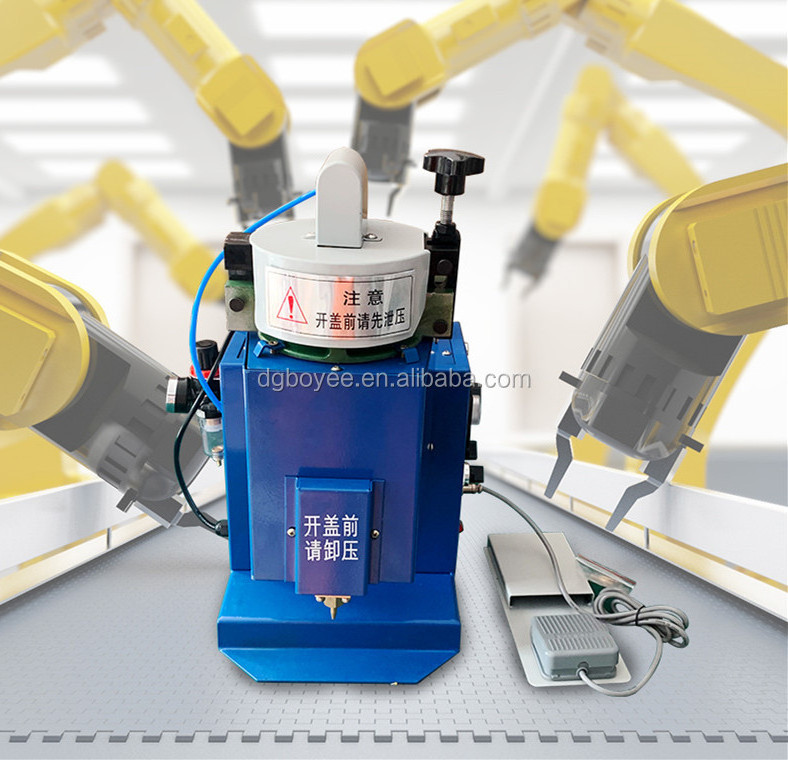

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

52 (L) * 30 (W) * 40 (H)

-

Weight:

-

22 KG

-

Max operation TEMP:

-

200℃

-

Power(W):

-

850W

-

Maximum viscosity:

-

1200000(pcs)

-

Air pressure:

-

4-6 kg/m

-

Max.melting rate:

-

2.5 kg/hour

-

After Warranty Service:

-

Video technical support

Quick Details

-

Voltage:

-

110/220V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

BOYEE

-

Dimension(L*W*H):

-

52 (L) * 30 (W) * 40 (H)

-

Weight:

-

22 KG

-

Max operation TEMP:

-

200℃

-

Power(W):

-

850W

-

Maximum viscosity:

-

1200000(pcs)

-

Air pressure:

-

4-6 kg/m

-

Max.melting rate:

-

2.5 kg/hour

-

After Warranty Service:

-

Video technical support

Product Description

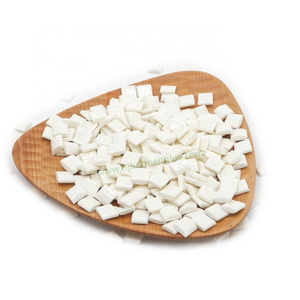

Gluing Method:

Spot spraying strip spraying, mist spraying or scraper nozzle gluing

Application:

Widely used in footwear, packing woodwork, textile,toy-making.leather wares.non-woven.electronics,electrical instruments and other industry.

It can replace manual hot melt glue gun, save labor and fast, heating and constant temperature has stronger viscosity.Precisely control glue dispensing boxes, electronic products, etc.

Feature:

1) small light,multiple-function, and space-saving

2) Mist spraying in vamp,inner,heels of shoes

3) optional scraper nozzle(2-10mm width) can replace double sided tape.

SPECIFICATION

Demension(L*W*H): 52 (L) * 30 (W) * 40 (H)

Weight: 16KG

Air pressure: 4-6 Kg/cm2

Tank Capacity :2.0 Litter

Max. malting rate: 2.5 Kg/Hour

Max. Operation temp. : 200 °C

Max. CPS: 12000 CPS

Security

Wear safety gloves, goggles, and long-sleeved overalls to avoid scalds and burns from hot melted glue.

1. Introduce a clean, filtered air source

2. The hot melt glue added inside the machine does not exceed 7/10 of the internal volume

3. The maximum total pressure is set to 4 kg

4. Before heating the machine, the pressure of the rubber storage cylinder must be released first

Preparation before operation:

1. It is strongly recommended that the operator take safety precautions before operation.

2. Check the remaining volume of the plastic storage cylinder, and do not exceed 7/10 of the volume of the plastic cylinder.

3. Check whether the temperature of the rubber cylinder is set at about 170°C. Different hot melt adhesives have different softening points. For specific setting values, please refer to the data provided by the hot melt adhesive supplier.

4. Check whether the foot switch is connected and there is no conductive object contacting the components of the electrical box.

5. Check if the air supply system is dry and the air pressure is stable.

6. Power on and test each part of the circuit to see if the air circuit can work normally.

Boot steps:

Connect the power, turn on the power switch and turn it on

Check whether the temperature of the temperature controller is present.

Check whether the blood pressure is in the direction of holding pressure.

Connect the air source, set the pressure value, and start operation.

Shutdown steps:

Release the foot switch to cut off the power of the host

Disconnect the air pipe or adjust the pressure regulator of the water filter cup to zero.

Precautions for hot melt adhesive:

When heating the glue storage cylinder to melt glue, turn on the pressure relief switch first.

Open the lid of the plastic bucket and add hot melt glue after the pressure is relieved.

Be careful not to exceed 7/10 of the traffic when heating the glue.

Lock the lid of the plastic bucket after adding the hot melt glue.

Hot Searches