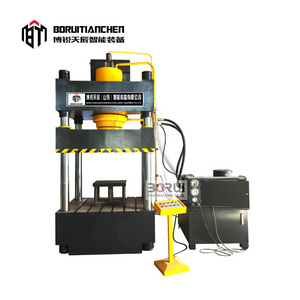

The main function:

Our machine can realize the whole process from feeding, pressing and discharging. The whole process is easy to operate and very convenient.W

e put a matching automatic loading hopper in the rear, in order to make the structure layout more reasonable and the space layout more compact, so that we can use a smaller space to place it.

Product main technical specifications:

Product main technical specifications: