquid,improves production quality.

Receiver

Made of high-grade stainless steel, it is easy to clean, safe and environmentally friendly.

Capping Mechanism

Designed for various shapes of bottle caps,like smoke oil bottles,spray bottles beverage bottle caps.It will press the bottle caps

and tight it automatically Improve working efficiency greatly.

and tight it automatically Improve working efficiency greatly.

Labeling Mechanism

The product completes the labeling action here

PLC Touch Screen(Panasoic)

Control the speed of the motor, the delay of the cylinder and the photoelectric, etc. The interface supports multiple languages.

Electric Eye(SICK)

Check the label to ensure that the product is accurately labeled

Customer Feedbacks

Wood Packaging

ABOUT US

CE

ISO

PATENT

TEAM

FACTORY

CUSTOMERS

Our machines are only for overseas markets, and we export 30-50 units every month. At present, we have accumulated more than 100 foreign customers. Customers are mainly concentrated in

North America (USA), Europe (UK, Germany, Spain, etc.) and Asia (Thailand, Malaysia, Philippines, Vietnam, etc.)

|

FAQ

|

|

|

|

1.Can your machine meet our need well?

|

Pls supply us your products and label size (the photo of products with label on it is rather helpful), then I will suggest you the suitable machine for reference.

|

|

|

2.How long is the delivery date?

|

We have stock, just one day.

|

|

|

3.What is your terms of payment ?

|

T/Tdeposit.50% deposit and 50% payment to be settled before shipping.via bank account,paypal,western union,alipay,trade assurance.

|

|

|

4.How can you ensure the machine's quality after we put the order?

|

Before the delivery, we will send you machine's pictures and videos, or you can come to us to have the quality checking by yourself, or by the third party inspection organization contacted by your side.

|

|

Hot Searches