- Product Details

- {{item.text}}

Quick Details

-

Color:

-

White

-

Main Composition:

-

Mg3K[AlF2O(SiO3)3],SiO2

-

Density:

-

2.6 g/cm3

-

Dimension:

-

Customized Dimensions

-

Gas Permeability:

-

0.07%

-

Water Absorption:

-

0

-

Rockwell Hardness(45N):

-

40

-

Flexural Strength:

-

108 Mpa

-

Compressive Strength:

-

488 Mpa

-

Thermal Conductivity:

-

1.71 W(m.K)

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Model Number:

-

Macor 008

-

Brand Name:

-

HaiKun

-

Color:

-

White

-

Main Composition:

-

Mg3K[AlF2O(SiO3)3],SiO2

-

Density:

-

2.6 g/cm3

-

Dimension:

-

Customized Dimensions

-

Gas Permeability:

-

0.07%

-

Water Absorption:

-

0

-

Rockwell Hardness(45N):

-

40

-

Flexural Strength:

-

108 Mpa

-

Compressive Strength:

-

488 Mpa

-

Thermal Conductivity:

-

1.71 W(m.K)

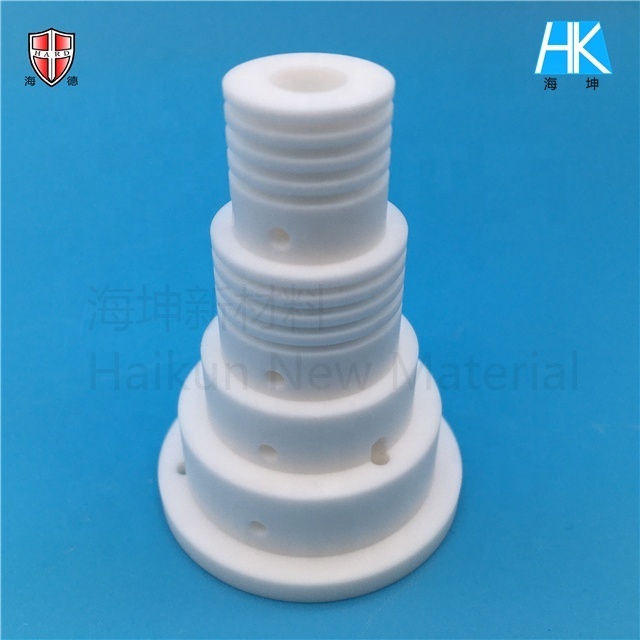

complicated advanced special macor machinable ceramic structural parts

Reputation depends on quality, quality comes from Haikun!

Macor (Mica Glass) Ceramic:

Microcrystalline glass ceramics, also known as machinable ceramics, are mica glass-ceramics with synthetic mica as the main crystalline phase, and are ceramic materials that can be machined. Microcrystalline glass ceramics have excellent processing properties, vacuum properties, electrical insulation properties, and high temperature and chemical resistance. Glass-ceramics with high mechanical strength, glass-ceramics, machinable glass-ceramics and bioactive glass-ceramic.

Machinable Ceramic Properties:

Good insulativity, high temperature(800°) but very low thermal conductivity, good machinable property, easy to machining, can be made of rod and plate in short time.

Application industry : Machinery, electronic, limitary, aerospace etc.

Specific application : Machined equipment high temperature insulated parts, electronic equipment high temperature insulated parts.

Data Sheet↓

| Machinable Mica Glass (Macor) Ceramic Properties | ||

| Item | Unit | Typical Values |

| Physical Properties | ||

| Color | White | |

| Main Composition | Mg3K[AlF2O(SiO3)3],SiO2 | |

| Density | g/cm3 | 2.60 |

| Apparent Porosity | 0.07% | |

| Water Absorption | 0 | |

| Normal Temperature Outlet Rate | ml/S·cm2 | 8.8*10-9 |

| Helium Transmission Rate | ml/S | 1*10-10 |

| Mechanical Properties | ||

| Rockwell Hardness(45N) | R45N | 40 |

| Vickers Hardness (Load 500g) | Gpa(Kg/mm2) | 11.5(1175) |

| Flexural Strength (20°C) | Mpa | >108 |

| Compressive Strength (20°C) | Mpa | 488 |

| Modulus of Elasticity (25°C) | Gpa | 65 |

| Impact Toughness | KJ/m2 | >2.56 |

| Thermal Properties | ||

| Thermal Conductivity (25°C) | W/m.K | 1.71 |

| Thermal Expansion Coefficient | 10-6/°C | 7.2 |

| Thermal Shock Resistance | T°C | 200 |

| Maximum Working Temperature | °C | 800 |

| Electric Properties | ||

| Dielectric Strength | KV/mm | >40 |

| Volume Resistivity(25°C) | Ω.cm | 1.08*1016 |

| Volume Resistivity(200°C) | Ω.cm | 1.5*1012 |

| Volume Resistivity(500°C) | Ω.cm | 1.1*109 |

| Dielectric Loss | 1-4*10-3 | |

| Dielectric Constant | Er | 6-7 |