- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

refer to capacity

-

Warranty:

-

One Year

-

Weight:

-

refer to capacity

-

Power:

-

1.5KW - 75 KW

-

Certification:

-

CE

-

Raw material:

-

waste tyre, rubber, plastic

-

Heating material:

-

coal ,wood, gas ,oil

-

cooling method:

-

coil pipe or condenser

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

SINODER

-

Model Number:

-

waste tyre pyrolysis equipment

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

refer to capacity

-

Warranty:

-

One Year

-

Weight:

-

refer to capacity

-

Power:

-

1.5KW - 75 KW

-

Certification:

-

CE

-

Raw material:

-

waste tyre, rubber, plastic

-

Heating material:

-

coal ,wood, gas ,oil

-

cooling method:

-

coil pipe or condenser

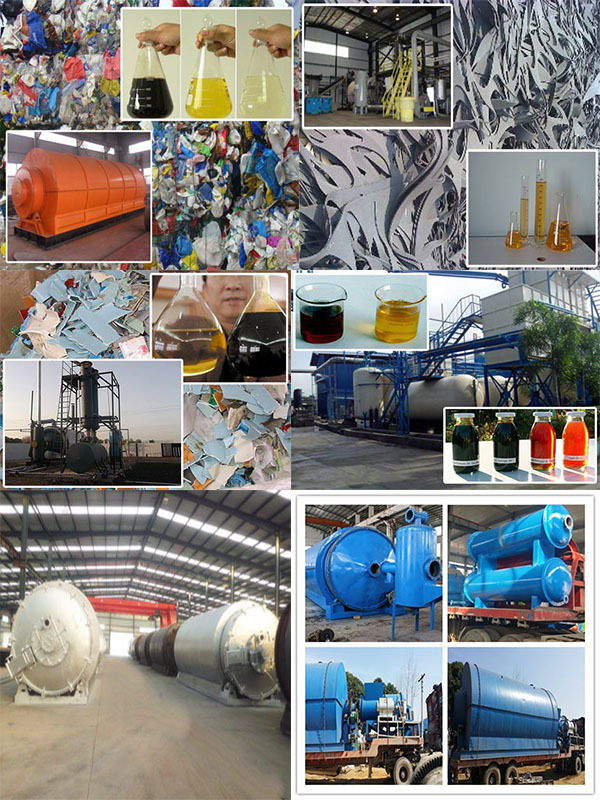

lastese generation waste tyre pyrolysis to oil machine Waste Plastic and Tyre Pyrolysis Plant

Brief introduction of tire pyrolysis machine

Waste tire pyrolysis machine is used for recycling waste tire,rubber,plastic and pyrolyze those waste into reclaimed tyre oil.

After the waste tires being processed by the tire pyrolysis machine,it will come out tire oil(fuel oil) ,carbon black,steel wire.

Tire oil (Fuel oil)

The fuel oil can be sold directly.It can be widely used for Iron and Steel Plant,smelting plant,restaurant,bathing center,etc.

Or combined with our oil distillation machine to further refine the fuel oil,thus you can get national standard diesel and gasoline,it can be used for cars,vessels and create huge profits for you.

Technology : Waste to energy using pyrolysis technology

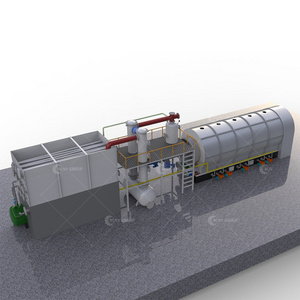

Main process of tire pyrolysis equipment

1.Cut a whole car, bus or truck tire into 7-8 pieces.

2.Feed the furnace with the tire pieces.

3.After the tires are loaded, burn the hearth and start to heat the furnace, then start the power.

4. When the temperature reach 180℃, the oil gas begins to generate, it passes the interface channel and then goes into theatmolysis tower.

5.The heavy and light oil gas are separated in the atmolysis tower, the heavy one precipitate in the bottom, and the light one keeps on moving and going through the catalyst in the headpiece.(the quality of the oil catalyzed by the catalyst is better than the one never been catalyzed).

6. The oil gas catalyzed continues to pass the pipeline, and is turned into liquid fuel oil after the cooling of two condensers.

7. The fuel oil flows into the oil-gas separator,andprecipitate in the bottom. Till the whole process is finished, we collect the oil by the oil-out.

8.HC gas generates while the system generates the oil gas, when the fuel oil remains in the bottom of the separator, it goes on passing the pipeline, and goes into the gasholder finally.

9. One part of the HC gas is leaded on to the hearth and burnt as fuel there; while the other part is burnt in the burner.

10. In addition, the smoke dust produced by burning the fuel goes into the smoke dust processing system forpurification treatment.

The whole system output into the air is only the water steam, so it can not affect environment.

Oil yield for different raw material

|

|

Used tyres,scrap tyres |

Big truck tyres |

45%--50% |

|

Car tyres |

40% |

||

|

Bicycles and motorcycles tyres |

30%--35% |

||

|

Waste plastics |

Fishing net,Safety net, farm-oriented film |

45%--50% |

|

|

Conwenient bags , weave bags |

40% |

||

|

Off –cut of recycled paper mill |

20%--30% |

Final product usage

|

Name |

output |

useage |

|

tyre oil |

45% |

*can be sell directly *can be make diesel and gasoline by using oil distillation machine *can be as fuel |

|

carbon black |

35% |

*can be sell directly *can be made fine carbon by using carbon refining machine. *can be made carbon pellet by using pellet machine. |

|

steel wire |

15% |

*can be sell directly. *can be made steel bloom by using hydraulic press machine. |

|

oil gas |

5% |

*can be as fuel heating machine by using gas burner intead of fuel. *can be storage as fuel for other heating. |