Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Office Building

-

Design Style:

-

Industrial

-

Weight:

-

customized

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HENGER

-

Model Number:

-

HE-DC

-

Product name:

-

Good quality 304 Stainless steel floor drain cover

-

Main Material:

-

SUS304 stainless steel

-

Certification:

-

ISO9001

-

Usage:

-

Drainage System

-

MOQ:

-

50pcs

-

Advantage:

-

Anti-odour,heavy duty

-

Feature:

-

Corrosion-Resistant

-

Delivery time:

-

25-30days

-

Keyword:

-

floor drain

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support, Onsite Inspection, Free spare parts

-

Project Solution Capability:

-

3D model design, Cross Categories Consolidation

-

Application:

-

Office Building

-

Design Style:

-

Industrial

-

Weight:

-

customized

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HENGER

-

Model Number:

-

HE-DC

-

Product name:

-

Good quality 304 Stainless steel floor drain cover

-

Main Material:

-

SUS304 stainless steel

-

Certification:

-

ISO9001

-

Usage:

-

Drainage System

-

MOQ:

-

50pcs

-

Advantage:

-

Anti-odour,heavy duty

-

Feature:

-

Corrosion-Resistant

-

Delivery time:

-

25-30days

-

Keyword:

-

floor drain

Product Description

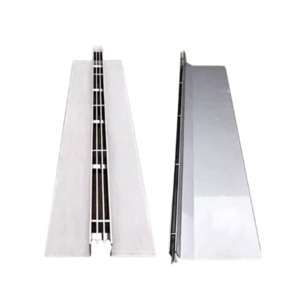

Hot sale 304 Stainless Steel Drainage Cover Drain Grates Trench Drain Cover

Drainage system include gutterway and cover .

The main function

is to collect waste water and transport it from the pipeline to the underground drainage ditch to prevent malodor or other substances from entering. Three-layer filtering device can reduce the risk of blockage and remove blockage. Urban drainage system can reduce the impact of rainfall or other water flow on buildings

Main Feature

1. 304 stainless steel, Long lifetime;

2.Circular arc design, 360 degree no dead angle, easy to clean design;

3.Removable deodorization core inside,water seal to keep clear water, no pollution and no odor

4.Can be designed according to the customer's factory area;

Main Feature

1. 304 stainless steel, Long lifetime;

2.Circular arc design, 360 degree no dead angle, easy to clean design;

3.Removable deodorization core inside,water seal to keep clear water, no pollution and no odor

4.Can be designed according to the customer's factory area;

Details Images

|

Product Name

|

304 Stainless Steel Drainage Trench Grating

|

|

Type

|

Square Floor drain

|

|

Material

|

304 Stainless steel

|

|

Size

|

10/15/20/25//30/35/40 *58*2.5cm

|

|

Features

|

Anti-odour

|

|

Project solution capacity

|

Graphic design, 3D model design, total solution for projects

|

|

The field of application

|

Workshop/Hospital/ Office building/Food factory

|

Workshop

Design Requirements for Drainage Ditch

1. The drainage of the workshop should be considered comprehensively with the drainage of the plant

.

Different water ditches are used in different cleaning areas. For general cleaning areas and quasi-cleaning areas, open ditches are covered with stainless steel side rails. Hidden ditch must be made in high clean area.The indoor drainage (including floors) of the production workshop should be an open ditch without cover, and the open ditch should have a certain width (200~300mm), depth (150~400mm) and slope

(greater than 1%), and the drainage slope of the workshop floor Should be 1.5~2%

(greater than 1%), and the drainage slope of the workshop floor Should be 1.5~2%

2. The water pipeline should maintain a certain slope and flow from the clean area to the unclean area.

The flow of sewage flows from the high clean area to the low clean area. Design a certain slope to avoid pollution caused by dirty water discharge. The slope of the main drainage pipe in the workshop should consider the location of the drainage outlet, its location and the slope of the main drainage pipe in the workshop should also consider the depth of the drainage pipe under the drainage outlet of the workshop and the reasonable location of the drainage ditch depth in the plant area.

The flow of sewage flows from the high clean area to the low clean area. Design a certain slope to avoid pollution caused by dirty water discharge. The slope of the main drainage pipe in the workshop should consider the location of the drainage outlet, its location and the slope of the main drainage pipe in the workshop should also consider the depth of the drainage pipe under the drainage outlet of the workshop and the reasonable location of the drainage ditch depth in the plant area.

3. The drainage pipeline should be leveled during construction.

There must be no unevenness and cracks to ensure the smooth drainage of the workshop, and there must be a certain arc at the turning point

Packing&Shipping

Related Equipment

FAQ

1) When can I get the price?

Our machines are all high-end customized products, after we understand all your needs, we will make a complete quotation for you.

2) How do you make your price?

We are a manufacturer rather than a trading company. We can be responsible to customers and machines and provide you with a more

competitive price.

3) Can you guarantee your quality?

We purchase parts and raw materials produced by famous brand manufacturers, which can effectively guarantee the quality of the

machine.

4) How long does the whole procedure being worked out?

The production cycle of the machine is 20-45 days, and we will calculate the production cycle required to make the machine for you

according to the drawings designed for you.

5) What about the transportation and delivery date?

The way of transporting goods is usually ocean shipping .The time required for sea transportation is usually 10-45 days.We will do

our best to deliver goods to you safely and in time.

Our machines are all high-end customized products, after we understand all your needs, we will make a complete quotation for you.

2) How do you make your price?

We are a manufacturer rather than a trading company. We can be responsible to customers and machines and provide you with a more

competitive price.

3) Can you guarantee your quality?

We purchase parts and raw materials produced by famous brand manufacturers, which can effectively guarantee the quality of the

machine.

4) How long does the whole procedure being worked out?

The production cycle of the machine is 20-45 days, and we will calculate the production cycle required to make the machine for you

according to the drawings designed for you.

5) What about the transportation and delivery date?

The way of transporting goods is usually ocean shipping .The time required for sea transportation is usually 10-45 days.We will do

our best to deliver goods to you safely and in time.

Contact Us

Hot Searches