- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Kesu - JSI220912

-

Brand Name:

-

Kesu

-

Product name:

-

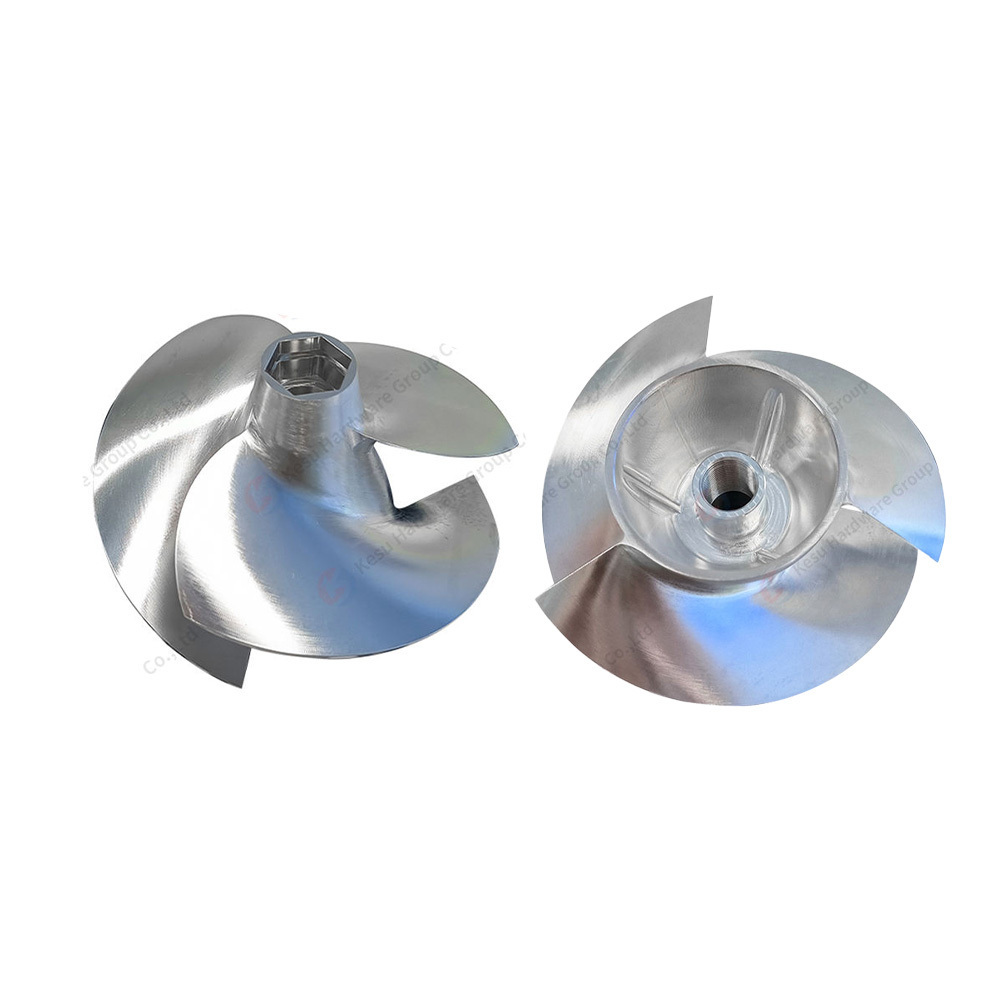

Jet Ski Impeller

-

Process:

-

CNC machining

-

Surface treatment:

-

Customer's Request

-

Material:

-

Customers' Requirement

-

Service:

-

Customized OEM CNC Machining

-

Drawing Format:

-

2D/(PDF/CAD)3D(IGES/STEP)

-

Equipment:

-

3/4/5 Axis Center Machining

-

Tolerance:

-

0.01- +/-0.005mm

-

Logo:

-

Accept Custom Logo

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys, Other

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

Kesu - JSI220912

-

Brand Name:

-

Kesu

-

Product name:

-

Jet Ski Impeller

-

Process:

-

CNC machining

-

Surface treatment:

-

Customer's Request

-

Material:

-

Customers' Requirement

-

Service:

-

Customized OEM CNC Machining

-

Drawing Format:

-

2D/(PDF/CAD)3D(IGES/STEP)

-

Equipment:

-

3/4/5 Axis Center Machining

-

Tolerance:

-

0.01- +/-0.005mm

-

Logo:

-

Accept Custom Logo

Our Services

CNC Precision Machining

Large CNC Machining

Low Volume CNC Machining

High Volume CNC Machining

Multi-Axis Simultaneous Machining

Simultaneous 4-Axis Machining Simultaneous 5-Axis Machining Simultaneous 6-Axis Machining

CNC Turning

Turning Service

CNC

Turn-milling Service

5-Axis Turn-milling

Swiss Machining Service

Metal 3D Printing Service

Aluminium 3D printing

Stainless Steel 3D Printing

Die Steel 3D Printing

Titanium 3D Printing

Rapid Prototyping

Metal Rapid Prototyping

Plastic Rapid Prototyping

Die Casting

Aluminium Die Casting

Zinc Die Casting

Steel Casting

Aluminium Extrusion Profiles

Sheet Metal Fabricating

Laser Cutting

Stamping

Welding

Surface Finishes

Polishing/Grinding/Brushed Finish/Sand blasting/ Painting/ Powder Painting and More

Quality Control

Quality Assurance

At present, Quality assurance team equipped with many advanced testing machinesand many regular testing equipment. Such as the

Coordinate Measuring Machine(CMM),2.5D Measuring Machine, Altimeter, X-ray Fluoresence Spectrometer, Caliper, Micrometer etc

.

About Us

Kesu Hardware Group Co., Ltd

Kesu Hardware Group Co., Ltd have 15+ Years Experience of Precise 4-5-axis CNC Machining Service on big-size, complex, and difficult parts. About 200 machine tools give us great production ability from low-volume to high-volume manufacturing, including swiss-type turning, cnc machining, plastic injection, die casting, 3D printing and vacuum casting etc.

Welcome to get a quote

.

Workshop

CNC Machining center(Milling), CNC Lathe, Grinding machine, Cylindrical grinder machine, Drilling machine, Laser Cutting Machine,etc.

More real shots

Quality Certifications

Kesu's quality management system aims to deliver efficient prototypes and machining services that meet the unique requirements of each customer. Kesu Hardware manufacture in compliance with, among others, the following standards:

Our Partner

Product Cases

Surface Treatment

|

Material Available

|

|

|

|

|

||||

|

Aluminum

|

AL6061, AL6063, AL6082, AL7075, AL5052, A380, etc

|

|

|

|

||||

|

Steel

|

Mild Steel, Carbon Steel, 1018, 1035, 1045, 4140, 4340, 8620, XC38, XC48, E52100, Q235, SKD11, 35MF6Pb, 1214, 1215, etc

|

|

|

|

||||

|

Stainless Steel

|

303, 304, 304L, 316, 316L, 410, 420, 430, etc

|

|

|

|

||||

|

Iron

|

A36,45#, 1213, etc

|

|

|

|

||||

|

Brass

|

HPb63, HPb62, HPb61, HPb59, H59,H68, H80, H90, etc

|

|

|

|

||||

|

Titanium Alloy

|

TC1, TC2, TC3,TC4, etc

|

|

|

|

||||

|

Copper

|

C11000, C12000, C22000, C26000, C28000, C36000

|

|

|

|

||||

|

Plastic

|

ABS, PC, PP, PE, POM, Delrin, Nylon, Teflon, PEEK, PEI, etc

|

|

|

|

||||

|

|

|

|

|

|||||

Why Choose Us

|

Kesu's Machines

|

|

|

|

|||

|

Approximately

100+

machines

give us a strong capability to manufacture from small to large quantities

|

|

|

|

|||

|

Machine

|

Quantity

|

Brand

|

Max Part Size

|

|||

|

3-Axis CNC Machine

|

50

|

|

1500 x 800MM

|

|||

|

4-Axis CNC Machine

|

20

|

AutoCam

|

D600 x L1200MM

|

|||

|

3+2 Axis CNC Machine

|

10

|

AutoCam

|

D500MM

|

|||

|

5-Axis CNC Machine

|

12

|

Jingdiao/DMG/AFMING/Roders

|

D600MM

|

|||

|

6-Axis CNC Machine

|

2

|

DMG Mori

|

D300 x L1200MM

|

|||

|

Lathe Machine

|

2

|

|

|

|||

|

CNC Lathe Machine

|

50

|

Tsugami

|

D300 x L1200MM

|

|||

|

Lathe-Mill Machine

|

10

|

Tsugami

|

D300 x L1200MM

|

|||

|

5-Axis Lathe-Mill Machine

|

1

|

Mazak/DMG Mori

|

D300 x L1200MM

|

|||

|

CNC Swiss Type Automatic Lathe

|

10

|

Tsugami

|

D30 x L500MM

|

|||

|

Metal 3D Printing Equipment

|

1

|

SLM280

|

|

|||

|

Inspection Equipment

|

|

|

|

|||

|

The team is equipped with many advanced testing machines and many conventional testing equipment to ensure that the product qualification rate is above

98%

.

|

|

|

|

|||

|

Equipment

|

Quantity

|

|

Brand

|

|||

|

2.5D

|

3

|

|

|

|||

|

XRF Spectrometer

|

1

|

|

HITACHI

|

|||

|

Altimeter

|

1

|

|

|

|||

|

Calliper

|

20

|

|

|

|||

|

Micrometer

|

10

|

|

|

|||

|

CMM

|

2

|

|

LEAD

|

|||

|

Kesu's Best Tolerance

|

|

|

||

|

|

Tolerance of Metal(mm)

|

Tolerance of Plastic(mm)

|

||

|

Linear Dimensions

|

±0.01

|

±0.05

|

||

|

Diameter

|

±0.002

|

±0.02

|

||

|

Precise Hole

|

±0.002

|

±0.02

|

||

|

Chamfer Heights

|

±0.02

|

±0.05

|

||

|

Angular Dimensions

|

±0º5′

|

±1º

|

||

|

Straightness

|

±0.002

|

±0.02

|

||

|

Flatness

|

±0.002

|

±0.01

|

||

|

Perpendicularity

|

±0.002

|

±0.01

|

||

|

Symmetry

|

±0.002

|

±0.01

|

||

|

concentricity

|

±0.002

|

±0.005

|

||

|

parallelism

|

±0.001

|

±0.01

|

||

FAQ

Q1:

How Can I get a quotation?

A1: Please provide 2D(or 3D) files or samples.Draw format:IGS,STEP,STP, JPEG,PDF,DWG,DXF,CAD etc.

And once we have the required info,you'll get an interactive quote within hours.

A1: Please provide 2D(or 3D) files or samples.Draw format:IGS,STEP,STP, JPEG,PDF,DWG,DXF,CAD etc.

And once we have the required info,you'll get an interactive quote within hours.

If there are problem areas in the submitted design, our quoting engineers provides detailed information on the potential manufacturing issues and suggests possible solutions.

Q2: What is your MOQ?

A2: Do not have MOQ limited, trial order before mass production is welcomed.

Q3: What about quality control?

A3: Self-inspection in every process by the production operator.Spot inspection and final inspection executed by QC, Defective rate be controlled within 1% even lower.

Q4: Can I print my own brand logo on your product?

A4: OEM orders are highly welcome. Please write us the details of your logo, logo position when you send us inquiry.

Q5: Are you manufacturer or trader?

A5:15 Years Experience of Precise 4-,5-axis CNC Machining Service on big-size, complex, and difficult parts. About 100 machine tools give us great advantages from low-volume to high-volume manufacturing. Especially on swiss-type turning, cnc machining.

Q2: What is your MOQ?

A2: Do not have MOQ limited, trial order before mass production is welcomed.

Q3: What about quality control?

A3: Self-inspection in every process by the production operator.Spot inspection and final inspection executed by QC, Defective rate be controlled within 1% even lower.

Q4: Can I print my own brand logo on your product?

A4: OEM orders are highly welcome. Please write us the details of your logo, logo position when you send us inquiry.

Q5: Are you manufacturer or trader?

A5:15 Years Experience of Precise 4-,5-axis CNC Machining Service on big-size, complex, and difficult parts. About 100 machine tools give us great advantages from low-volume to high-volume manufacturing. Especially on swiss-type turning, cnc machining.

Q6:

How do I know my design will be kept confidential?

A6: We will sign and adhere to any non-disclosure or confidentiality agreement. We also have a strict policy within our factory that no photographs are ever allowed of a customer’s product without express permission. Ultimately we rely on our reputation of working with hundreds of thousands of unique designs over many years and never allowing any proprietary information to be disclosed to a third party.

A6: We will sign and adhere to any non-disclosure or confidentiality agreement. We also have a strict policy within our factory that no photographs are ever allowed of a customer’s product without express permission. Ultimately we rely on our reputation of working with hundreds of thousands of unique designs over many years and never allowing any proprietary information to be disclosed to a third party.

Hot Searches