- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Dingchen

-

Voltage:

-

380V 50HZ

-

Power:

-

4--8kw

-

Dimension(L*W*H):

-

3200mm*1000mm*1800mm

-

Weight:

-

1000 kg

-

Warranty:

-

1 Year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Speed:

-

0--900 sheets/min

Quick Details

-

Production Capacity:

-

Other

-

Processing Type:

-

paper converting machine

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Dingchen

-

Voltage:

-

380V 50HZ

-

Power:

-

4--8kw

-

Dimension(L*W*H):

-

3200mm*1000mm*1800mm

-

Weight:

-

1000 kg

-

Warranty:

-

1 Year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Speed:

-

0--900 sheets/min

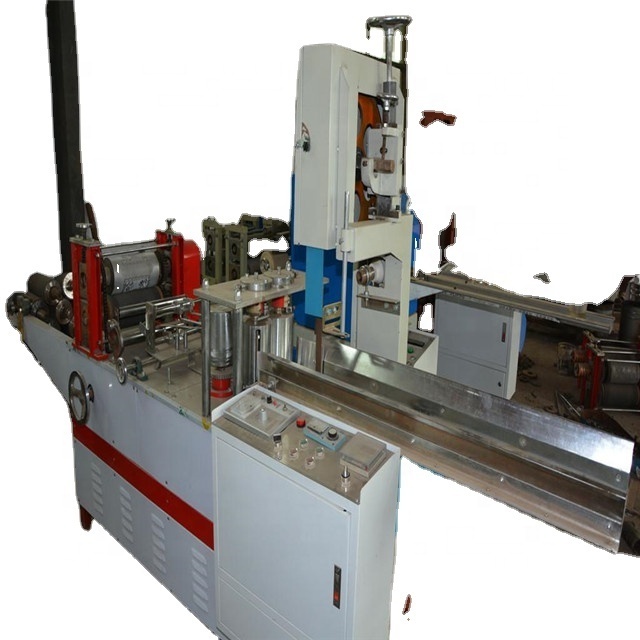

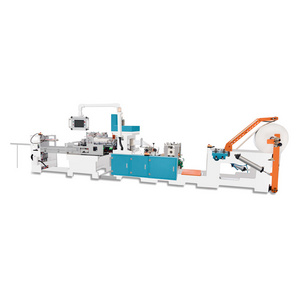

Napkin paper/tissue paper folding machine

Produc description:

High spped machine is used for raw plate paper napkin after embossing, folding, cutting and processing, electronic counting into a square napkin, in the production process of automatic embossing without manual folding, folding, flower type other napkins according to the flower pattern of users need to make different clear beautiful.

Product features:

1.Automatic counting, the whole column, convenient pakaging

2.The production speed, low noise, suitable for household production.

3.According to user requirements for the manufacture of a variety of different specifications of the models.

4.Can increase the function of synchronous transmission and automatic shutdown of paper cutting function, higher security, faster production (customized)

Technical parameter

|

Model |

DC--A |

|

Open size (mm) |

180mm*180mm--460mm*460mm |

|

Folded size (mm) |

90mm*90mm--230mm*230mm |

|

Paper Roll diameter |

≤Φ1 3 00 mm |

|

Capacity |

800 pcs/min |

|

Paper roll inner diameter (mm) |

750mm standard ( can appoint another spec ) |

|

Embossing roll |

yes |

|

Counting system |

Electricity |

|

Power |

4kw |

|

Dimension size (mm) |

3 8 00 x 1 4 00x1 75 0mm |

|

Weight |

1 3 00kg |

|

Transmission |

6# chain |

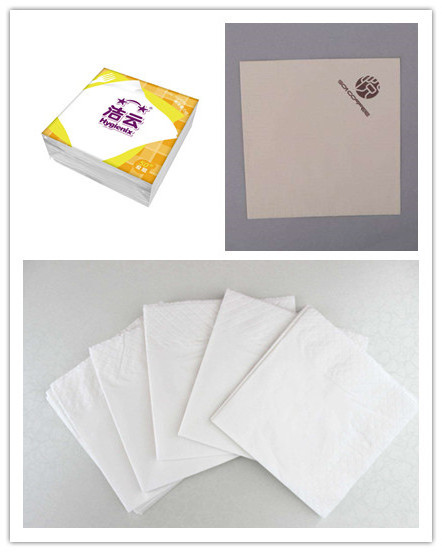

Finished Product

We can integrate with a very deep experience on the Turn-Key basis.

1. Customized projects and complete production lines designed according to customer needs.

2. Modification of existing machines with solutions to satisfy customer needs.

3. The machine can be supplied with the accessories using first class components.

4. We shall provide the drawing, foundation drawing and layout drawing after receiving the advance payment.

5. We have the professional installation team to provide erection/or erection supervision, commissioning, test-run and training for customer. The customer shall provide international flight ticket, local transportation vehicle, food, hotel accommodations and salary for our engineers.

6. Performance and Mechanical Guarantee shall be provided for 1 year from the successful commissioning