- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

YONGXIN

-

Weight:

-

60-Ton Approx.

-

Certification:

-

CE; ISO9001

-

Material:

-

Metal

-

502 Can Making Production Line CPM:

-

130Cans/min.

-

End Type Option:

-

Penny lever lid / EOE / POE

-

Can Making Machinery for Can Shape:

-

Round-Shape

-

Can Making Machinery for Thickness:

-

less 0.4mm

-

Power Supply Required:

-

380V 50Hz Three-phase Four-Wire

-

Standards:

-

Main electrical IEC60947

-

Shipment Lead Time:

-

8+WEEKS

-

#502 Can Packaging Making Line Power:

-

70 kva

Quick Details

-

Application:

-

Food, Milk Powder

-

Packaging Material:

-

Metal

-

Voltage:

-

380V AC Tailor-made

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

YONGXIN

-

Weight:

-

60-Ton Approx.

-

Certification:

-

CE; ISO9001

-

Material:

-

Metal

-

502 Can Making Production Line CPM:

-

130Cans/min.

-

End Type Option:

-

Penny lever lid / EOE / POE

-

Can Making Machinery for Can Shape:

-

Round-Shape

-

Can Making Machinery for Thickness:

-

less 0.4mm

-

Power Supply Required:

-

380V 50Hz Three-phase Four-Wire

-

Standards:

-

Main electrical IEC60947

-

Shipment Lead Time:

-

8+WEEKS

-

#502 Can Packaging Making Line Power:

-

70 kva

MACHINES SALES GUIDE:

BEFORE YOU READ FOLLOWING INFO., PLEASE PERPARE YOUR QUESTIONS TO GET MY SPECIFIC TURN-KEY SOLUTION OFFER FOR YOU. CHEERS!

1. What's your tin can look like and special requirement?

2. What's your tin can Dimensions?

3. What's your demand for production capacity (CPM)?

4. More information please go to www.jeitco.com

| Related Equipment |

Tailor Made Turn Key Solution #502 Milk Powder Protein Metal Can Packaging Making Machinery

| MACHINE BOM | |||||

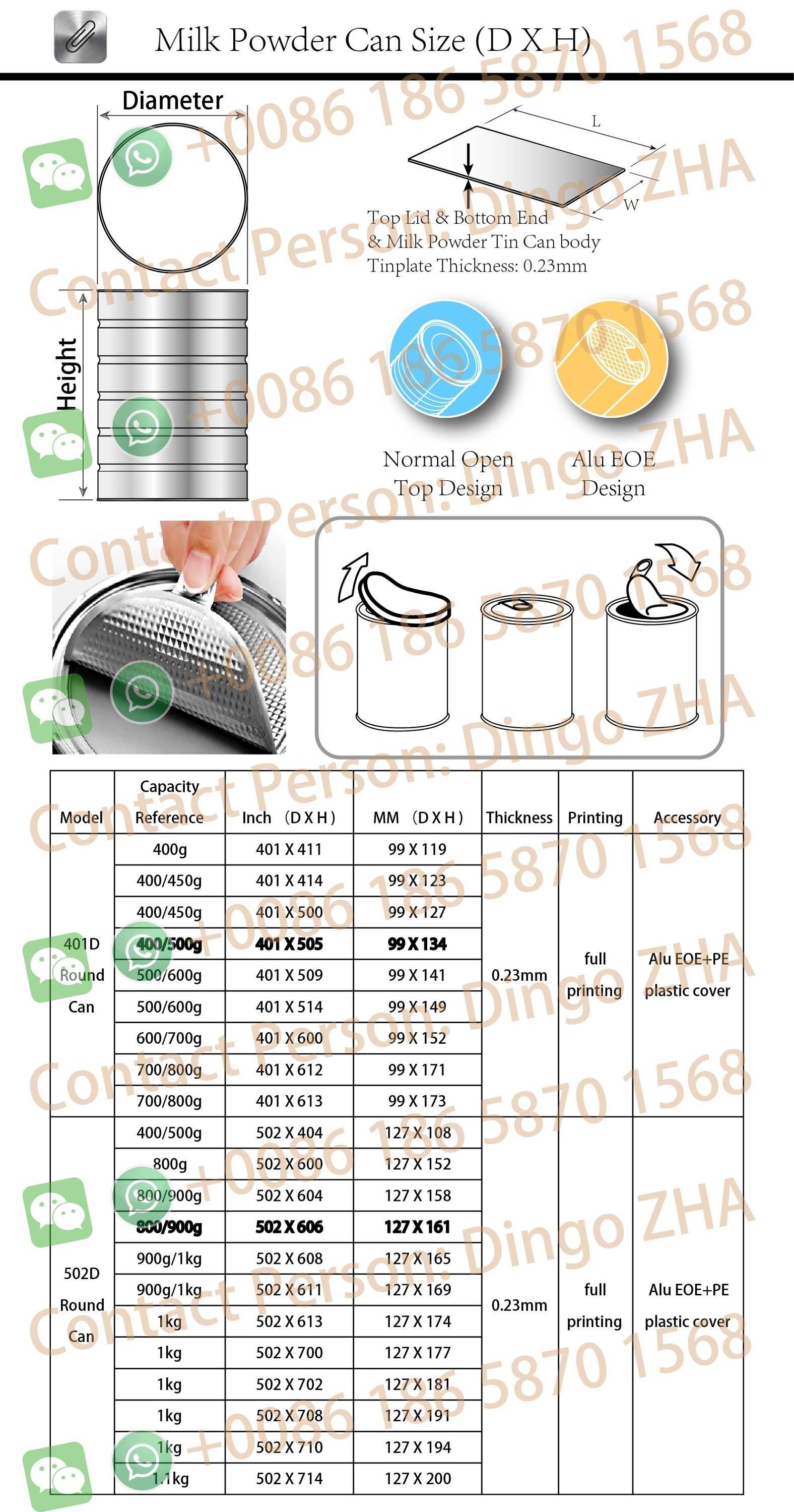

| Take a typical example for Milk Powder Tin Can Size: D127mm X H161 (Can Code 502 X 606) | |||||

| Milk Powder Tin Can Body AUTOMATIC Making Line | Model | CPM | Power | Qty. | UOM |

| High-Speed Duplex Slitting Machine ( Machine Link ) | GT1B6 | 0-30 | 6.5 KVA | 1 | SET |

| High-Speed Automatic Welding Machine with Can body Roll-forming function ( Machine Link ) | FH18-65ZDS | 100-120 | 40.0 kVA | 1 | SET |

| Water Chiller ( Machine Link ) | YMWC | NULL | 3.5 kVA | 1 | SET |

| Nitrogen Generator (Tailor-made) (Machine Link) | NULL | NULL | NULL | 1 | SET |

| Internal Coating Machine ( Machine Link ) | CTPC-2 | 35 | 2.8 kVA | 1 | SET |

| External Lacquering Machine ( Machine Link ) | GNWT-180S | 18 | 0.5 kVA | 1 | SET |

| High Frequency Electromagnetic Drying Machine (Tailor-made) ( Machine Link ) | GDCHG-286 | 30 | 8.0 kVA | 1 | SET |

| V-Type Standing-Up Conveyor (Tailor-made) (Machine Link ) | TD2 | NULL | 1.5 kVA | 1 | SET |

| High-Speed Tri-Station Combination Machine (Flanging+Beading+Seaming) ( Machine Link ) | GT3B42FBS-2 (6H) | 130 | 7.5 kVA | 1 | SET |

| Milk Powder Tin Can Lid/End AUTOMATIC Making Line | Model | CPM | Power | Qty. | UOM |

| Standard Deep Throat Punching Press Machine ( Machine Link ) | J21S-16 | NULL | 1.5 kVA | 4 | SET |

| Auto Feed-in System Device (Tailor-made) (Machine Link) | NULL | NULL | NULL | 1 | SET |

| End Die Set (Tailor-made) ( Contact Dingo ) | NULL | NULL | NULL | 4 | SET |

| Round Lid Curling & Lining Compound Combination Machine (Machine Link) | GT | 80 | 2.0 kVA | 1 | SET |

| Round Lid Drying Machine (Tailor-made) ( Machine Link ) | CT2D5 | NULL | 12.0 kVA | 1 | SET |

| Aluminum-Foil Peel-off Lid (Alu. EOE) (Machine Link) | |||||

| PE Plastic Cover on Lid (Machine Link) | |||||

Pulling it all together! - full turn key assembly solution projects, i n such case the purpose of using a turn key solution is to avoid the hassle or headache of setting up your own in-house tin can making solution, include design, manufacturing, shipping, testing and commissioning of on turn key basis. The assembling plant should have a production capacity of yearly 3.5 million cans, considering 80% uptime and man-power single shift of operation.