- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

L11000 X W3000 X H1600

-

Weight:

-

8000 KG

-

Product name:

-

automatic folding gluing machine

-

Function:

-

Folding and gluing Corrugated Carton Box

-

Feeding way:

-

Automatic Feeding

-

Glue type:

-

Cold Glue

-

Machine type:

-

Automatic Folding Paper Box Folder Gluing Machine

-

Usage:

-

carton box folder gluer

-

After-sales Service Provided:

-

Online Support

-

Paper material:

-

3/5/7 ply corrugated cardboard

-

Speed:

-

150PCS/MIN

-

Suitable material:

-

3/5 layer corrugated cardboard paper board

Quick Details

-

Voltage:

-

380V or custom made

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Lighten

-

Dimension(L*W*H):

-

L11000 X W3000 X H1600

-

Weight:

-

8000 KG

-

Product name:

-

automatic folding gluing machine

-

Function:

-

Folding and gluing Corrugated Carton Box

-

Feeding way:

-

Automatic Feeding

-

Glue type:

-

Cold Glue

-

Machine type:

-

Automatic Folding Paper Box Folder Gluing Machine

-

Usage:

-

carton box folder gluer

-

After-sales Service Provided:

-

Online Support

-

Paper material:

-

3/5/7 ply corrugated cardboard

-

Speed:

-

150PCS/MIN

-

Suitable material:

-

3/5 layer corrugated cardboard paper board

Product Description

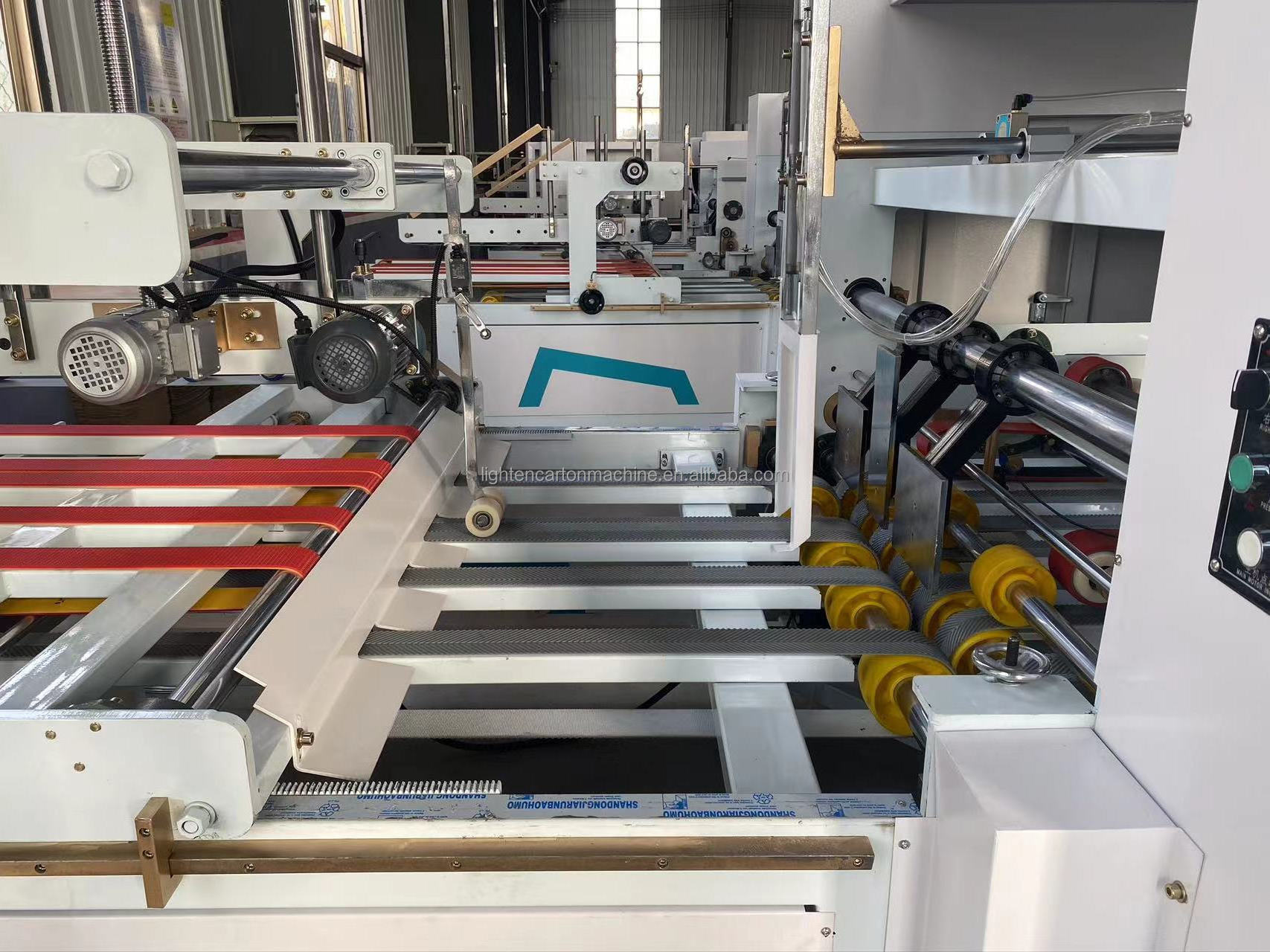

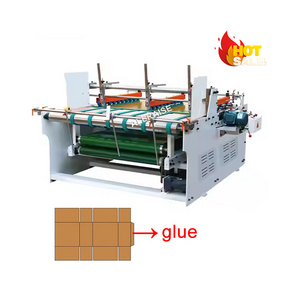

Automatic corrugated cardboard folding gluing strapping machine

This machine can achieve whole computer adjustment for feeder unit ,gluer unit and folder unit , just enter three data on the Touch Screen( Length, Width, Height size ) , the machine can automatic adjustment to the exact position.

Through PLC programme or adjustment button to setting ,which can meet any different operation habit.

The average speed of gluing box is 8000-10000pcs / hour, speed is very fast , greatly improve production efficiency.

This machine is the last process equipment of the carton folding, it is used to combination of 3 and 5 layer corrugated cardboard production line( if need to glue 7 layer cardboard, we also can produce according customers' appointed). Efficiency and production is attractive. The prominent advantage is low cost , strong adhesion, simple operating, saving labor and electric, runs smoothly, it is an ideal equipment for exporting advanced carton.

Product Paramenters

|

Model

|

QF- 2400

|

QF-2600

|

QF-2800

|

|

Max. feeding paperboard size (mm)

|

1200*2400

|

1400*2600

|

1400*2800

|

|

Min. feeding paperboard size (mm)

|

300*900

|

300 * 900

|

300 * 900

|

|

Power required

|

12 kw 380V 3phase 50HZ

|

12 kw 380V 3phase 50HZ

|

12 kw 380V 3phase 50HZ

|

|

Paperboard thickness

|

3 or 5 layer cardboard

|

3 or 5 layer cardboard

|

3 or 5 layer cardboard

|

|

Control way

|

PLC touch screen

|

PLC touch screen

|

PLC touch screen

|

|

Machine weight

|

5.5 tons

|

6.5 tons

|

6.5 tons

|

|

Dimensions

|

L11000 X W3000 X H1600

|

L12500 X W3200 X H1600

|

L12500 X W3400 X H1600

|

|

Max working speed

|

180m/min

|

180m/min

|

180m/min

|

Products Description

Feeding section

1:High quality and stability 8 feeding belts are made of Taiwan

2:Vacuum suction feeding system is good at adapting the curved paperboard

3:

Equipped with high quality electromagnetic clutch brake system, in order to control the feeding unit independently, which is good at reducing waste when changing order and improving the output precision.

The gluer section

1.Simple structure and high reliability, glue quantity adjustable, cleaning easily.

2. Stainless steel glue wheel adopted, long life and saving glue cost

2. Stainless steel glue wheel adopted, long life and saving glue cost

3.Improved quality rubber belt adopted, automatic folding.

4.with paperboard rectify device and creasing rectify device.

5.The Folder belts adopt Germany's force and Switzerland brand

4.with paperboard rectify device and creasing rectify device.

5.The Folder belts adopt Germany's force and Switzerland brand

Stacking section

1. Stacking and counting are simple and reliable.

2. Digital control, operation easily and reliable, No-stop put in data and automatic counting.

3. With rectification function.

4. Paperboard counting and put out by pneumatic, stable and quickly.

5. The machine functions by wireless remote control, carton size to adjust the speed quick, convenient.

2. Digital control, operation easily and reliable, No-stop put in data and automatic counting.

3. With rectification function.

4. Paperboard counting and put out by pneumatic, stable and quickly.

5. The machine functions by wireless remote control, carton size to adjust the speed quick, convenient.

6. Counter ejector section controls by touch screen, able to set up base carton number and push out carton number, working speed, production counting able to setup through touch screen.

Stripping unit

Automatic stripping ,high efficiency with corrugated cardboard bundling

All the machines used to control the motor contactor used Siemens AC contactor,

in line with the safe and reliable work.

Adopt color touch man-machine interface and master PLC control, convenient operation, strong humanity, HMI and master PLC are reserved for program upgrade interface, to facilitate the future use of equipment upgrades.

OUR COMPANY

Product packaging

Other machines

FAQ

1. Q: Are you a factory or trading company?

A: We are a company owned our factory which is specialized in the production of various kind of carton equipment. (With export license)

2. Q: How can I visit your factory?

A: We can pick you up if you need, welcome to visit our factory.

3. Q: What are your products?

A: We are specialized in producing 3ply, 5ply, 7ply corrugated cardboard production line, high speed printing machine, ordinary printing machine, creasing and die cutting

machine,folder gluer,flute laminator,stitching&strapping machine and other corrugated cardboard production equipments.

4. Q: How does your factory do regarding quality controlling?

A: Over the years our company take “the quality first” “integrity-based” corporate purpose always meet users’ requirements as our sole purpose, providing the products with excellent quality, professional technology. Always attach great importance to quality controlling from the very beginning to the very end.

a. All raw material we used are environmental-friendly.

b. Skillful workers care every detail in handling the producing and packing process.

c. Quality control department especially responsible for quality in each process.

5. Q: How is the evaluation of the products?

A: Products are distributed in Russia, the Middle East, Africa, Southeast Asia, EU and other countries and throughout the country. Product quality and enterprise reputation get the high praise at home and aboard.

6. Q: What is the payment term?

A: 30% deposit will be paid within 3 days after the contract is signed, and the remaining 70% will be paid before shipment.

Contact information

Hot Searches