- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ABB,Kawasaki,KUKA,FANUC

-

Dimension(L*W*H):

-

2250*2250*3890

-

Weight:

-

1001 KG

-

Product name:

-

Column Robot palletizer

-

Function:

-

Bag palletizing

-

Speed:

-

350-500bags/h

-

Certification:

-

CE Certfication

-

Material:

-

Carbon Steel

Quick Details

-

Application:

-

Food, Beverage, Commodity, Chemical, Machinery & Hardware

-

Packaging Material:

-

Plastic

-

Voltage:

-

220V/380V 50Hz 3Phase

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ABB,Kawasaki,KUKA,FANUC

-

Dimension(L*W*H):

-

2250*2250*3890

-

Weight:

-

1001 KG

-

Product name:

-

Column Robot palletizer

-

Function:

-

Bag palletizing

-

Speed:

-

350-500bags/h

-

Certification:

-

CE Certfication

-

Material:

-

Carbon Steel

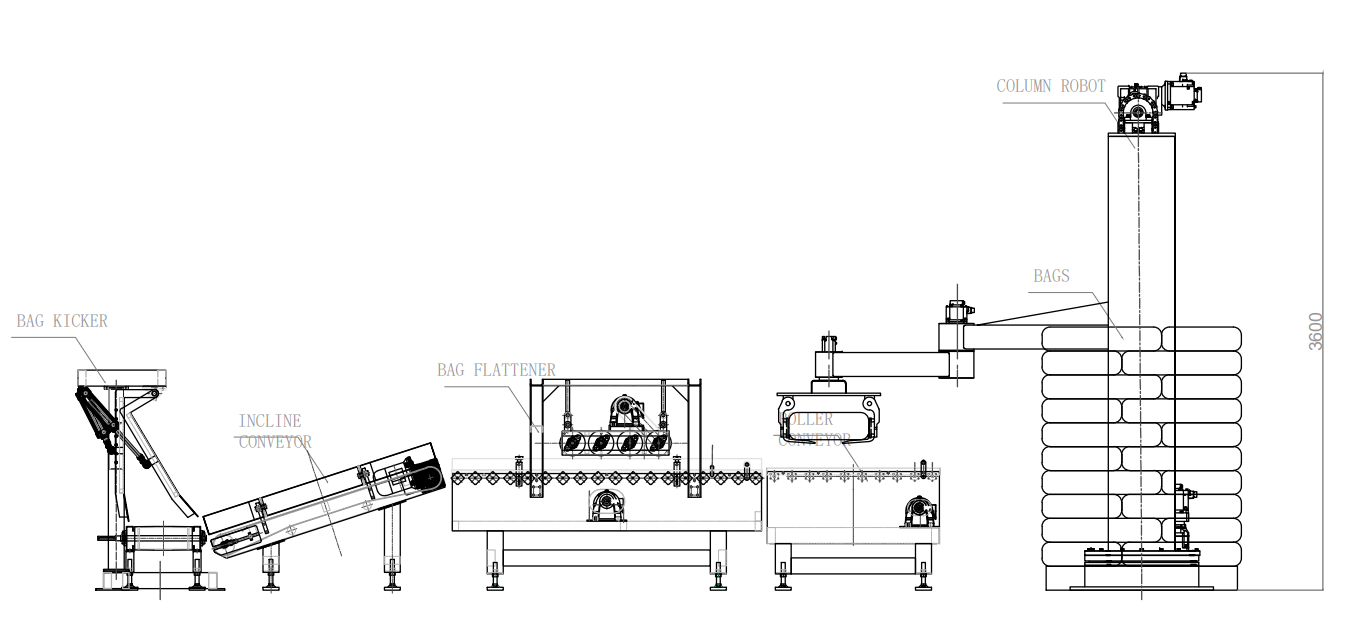

MACHINE SHOW

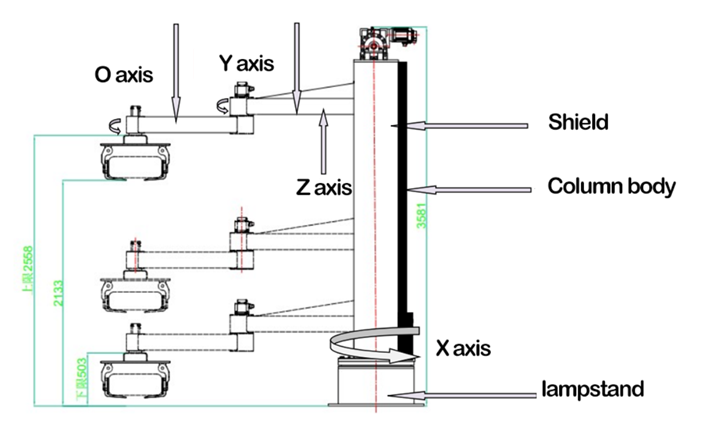

Single Column Robot Palletizer

Brief

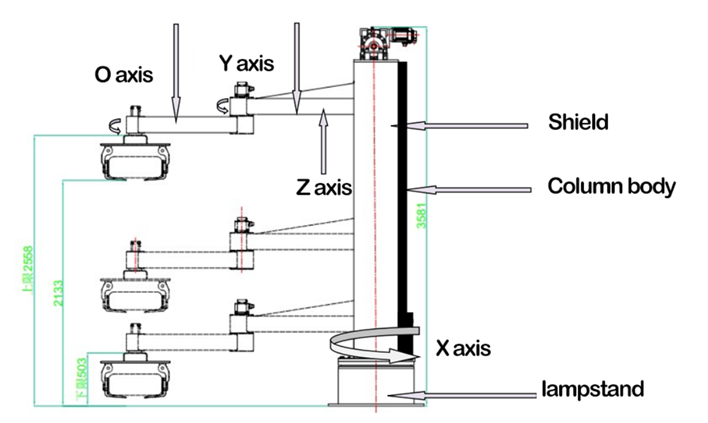

In the range of robot palletiser made by ZHENGXIA, the single-column robot palletizer represents the simplest and most compact model.

The single-column robot palletiser can handle bags containing stable, aerated or powdery products, permitting partial overlapping of the bags in the layer along both the top and sides, offering flexible format changes.Its extreme simplicity makes it possible to palletise even on pallets sitting directly on the floor.

Work Process

The machine features a sturdy rotating column with a rigid horizontal arm connected to it that can slide vertically along the column. The horizontal arm has a bag pick-up pincer mounted on it that slides along it, rotating around its vertical axis.The machine takes the bags one at a time from the roller conveyor on which they arrive and places them at the point assigned by the program.The horizontal arm descends to the necessary height so that the pincer can pick up the bags from the bag infeed roller conveyor and then it ascends to permit free rotation of the main column.

The pincer traverses along the arm and rotates around its axis to place the bag in the position assigned by the programmed palletising pattern.

The arm is positioned at the required height and the pincer opens to place the bag on the pallet being formed. At this point, the machine returns to the starting point and is ready for a new cycle.

|

Brand

|

ZHENGXIA

|

|

Palletizer speed

|

250-350 bags/h

|

|

Workable bag weights

|

from 1 to 50 kg

|

|

Stacking Type

|

5/6/7/8/9/10 bags per layer or customized

|

|

Voltage

|

220v/380v 50 hz or Customized

|

|

Working Temperature

|

-20~50℃

|

|

Operating system

|

PLC

|

|

Application

|

bags, cases, boxes, bottles, barrels

|

PRODUCT DETAILS

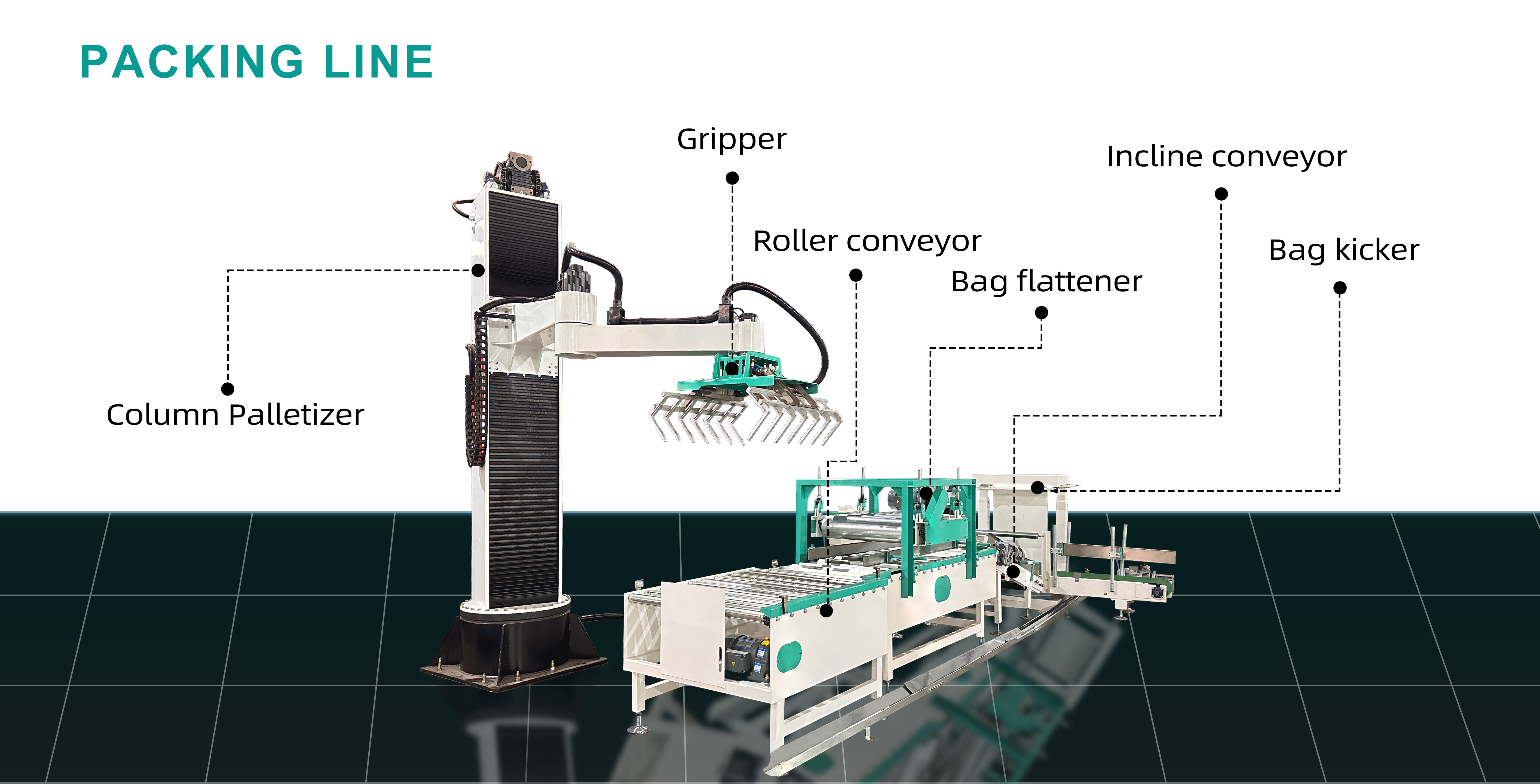

Palletizing Line

Single Column Palletizer

The special construction solution gives the single-column robot palletizers unique features:

* Possibility of palletizing from several pickup points, in order to handle bags from different lines in one or more palletizing points.

* Possibility of palletizing on pallets set directly on the floor.

* Very compact size

The machine features a PLC-controlled operating system.

Through special programs, the machine can perform virtually any type of palletizing program.

The format and program changes are carried out automatically and very quickly.

The single-column robot palletizer comes complete with safety devices compliant with current international standards .

* Possibility of palletizing from several pickup points, in order to handle bags from different lines in one or more palletizing points.

* Possibility of palletizing on pallets set directly on the floor.

* Very compact size

The machine features a PLC-controlled operating system.

Through special programs, the machine can perform virtually any type of palletizing program.

The format and program changes are carried out automatically and very quickly.

The single-column robot palletizer comes complete with safety devices compliant with current international standards .

Bag Kicker

Standing bags are transported to this position, and through the detection of photoelectric switches, it is judged whether the bag has reached the position of pushing the bag. After arriving, the cylinder works and kicks the bag down to a horizontal state and transports it to the Incline Conveyor.

Incline Conveyor

The Incline conveyor is mainly used for the transportation of the product. Inclined conveying makes the material inside the bag flat, ready for the next step of shaping and at the same time play the role of cache packing bags .

Bag Flattener

The bag is shaped and flattened by the square roller vibrating conveyor , so that the palletizing shape is neat and secure,The shaping conveyor can open a certain distance between the products, which is convenient for photoelectric detection and subsequent palletizing.

Roller Conveyor

The bag is conveyed to the Roller Conveyor, the sensors on both sides will detect the bag, stop the conveying and link the palletizer to grab the bag.

Optional Device

MACHINE COMPONENTS

PROJECT SHOW

COMPANY PROFILE

PACKAGING & DELIVERY

CONTACT US

FAQ

Q1: Are you factory or trading company?

A1: We are the factory, we doing this line for more than 10 years.

Q 2: How many types of palletizers do you have?

A2: Column Palletizer,High level Palletizer,Low level Palletizer and Robot Palletizer.

Q3: How to ensure the quality of the machine?

A3: We usually delivery the machine after successful inspection in our factory. We have our own quality control department,beforethe delivery we have to running the machine for three days without problem. You can send us your materials and we will make video as long as you want. Or you can arrange a third-party inspection agency.

Q4: How to install the equipment?

A4: We will provide manuals and detailed videos to help customer install machine. If necessary, we will send technicians to the customer's factory to assist, and the customer only needs to pay for round-trip air tickets, meals, room expenses and a daily subsidy of 150 US dollars.

Q5: What's your payment way?

A5: T/T by our bank account directly, or by Alibaba trade assurance service, or by West Union, or L/C.

A1: We are the factory, we doing this line for more than 10 years.

Q 2: How many types of palletizers do you have?

A2: Column Palletizer,High level Palletizer,Low level Palletizer and Robot Palletizer.

Q3: How to ensure the quality of the machine?

A3: We usually delivery the machine after successful inspection in our factory. We have our own quality control department,beforethe delivery we have to running the machine for three days without problem. You can send us your materials and we will make video as long as you want. Or you can arrange a third-party inspection agency.

Q4: How to install the equipment?

A4: We will provide manuals and detailed videos to help customer install machine. If necessary, we will send technicians to the customer's factory to assist, and the customer only needs to pay for round-trip air tickets, meals, room expenses and a daily subsidy of 150 US dollars.

Q5: What's your payment way?

A5: T/T by our bank account directly, or by Alibaba trade assurance service, or by West Union, or L/C.

Hot Searches