- Product Details

- {{item.text}}

Quick Details

-

Grade:

-

carbon steel

-

Place of Origin:

-

Hebei, China

-

Model Number:

-

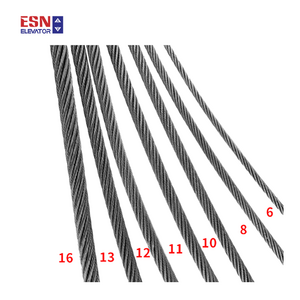

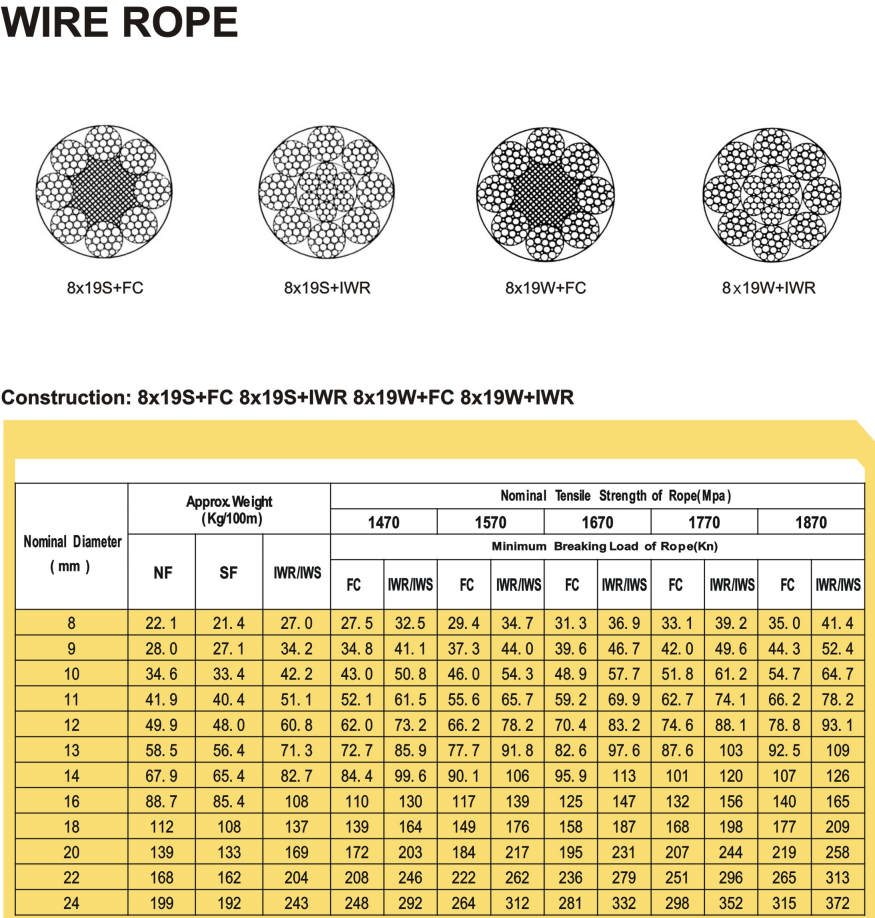

8x19 Steel wire rope

-

Surface treatment:

-

PVC coated, hot dip galvanized, electro galvanized, oil coated

-

OEM:

-

Yes

-

Model:

-

8x19S+FC Steel wire rope

Quick Details

-

Steel Grade:

-

steel

-

Type:

-

galvanized

-

Tolerance:

-

±1%

-

Grade:

-

carbon steel

-

Place of Origin:

-

Hebei, China

-

Model Number:

-

8x19 Steel wire rope

-

Surface treatment:

-

PVC coated, hot dip galvanized, electro galvanized, oil coated

-

OEM:

-

Yes

-

Model:

-

8x19S+FC Steel wire rope

Products Description

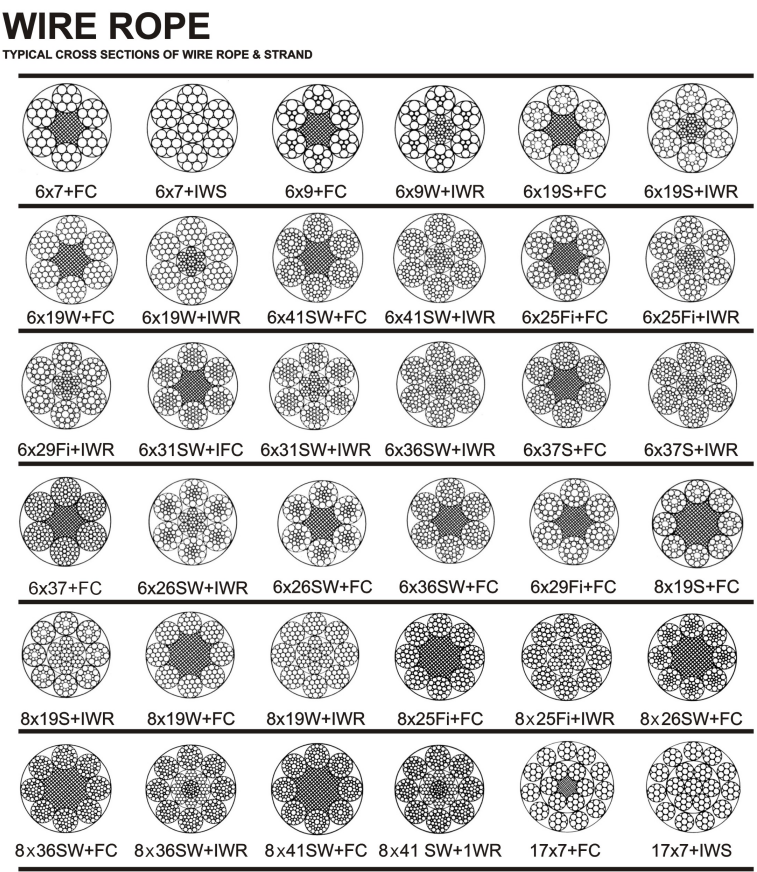

6x19S +7FC Customized Endless Steel Wire Rope

SELECTION, INSTALLATION, AND MAINTENANCE OF STEEL WIRE ROPE

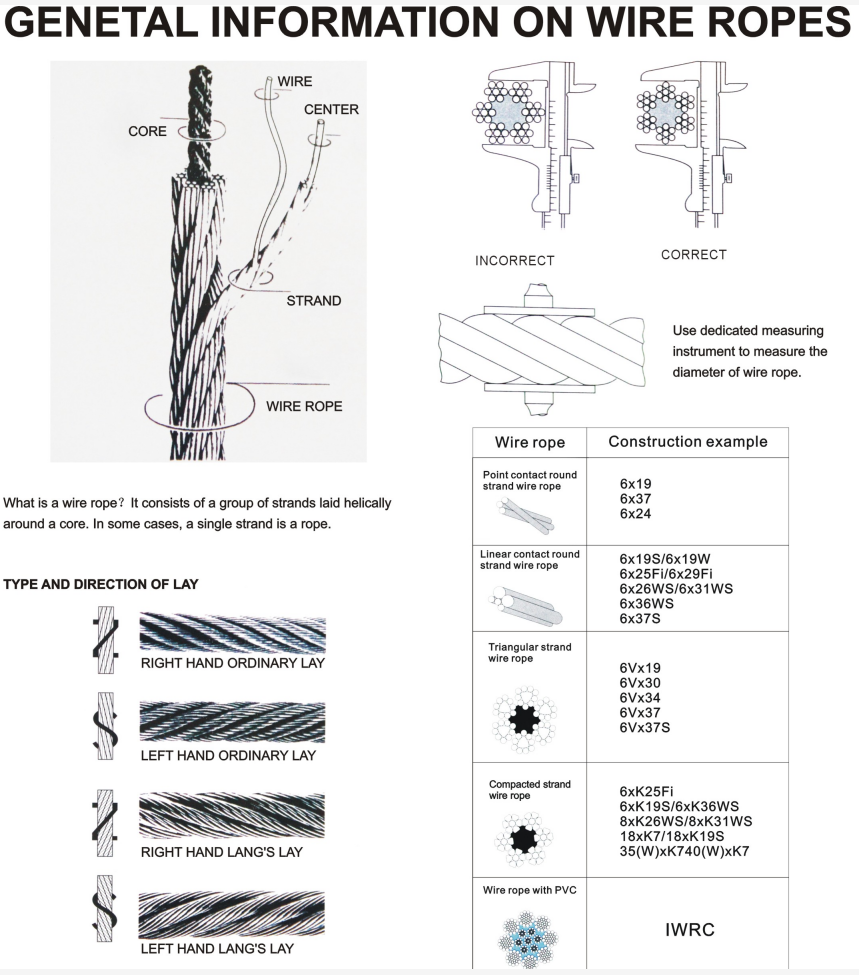

Selection of wire rope

Refer to GB8919-2006 “steel wire ropes for important purpose ” and GB/T20018-2006 “steel wire ropes for general purposes” on how to select from different constructions of wire rope. Please also refer to this section of our product catalogue in selecting wire rope, we suggest choosing equal lay steel wire rope. Compacted wire rope for general usage. The technical parameters such as lifting load, safety coefficient, and the lifting capacity of the lifting equipment should be taken into consideration when selecting the strength class of wire rope. Don’t blindly choose high strength and high breaking force wire rope, this may compromise results.

Maintenance and inspection of steel wire rope

Operation: in operation, the wire rope should be in steady speed, never overload, and never shock load a wire rope.

Maintenance: lubricant is applied to the wires and strands of a wire rope when manufactured. This lubricant is depleted when the rope is in service. And various nocuous matters will stick to the surface of the rope. It is important to clean and replace lubricant to the wire rope periodically.

Record of inspection: wire rope should be inspected regularly, and all the records should be kept carefully. Other than cleaning and adding lubricant, the inspection should include checking the following: abrasion of wire rope, condition of broken wires, and corrosion. Also check the condition of metal parts such as pulley grove, loading ring, hook, etc. Pay special attention and check for external and internal broken wires in the fixed end of wire rope, and the section of wire rope that passes through pulley blocks and drums.

Contact between wire rope and pulley groove

The appropriate contact between pulley groove and wire rope is indicated in. If the pulley groove is too wide, the wire rope and its metal core are subject to more broken wires owing to fatigue. If the pulley groove is too narrow, the wire rope will be worn serously. Theratio between the radius of pulley groove and that of the wire rope should be R/d=0.525~0.550.

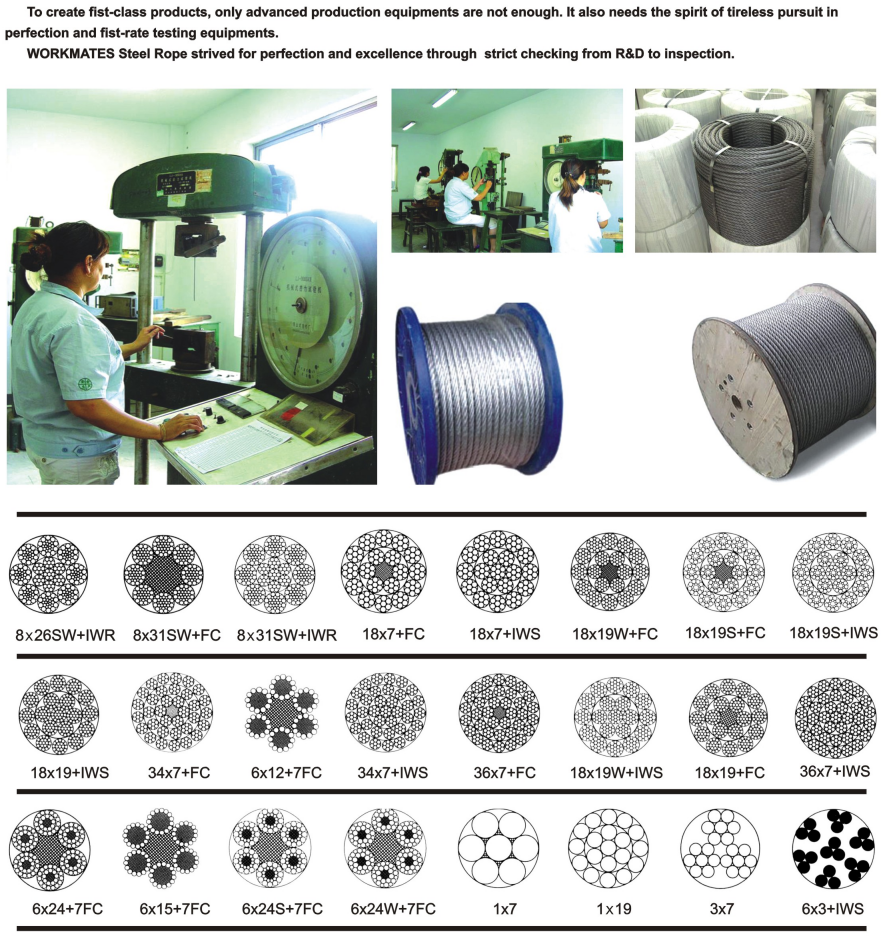

Factory & Exhibition

Certification

FAQ

|

Q1: How do you ensure your product and service quality?

|

|

We have a series of professional testing devices, and all the production line will strictly supervised by QC. We offer the test

report before shipment. |

|

|

|||

|

Q2: How about your delivery time?

|

|

Delivery time will be within 35 days since the PI is confirmed and received the advance payment.

|

|

|

|||

|

Q3: Can you provide sample?

|

|

Yes, we can provide you sample, but you need to pay for the sample and freight firstly.We will return the fee after you place the order.

|

|

|

|||

|

Q4: Can you use our brand?

|

|

Yes, OEM is available.

|

|

|

|||

Hot Searches