- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Hongfa

-

Voltage:

-

220v or 380v

-

Power:

-

0kw

-

Dimension(L*W*H):

-

3600*1320*2800mm

-

Weight:

-

7600 kg

-

Features:

-

high capacity

-

Product Name:

-

precast concrete wall panel machine

-

Panel Thickness:

-

50mm, 60mm, 75mm, 90mm, 100mm, 120mm, 150mm

-

Machinery Making Wall Panel Size:

-

2440/3000*610;2440/3000*1220mm etc

-

Characteristics:

-

Discontinuous production

-

Color:

-

Client's Request

-

Raw material:

-

Polystyrene Foam(EPS), Additives, Fly Ash, Water,Panel,etc

-

Keywords:

-

Wall Panel Machine

-

Wall Panel Application:

-

Wall Partition, Internal and External Wall

-

Feature:

-

Soundproof, Environmental, Light Weight, Fireproof

-

Light Weight EPS Wall Panel:

-

550kg ---650kg/M3

Quick Details

-

Application:

-

for wall

-

Production Capacity:

-

58pcs for size 2440*610*60mm/per mould

-

Place of Origin:

-

Guangxi, China

-

Brand Name:

-

Hongfa

-

Voltage:

-

220v or 380v

-

Power:

-

0kw

-

Dimension(L*W*H):

-

3600*1320*2800mm

-

Weight:

-

7600 kg

-

Features:

-

high capacity

-

Product Name:

-

precast concrete wall panel machine

-

Panel Thickness:

-

50mm, 60mm, 75mm, 90mm, 100mm, 120mm, 150mm

-

Machinery Making Wall Panel Size:

-

2440/3000*610;2440/3000*1220mm etc

-

Characteristics:

-

Discontinuous production

-

Color:

-

Client's Request

-

Raw material:

-

Polystyrene Foam(EPS), Additives, Fly Ash, Water,Panel,etc

-

Keywords:

-

Wall Panel Machine

-

Wall Panel Application:

-

Wall Partition, Internal and External Wall

-

Feature:

-

Soundproof, Environmental, Light Weight, Fireproof

-

Light Weight EPS Wall Panel:

-

550kg ---650kg/M3

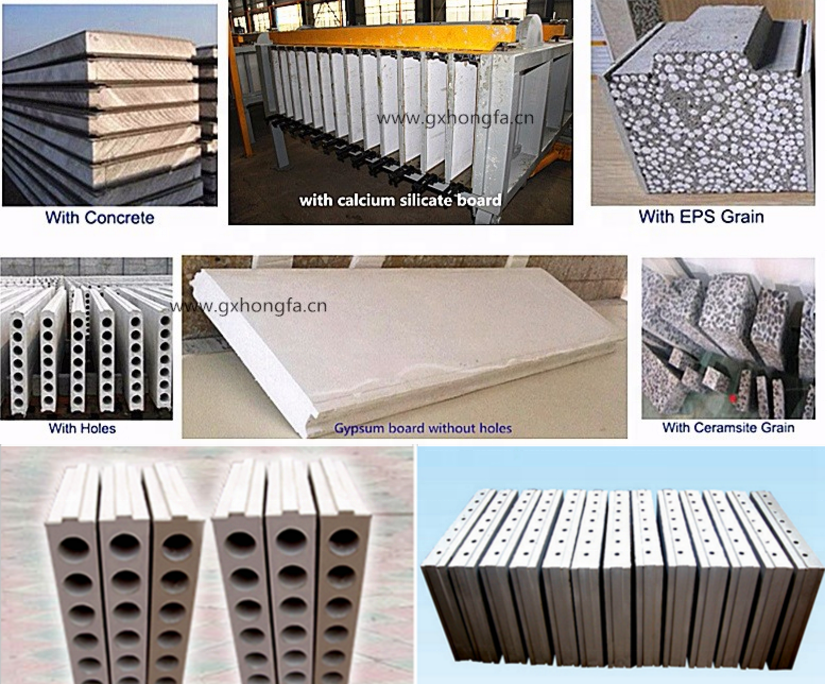

precast concrete wall panel machine precast concrete building molds foam concrete eps cement sandwich panel machine

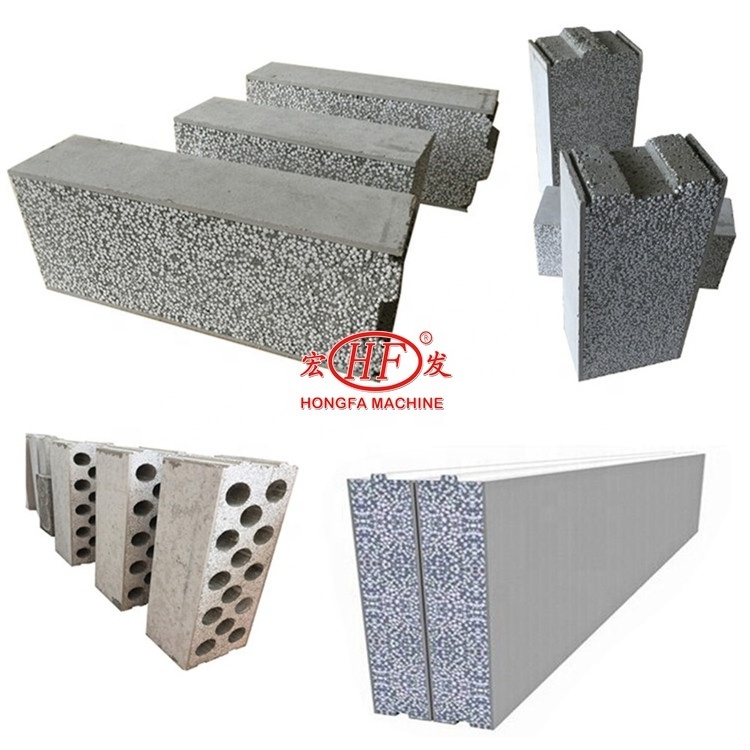

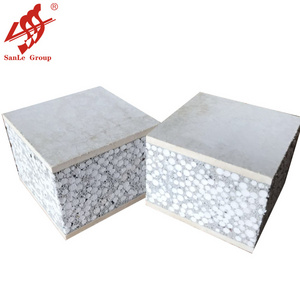

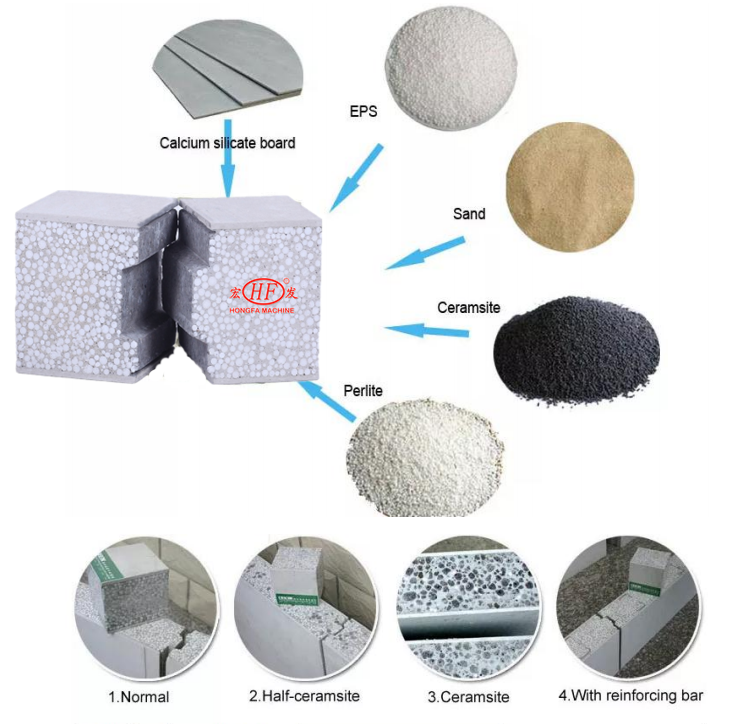

1. Materials of Hongfa Brand EPS Wall Panel

1) Outside (with side board or without)

- Calcium silicate board , Cement fiberboard. MGO board.

- Also can be without the side board and adjustable.

2) Inside (core material)

- Cement, Foam EPS ,Gypsum,

Fly Ash, Sand , Saw Dust, Perlite, Stone, Additives, etc.

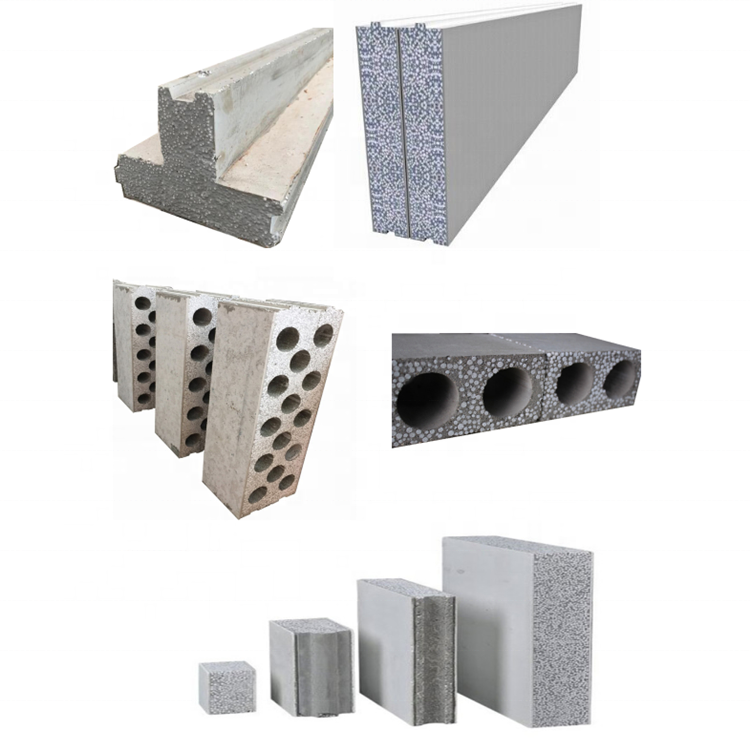

(B)Insulation Resistance: As this new wall panel is core of EPS insulation materials, which insulation performance is extremely advantageous and meet the building energy efficiency design standards, and rank first among similar products.

(C) Permeability Resistance: The bibulous rate of this new wall panel is only 3.3%,which has reached the international advanced level in the same industry.

(D) Fireproof performance: this kind of wall panel is non-burning, and according to the testing, it is reasonable fireproof materials, for the 90mm thickness wall panel, the fireproof performance can be more 3 hours.

(E) Soundproofing: As new wall panel is using EPS as core, it has good sound insulation and air aspiration, which is more than 40 db sound insulation.

The Hongfa Sandwich Lightweight EPS Cement Making Machine Features:

Most components of eps light weight wall panel making machine are of world-famous brands, with reliable performance, stable quality, long service life and low maintenance cost.

Advantage of our wall panel machine

2. ISO9001-2015

3. Easy to maintainence, Easy to clean.

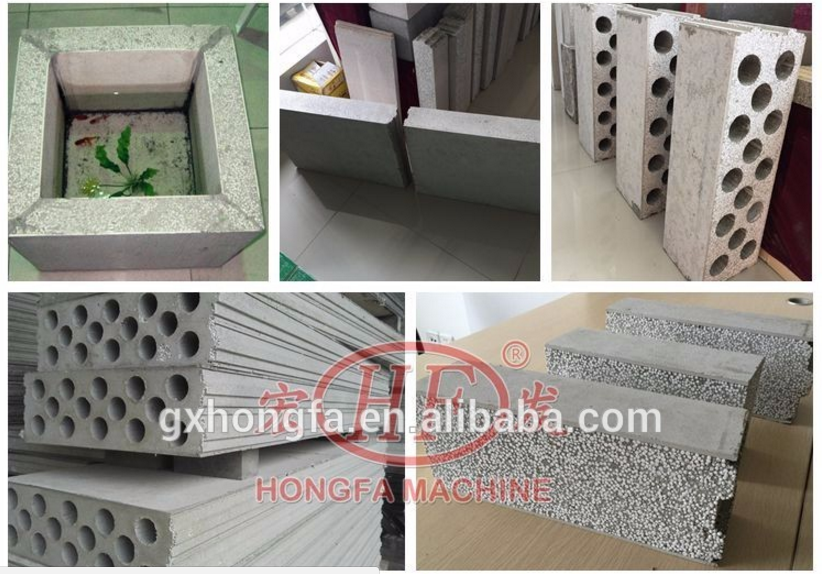

Applied range of light weight EPS wall panel

Our Services

1: Horizontal type EPS wall board forming machine: high level of automatic operation,fewer workers required.

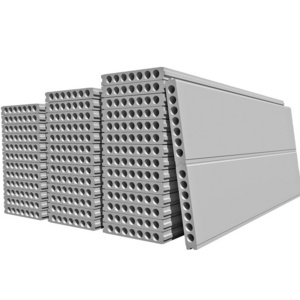

| Horizontal Type | |||||||

| Overall dimensions | Power | Output with different thickness/pieces per mold | |||||

| 60mm | 75mm | 90mm | 100mm | 120mm | 150mm | ||

| 2750x2504x1359 mm | 3kw | 16pcs | 14pcs | 12pcs | 12pcs | 10pcs | 8pcs |

2: Automatic vertical type: automatic operation,high output,fewer workers required.

| Automatic Vertical Type | |||||||

| Overall dimensions | Power | Output with different thickness/pieces per mold | |||||

| 60mm | 75mm | 90mm | 100mm | 120mm | 150mm | ||

| 3380x3200x2680 mm | 4kw | 40pcs | 36pcs | 32pcs | 30pcs | 26pcs | 22pcs |

| Manual Vertical Type | |||||||

| Overall dimensions | Power | Output with different thickness/pieces per mold | |||||

| 60mm | 75mm | 90mm | 100mm | 120mm | 150mm | ||

| 3600x1320x2800 mm | no | 58pcs | 50pcs | 42pcs | 40pcs | 34pcs | 28pcs |

Successful Plant

Package & Delivery

Packing: Naked packing or stretch film packing or according to customers' requirements

Delivery time: Within 40 days after receipt of deposit and moulds confirmation from buyer