- Product Details

- {{item.text}}

Quick Details

-

Ejector Force(kN):

-

50 kN

-

Theoretical Shot Volume(cm³):

-

318 cm³

-

Injection Rate (g/s):

-

132 g/s

-

Injection Weight (g):

-

289 g

-

Screw diameter (mm):

-

45 mm

-

Weight (KG):

-

4000 kg

-

Place of Origin:

-

China

-

Open Stroke(mm):

-

380 mm

-

Power (kW):

-

13 kW

-

Plastic Type:

-

Thermoplastic

-

Automatic:

-

Yes

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Injection Screw diameter:

-

38-45mm

-

Screw L/d ratio:

-

22.1-18.6

-

screw speed:

-

190

-

Max mould height:

-

450 mm

-

Min mould height:

-

160 mm

-

Ejector stroke:

-

120 mm

-

Ejector force:

-

50 kn

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

420mm

-

Distance between Tie Bars(Height)(mm):

-

420mm

-

Ejector Stroke(mm):

-

120 mm

-

Ejector Force(kN):

-

50 kN

-

Theoretical Shot Volume(cm³):

-

318 cm³

-

Injection Rate (g/s):

-

132 g/s

-

Injection Weight (g):

-

289 g

-

Screw diameter (mm):

-

45 mm

-

Weight (KG):

-

4000 kg

-

Place of Origin:

-

China

-

Open Stroke(mm):

-

380 mm

-

Power (kW):

-

13 kW

-

Plastic Type:

-

Thermoplastic

-

Automatic:

-

Yes

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Injection Screw diameter:

-

38-45mm

-

Screw L/d ratio:

-

22.1-18.6

-

screw speed:

-

190

-

Max mould height:

-

450 mm

-

Min mould height:

-

160 mm

-

Ejector stroke:

-

120 mm

-

Ejector force:

-

50 kn

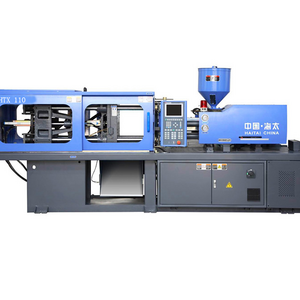

1 . SPECIFICATIONS

Strong Technical design ability, Stable quality, and large production capability,

Famous brand.

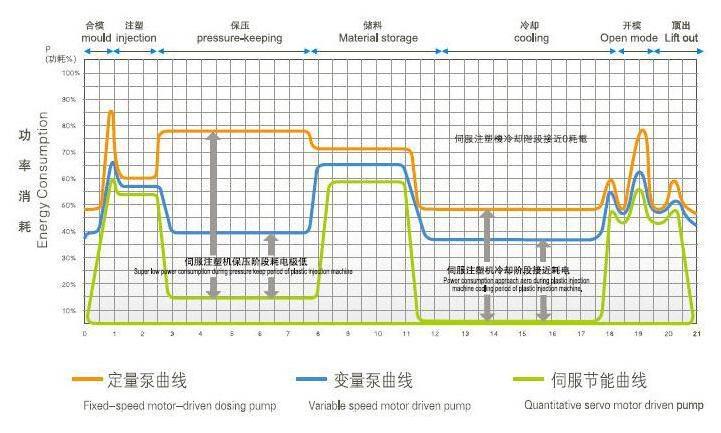

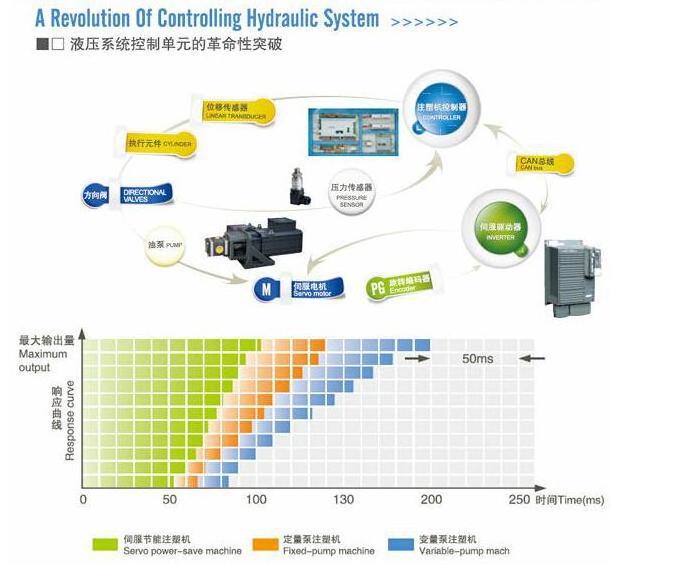

HTW/JD servo energy saving Injection Molding Machine, equipped with high performance servo motor

controlling system, the machine's output power can vary in accordance with the loading changes, which reduce energy consumption and noise. The motor rotates at lower speed in holding pressure stage, and doesn't work in cooling time.

The Performance of servo energy-saving molding machine:

- Servo motor can optimize the match of energy demand and realize automatic adjustments.

- It can improve injection precision

- It can greatly save power and water, resulting in environment-protection and energy-saving

- Quick response and low noise.

2 . TECHNICAL PARAMETERS

|

SPECIFICATION

|

HTW140

|

|||

|

A

|

B

|

C

|

||

|

INJECTION UNIT

|

||||

| Screw diameter | mm |

38

|

42

|

45

|

| Screw L/D ratio | L/D |

22.1

|

20

|

18.6

|

| Shot volume(theoretical) | cm3 |

193

|

235

|

270

|

| Injection weight(ps) | g |

176

|

213

|

246

|

| Injection rate | g/s |

94

|

115

|

132

|

| Injection pressure | Mpa |

205

|

170

|

147

|

| Screw pressure | rpm |

190

|

||

|

CLAMPING UNIT

|

|

|||

| Clamping force | kN |

1400

|

||

| Open stroke | mm |

380

|

||

| Space between tie bars(W×H) | mm |

410×410

|

||

| Max.Mold height | mm |

450

|

||

| Min.Mold height | mm |

160

|

||

| Ejector stroke | mm |

120

|

||

| Ejector force | kN |

50

|

||

|

OTHERS

|

|

|||

| Max.Pump pressure | MPa |

16

|

||

| Pump motor power | kW |

13

|

||

| Heating power | kW |

7.9

|

||

| Machine dimension(L×W×H) | m |

4.48×1.11×1.9

|

||

| Oiltank cubage | L |

270

|

||

| Machine weight | t |

4.0

|

||

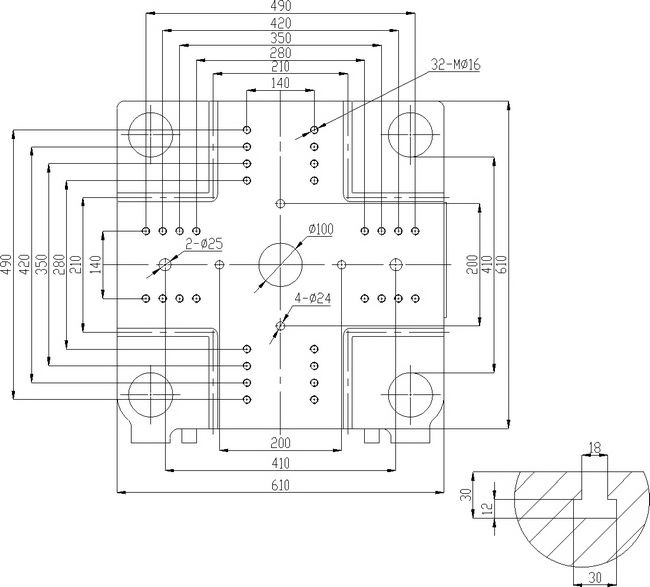

| PLATEN DIMENSIONS |

|

| MOULD SPACE DIMENSOINS |