- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1950*1050*2750

-

Weight:

-

1100 KG

-

Marketing Type:

-

Hot Product 2023

-

Name:

-

oil press machine

-

Product name:

-

cooking oil automatic pressing machine

-

Keyword:

-

oil pressing machines saro zambia

-

Keyword 2:

-

20 kilo olive oil pressing machine

Quick Details

-

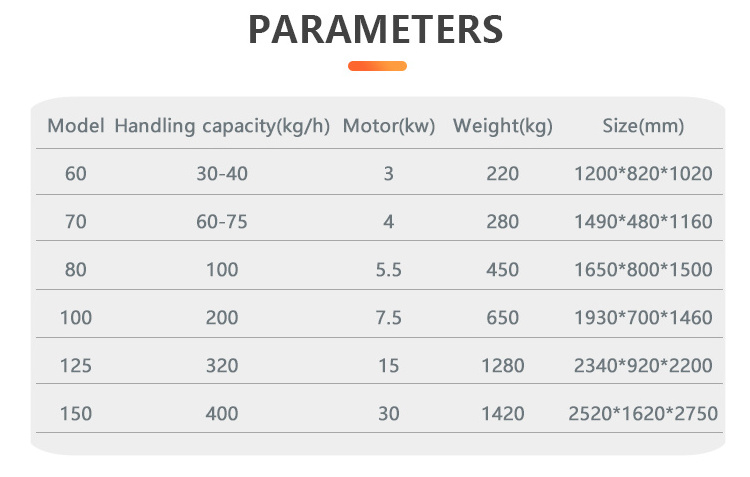

Production Capacity:

-

800KG/H

-

Place of Origin:

-

zheng zhou

-

Voltage:

-

380/220V

-

Dimension(L*W*H):

-

1950*1050*2750

-

Weight:

-

1100 KG

-

Marketing Type:

-

Hot Product 2023

-

Name:

-

oil press machine

-

Product name:

-

cooking oil automatic pressing machine

-

Keyword:

-

oil pressing machines saro zambia

-

Keyword 2:

-

20 kilo olive oil pressing machine

saro zambia 20 kilo cooking olive oil automatic pressing machine

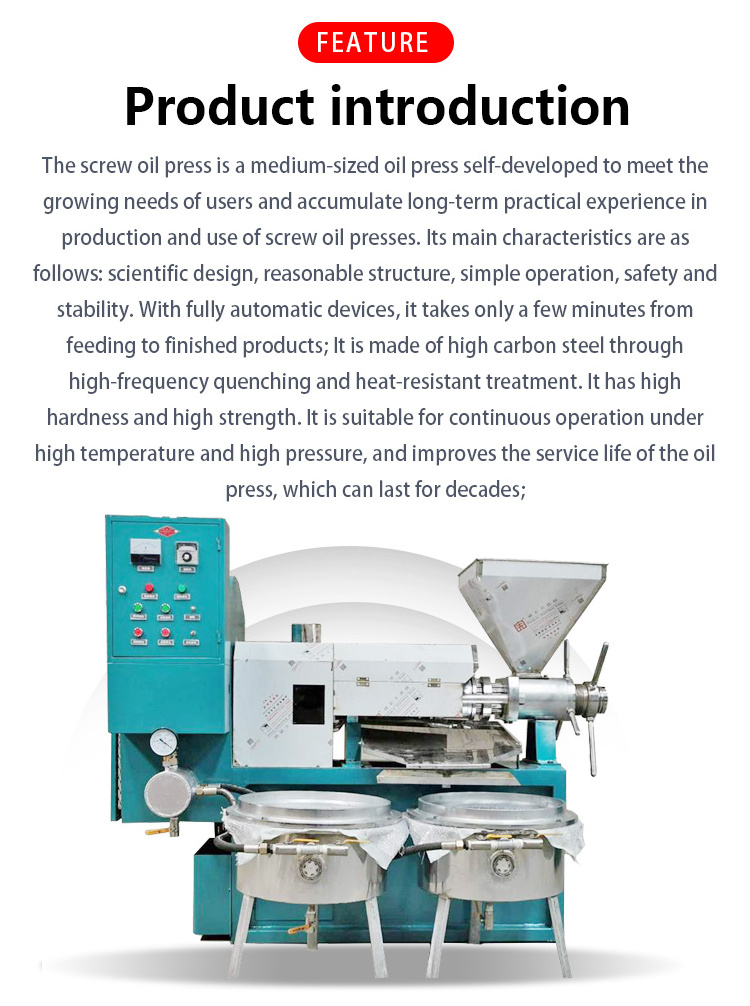

Operating principle of oil press

After the oil press is started up, the power is transmitted to the main shaft after being decelerated. The screw on the main shaft rotates and pushes the oil between the threads forward. As the space between the chamber and the screw is gradually reduced, the density of the oil increases, and the pressure gradually increases. During the pressing process, the friction between oil particles and between oil and parts generates heat. In this way, pressure and heat constitute two major elements of the oil extraction process, which destroy the oil tissue cells, oil overflows from the oil line, and the cake is pushed out from between the cake head and the outlet. When the pressed oil flows into the oil filter, press the vacuum pump button, the vacuum pump starts to operate, the air in the oil filter barrel is pumped out, the negative pressure is formed in the barrel, the oil on the barrel naturally flows into the oil filter barrel, and the oil residue is isolated on the filter cloth. After the pressing is completed and the oil is pumped out, stop the vacuum pump operation, open the valve on the oil filter barrel, the dry residue on the filter cloth is formed, and scrape it off with a scraper, The oil in the oil filter can be drained from the valve at the bottom of the oil drum. At this time, pure oil is obtained.

cooking oil automatic pressing machine oil pressing machines saro zambia 20 kilo olive oil pressing machine

Features of screw oil press:

The disadvantages of the traditional oil extraction method: original workshop, simple equipment, heavy operation, large floor area, high energy consumption, low oil yield, and poor sanitary environment.

Dingsheng energy saving, design, beautiful appearance, reliable performance, simple operation and convenient maintenance. High oil output rate - compared with the old equipment, the normal oil output rate can be 4-6 percentage points higher, and the average oil output per 100 kg of peanut can be 4-6 kg more. The annual economic benefits are very considerable.

Energy saving - reduce the power by 40% with the same output. Based on the average saving of 6 kilowatt-hours per hour, the daily production can save 30 yuan of electricity. Labor saving - 60% of labor can be saved in the same output. One to two people can organize production, and the labor efficiency cost can be saved by about 40 yuan per day.

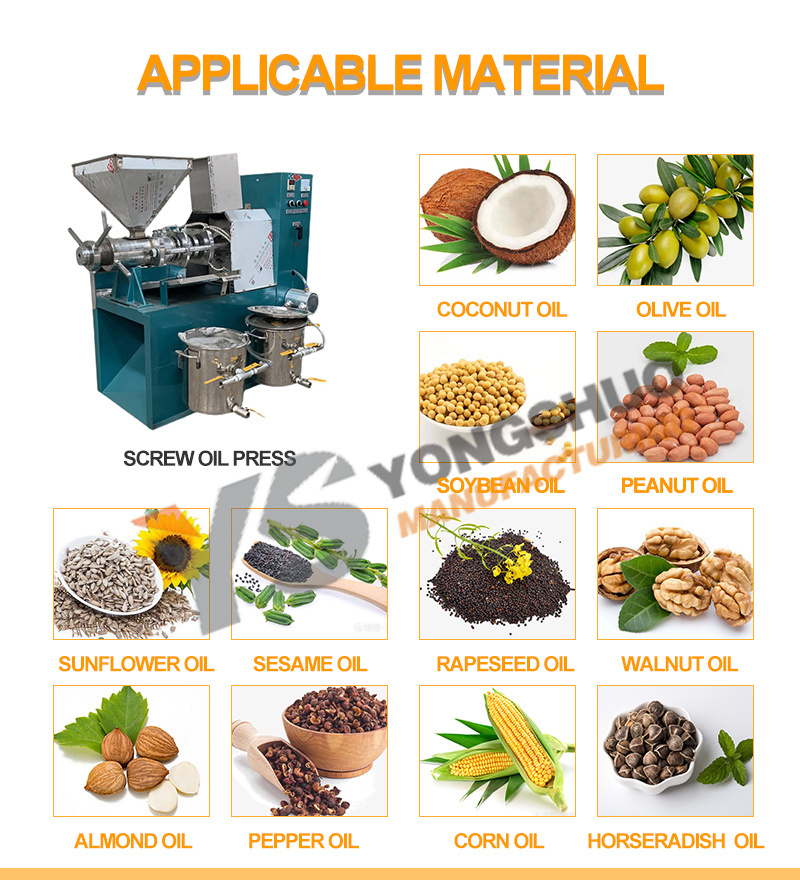

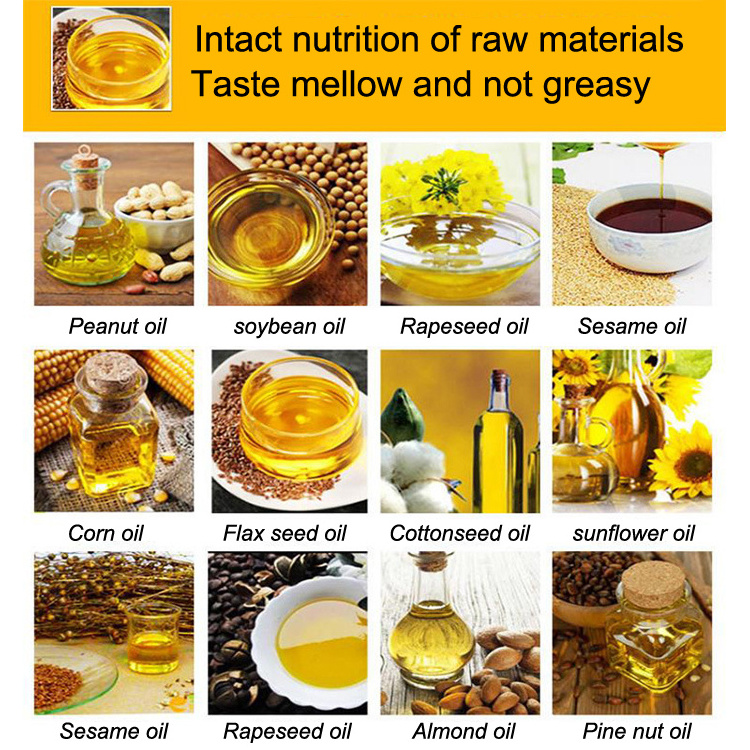

It can be used for a wide range of purposes. It can press more than 20 kinds of oil crops, such as peanut, sesame, rapeseed, cottonseed, soybean, etc. Multi-stage press, one press. Pure oil quality - vacuum filtration residual inspection, to ensure that the oil quality is pure and meet the health and quarantine standards.

The oil workshop covers a small area of 10-20 square meters and can be used.

cooking oil automatic pressing machine oil pressing machines saro zambia 20 kilo olive oil pressing machine