- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

1300*2500mm

-

Cutting Thickness:

-

0-30mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Shandong, China

-

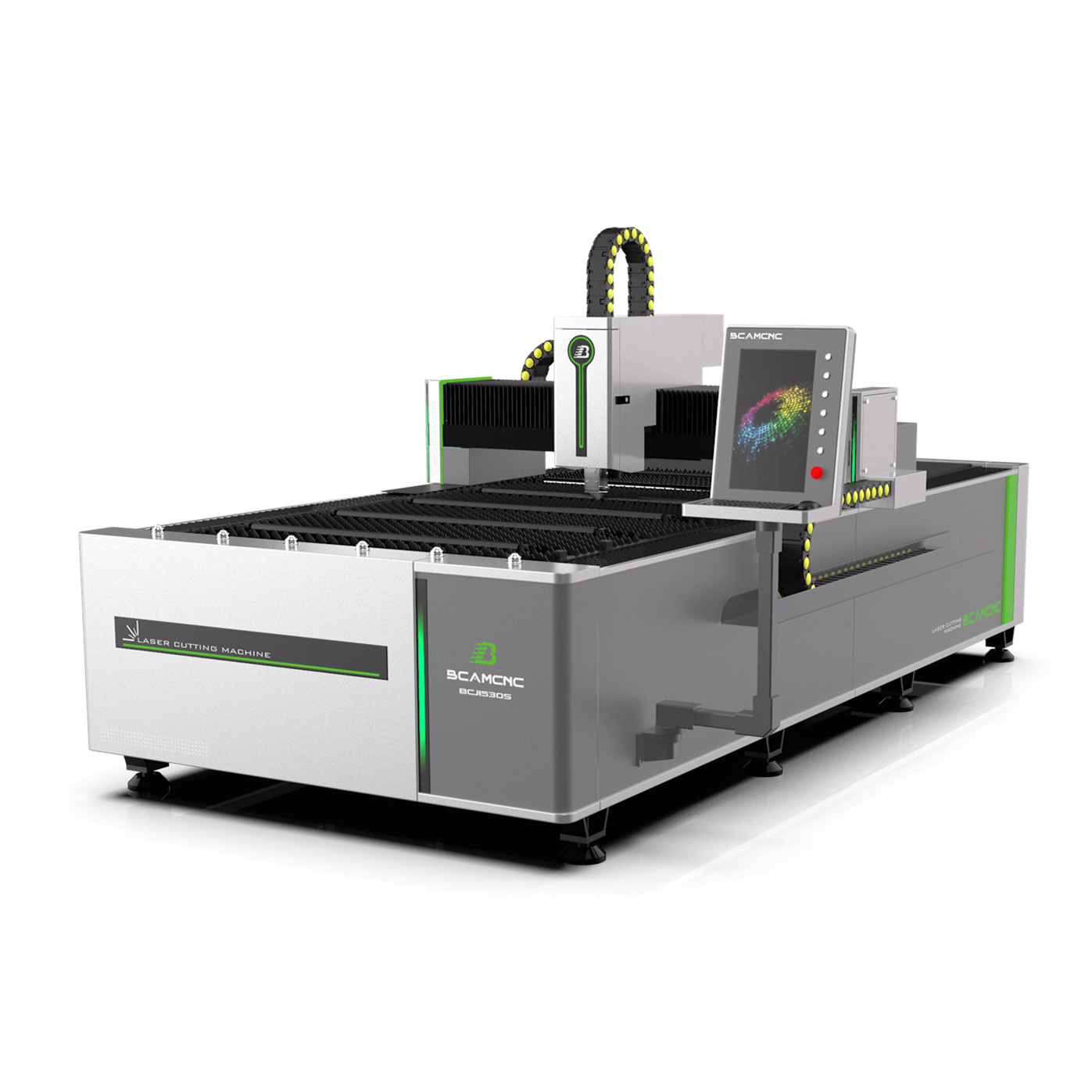

Brand Name:

-

BCAMCNC

-

Weight (KG):

-

3000 KG

-

Product name:

-

cnc cutting laser fiber cutting machine for 2mm Ss CS metal sheet

-

Laser power:

-

Raycus 500W / 1000W(option: IPG)

-

Cutting materials:

-

stainless steel, carbon steel, aluminum, copper etc

-

Control system:

-

Cypcut Control System

-

Driving system:

-

X/Y axis Yaskawa and Z axis Panasonic

-

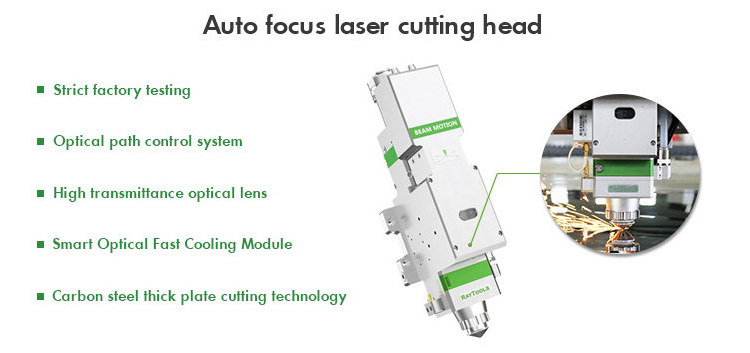

Laser head:

-

WSX Worthing cutting head

-

Table:

-

Serrate working platform

-

Positioning Accuracy:

-

±0.02mm

-

Working speed:

-

different speed for different thicknes

-

Max cutting speed:

-

24m/min

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

24m /min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

1300*2500mm

-

Cutting Thickness:

-

0-30mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

BCAMCNC

-

Weight (KG):

-

3000 KG

-

Product name:

-

cnc cutting laser fiber cutting machine for 2mm Ss CS metal sheet

-

Laser power:

-

Raycus 500W / 1000W(option: IPG)

-

Cutting materials:

-

stainless steel, carbon steel, aluminum, copper etc

-

Control system:

-

Cypcut Control System

-

Driving system:

-

X/Y axis Yaskawa and Z axis Panasonic

-

Laser head:

-

WSX Worthing cutting head

-

Table:

-

Serrate working platform

-

Positioning Accuracy:

-

±0.02mm

-

Working speed:

-

different speed for different thicknes

-

Max cutting speed:

-

24m/min

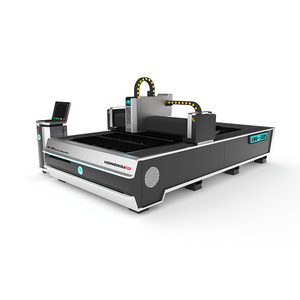

Economical cnc fiber laser cutting machine 3kw 6kw metal laser cutter steel cutting machine for sale

product description

Features:

1) Gantry CNC machine and high strength welding body . After high temperature annealing and precision machining by large CNC milling machine, it has good rigidity and stability.

2) Adopts imported high precision, high speed, linear guide rail drive, good rigidity and good stability.

3) Aluminum beam, advanced heat treatment process, high strength, light weight, good rigidity.

4) Fiber laser has a series of advantages, such as high beam quality, high brightness, high conversion rates, maintenance-free , stable and reliable operation of low cost and small size, etc.

5) Adopting servo motor and driver, and combind Japan Reducer, which can make sure machine high speed and big power.

1) Gantry CNC machine and high strength welding body . After high temperature annealing and precision machining by large CNC milling machine, it has good rigidity and stability.

2) Adopts imported high precision, high speed, linear guide rail drive, good rigidity and good stability.

3) Aluminum beam, advanced heat treatment process, high strength, light weight, good rigidity.

4) Fiber laser has a series of advantages, such as high beam quality, high brightness, high conversion rates, maintenance-free , stable and reliable operation of low cost and small size, etc.

5) Adopting servo motor and driver, and combind Japan Reducer, which can make sure machine high speed and big power.

|

Model

|

BCJ3015T

|

|

Working raea

|

1500*3000mm

|

|

Optional size

|

1300*2500mm, 2000*3000mm, 2000*4000mm, 2000*5000mm, 2000*6000mm,...

|

|

Laser source

|

Raycus 1000w

|

|

Laser source

|

Raycus 1000w

|

|

Optional power

|

500w, 750w, 1500w, 2000w,3000w, 4000w, 5000w (Raycus and IPG)

|

|

Max. moving speed

|

100m/min

|

|

Max. cutting speed

|

35m/min

|

|

Positioning accuracy

|

0.03mm

|

|

Repeated positioning accuracy

|

0.02mm

|

|

Min. line width

|

0.01mm

|

|

Continuous working time

|

24 hours

|

|

Gross weight

|

2500kgs

|

|

Machine size (L*W*H)

|

49350*2280*2000

|

Details

Applications&Samples

metal plates, tubes: stainless steel, carbon steel, manganese steel, galvanized sheet,alloy plates, rare metal

Application Industry

Industry of kitchen ware, lamps and lanterns, panel beating, metal cabinets, auto parts, refrigerators, air condition, elevators, hotel metal supplies processing, etc

our advantages

Fiber laser cutter's configuration

1.Swiss brand Raytools laser cutting head ,Germany brand Precitec laser cutting head as optional

2.Japan Yaskawa servo motor and drivers

3.Germany Atlanta Gear and Rack

4.French Motoreducer ,Germany Neugart Reducer as optional

5.IPG Laser source or Raycus laser source

6.BCM3015 equipped with exchange table and control cabinet

7.Taiwan Hiwin linear guide rail and cypcut operating system

1.Swiss brand Raytools laser cutting head ,Germany brand Precitec laser cutting head as optional

2.Japan Yaskawa servo motor and drivers

3.Germany Atlanta Gear and Rack

4.French Motoreducer ,Germany Neugart Reducer as optional

5.IPG Laser source or Raycus laser source

6.BCM3015 equipped with exchange table and control cabinet

7.Taiwan Hiwin linear guide rail and cypcut operating system

Related Products

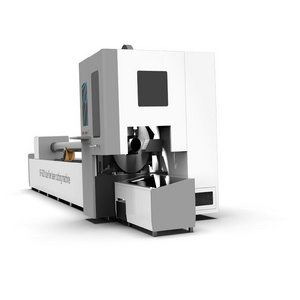

Enclosed

exchange table

fiber laser cutting machine

Packing & Delivery

1.

Anti-collision package edge:

All parts of the fiber laser welding machine are covered with some soft materials, mainly the use of pearl wool .

2. Fumigation wooden box: Our wooden box is fumigated, do not need to check the wood, saving the transport time.

3. Whole film packaging machine: Avoid all damage that may occur during delivery. Then we will cover the plastic package tightly to ensure that the soft material is covered intact, also avoiding water and rust.

4. Wooden box at the bottom of a solid iron socket for easy handling.

2. Fumigation wooden box: Our wooden box is fumigated, do not need to check the wood, saving the transport time.

3. Whole film packaging machine: Avoid all damage that may occur during delivery. Then we will cover the plastic package tightly to ensure that the soft material is covered intact, also avoiding water and rust.

4. Wooden box at the bottom of a solid iron socket for easy handling.

How is the packing?

1).With Standard plywood case, its compressive strength and bearing quality is better.

2).The board area is bit, the soil structure is good, it is better in leakproofness and waterproof.

3).When importing, the plywood case is with fumigation-free, the procedure is simple.

2.How long is the delivery time?

For standard machine, it would be 7-10 working days;

For non-standard and customized machines according to client's specific requirements, it would be 15-30 working days.

1).With Standard plywood case, its compressive strength and bearing quality is better.

2).The board area is bit, the soil structure is good, it is better in leakproofness and waterproof.

3).When importing, the plywood case is with fumigation-free, the procedure is simple.

2.How long is the delivery time?

For standard machine, it would be 7-10 working days;

For non-standard and customized machines according to client's specific requirements, it would be 15-30 working days.

About us

BCAM has more than

15 years of experience

and has built and installed thousands of machines for industries including Aluminum & Metal Composite Cladding, Signmaking, Graphics &Print Finishing, Cabinetry, Woodworking, Plastic Fabrication, Metal Fabrication, Foam Packaging, Point of Purchase, Solid Surface etc.

TEAM SHOW

BCAM values every employee and strives to make everyone safe,healthy and happy. Weput safety first and have set ambitious goals to prevent all injuries, occupational diseases and safety incidents. Our commitment to safety practices runs through the entire value chain from supplier to customer.Weare committed to providing our customers with safe and reliable products and services

FAQ

Q1: How do I get the best price?

A: Different type of CNC machine apply to the different price.

Q2: What machine suits me best?

A: Different material and the different model apply to the different machine.Please tell us what's material you want to cutting or engraving ?And what's MAX size of carved material ?We will recommend the most suitable model and the best price for you.

Q3: What should I do if the machine fails during warranty period?

A: Just contact us----our sales are online for 24-hours and ready to help.Replacement of damaged parts for free(make sure it is not broken because of wrong operation).The CD and operation manual----It shows the most common failures in working processing and how to solve the problems.

Q4: Are you trading company or manufacturer?

A: We are a factory direct sale, can guarantee you got the best product at the best price.All the products have CE, ISO

certifications, all the machines are tested well before delivery. There is a 12 months warranty.

Q5: How long is your delivery time?

A:Generally it is a weekday if the goods are in stock. or it is 15 working days if the goods are not in stock, it is according to your quantity.

A: Different type of CNC machine apply to the different price.

Q2: What machine suits me best?

A: Different material and the different model apply to the different machine.Please tell us what's material you want to cutting or engraving ?And what's MAX size of carved material ?We will recommend the most suitable model and the best price for you.

Q3: What should I do if the machine fails during warranty period?

A: Just contact us----our sales are online for 24-hours and ready to help.Replacement of damaged parts for free(make sure it is not broken because of wrong operation).The CD and operation manual----It shows the most common failures in working processing and how to solve the problems.

Q4: Are you trading company or manufacturer?

A: We are a factory direct sale, can guarantee you got the best product at the best price.All the products have CE, ISO

certifications, all the machines are tested well before delivery. There is a 12 months warranty.

Q5: How long is your delivery time?

A:Generally it is a weekday if the goods are in stock. or it is 15 working days if the goods are not in stock, it is according to your quantity.

Hot Searches