- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

LISCA

-

Model Number:

-

L-SMS55

-

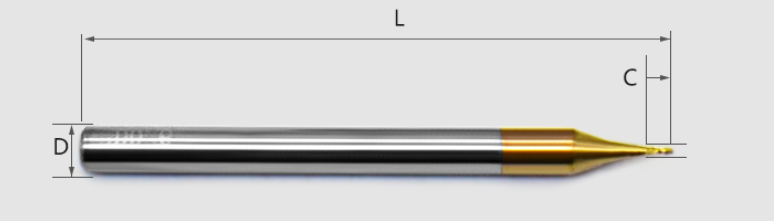

Product name:

-

Solid Carbide CNC Micro Ball End Mill Mini Diameter End Mills

-

Helix angle:

-

30/35/45 degree

-

Keyword:

-

Micro ball nose

-

Application:

-

Iron, Steels,copper,aluminum etc.

-

Suitable for:

-

high speed processing

-

HRC:

-

65

-

Shanke Diameter:

-

4MM

-

Packing:

-

1pcs/box

-

Flute type:

-

2

-

material:

-

tungsten carbide

Quick Details

-

Material:

-

Carbide

-

Coating:

-

AlTiSiN

-

Place of Origin:

-

Shanxi, China

-

Brand Name:

-

LISCA

-

Model Number:

-

L-SMS55

-

Product name:

-

Solid Carbide CNC Micro Ball End Mill Mini Diameter End Mills

-

Helix angle:

-

30/35/45 degree

-

Keyword:

-

Micro ball nose

-

Application:

-

Iron, Steels,copper,aluminum etc.

-

Suitable for:

-

high speed processing

-

HRC:

-

65

-

Shanke Diameter:

-

4MM

-

Packing:

-

1pcs/box

-

Flute type:

-

2

-

material:

-

tungsten carbide

Solid Carbide CNC Micro Ball End Mill Mini Diameter End Mills

Suitable Machine:Milling Machine, CNC processing center and so on.

HRC:65

Applications for:

Tool/Mould/Alloy/Carbon steel etc. high speed processing engraved and cutting.

Advantages:

1.Imported Tungsten Carbide rod.

2.Using Import ANCA Machine high precision grinding, polish processing.

3.Sharpen edge, big chips drain, wear resistance.

4.Many advantage coating choice and cut high hardness materials

Attention:

Please add cutting fluid in the milling process.

By DHL, FeDEX,UPS, and so on.