Mullite bricks are high alumina refractories with mullite as the main crystal phase. Generally, the alumina content is between 65% and 75%, and the refractory of mullite brick is relatively high, reaching above 1790 ℃. The starting temperature of load softening is 1600 ~ 1700 ℃. Good thermal shock resistance. There are two kinds of sintered mullite bricks and fused mullite bricks.Standard size 230 x 114 x 65 mm or according to customer requirements.

- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

Customizable

-

CrO Content (%):

-

Customizable

-

SiC Content (%):

-

Customizable

-

Place of Origin:

-

Henan, China

-

Model Number:

-

Mullite Brick

-

Brand Name:

-

Rongsheng Refractory

-

Product name:

-

Mullite bricks refractory

-

Application:

-

Industrial Furnaces

-

Type:

-

Raw Refractory

-

Size:

-

Customized Size

-

Certificate:

-

ISO9001

-

Advantage:

-

High Thermal Stability

-

Usage:

-

Fire Resistance Place

-

Sample:

-

Provide

-

Feature:

-

High Temperature Resistant

-

Raw material:

-

high pure mullite

Quick Details

-

SiO2 Content (%):

-

≤ 35%

-

Al2O3 Content (%):

-

≥ 65%

-

MgO Content (%):

-

Customizable

-

CaO Content (%):

-

Customizable

-

CrO Content (%):

-

Customizable

-

SiC Content (%):

-

Customizable

-

Place of Origin:

-

Henan, China

-

Model Number:

-

Mullite Brick

-

Brand Name:

-

Rongsheng Refractory

-

Product name:

-

Mullite bricks refractory

-

Application:

-

Industrial Furnaces

-

Type:

-

Raw Refractory

-

Size:

-

Customized Size

-

Certificate:

-

ISO9001

-

Advantage:

-

High Thermal Stability

-

Usage:

-

Fire Resistance Place

-

Sample:

-

Provide

-

Feature:

-

High Temperature Resistant

-

Raw material:

-

high pure mullite

Products Description

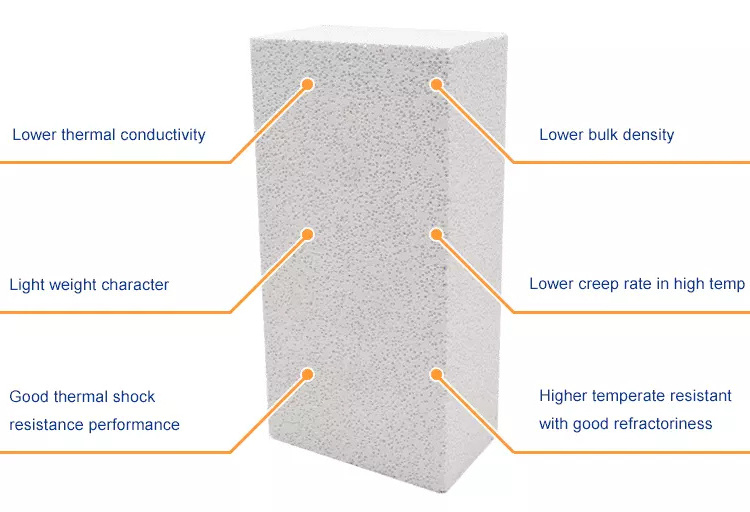

Product Features

It has the advantages of high porosity, small bulk density, good insulation effect, and long service life. With high refractoriness, mullite insulation bricks can be directly exposed to flames. They have the characteristics of light weight, high strength, low thermal conductivity, good thermal shock resistance.For various industrial kilns, it is an important energy-saving, insulation, and refractory material.

1. Good integrity with furnace lining, long service life, easy operation, could be shaped freely

2. Product specification: standard form, normal standard, shaped and special shaped bricks.

3. Can be used in various kilns because of its cheapness and general tray package. Among all of the refractory materials, it is the most widely used.

Product Application

Mainly used for hot blast furnace top, blast furnace stack and bottom, glass furnace regenerator, ceramic sintering kiln, dead corner lining of petroleum cracking system,ethylene pyrolysis furnaces, tubular furnaces,reforming furnaces of synthetic ammonia,gas generators,linings or heat-insulating materials of the industries,etc.

1. Furnaces of metallurgy industry, heat treatment furnace

2. Furnaces of chemical industry and construction industry.

3. Furnace of incineration of garbage, recirculating fluidized bed furnace

Product Paramenters

|

Mullite Bricks

|

|

|

|

|

|

|||||

|

Item

|

|

MU 60

|

MU 65

|

MU 70

|

MU 75

|

|||||

|

|

Al2O3

|

≥60

|

≥65

|

≥70

|

≥75

|

|||||

|

|

SiO2

|

≤35

|

≤33

|

≤26

|

≤24

|

|||||

|

|

Fe2O3

|

≤1.0

|

≤1.0

|

≤0.6

|

≤0.4

|

|||||

|

Bulk Density g/cm3

|

|

≥2.55

|

≥2.55

|

≥2.55

|

≥2.55

|

|||||

|

Permanent Linear Change On Reheating (%) 1500℃X2h

|

|

0~+0.4

|

0~+0.4

|

0~+0.4

|

0~+0.4

|

|||||

|

Apparent Porosity %

|

|

≤17

|

≤17

|

≤17

|

≤18

|

|||||

|

Thermal Conductivity (W/MK) 1000℃

|

|

1.74

|

1.84

|

1.95

|

1.95

|

|||||

|

Cold Crushing Strength Mpa

|

|

≥60

|

≥60

|

≥80

|

≥80

|

|||||

|

Thermal Expansion coefficient 10-6/℃

|

|

0.6

|

0.6

|

0.6

|

0.55

|

|||||

|

0.2Mpa Refractoriness Under Load T0.6 ℃

|

|

≥1580

|

≥1600

|

≥1600

|

≥1650

|

|||||

|

Thermal Shock Resistances 1000℃ water cycles

|

|

≥18

|

≥18

|

≥18

|

≥18

|

|||||

Our Advantages

Zhengzhou Rongsheng Import And Export Co., Ltd.

Our company is located in Henan, China. Our company has professional scientific and technical personnel and production team, and we have our own fully automated factories. For more than ten years, we have focused on the development and innovation of refractory materials and high-temperature furnace technology, and strive to provide customers with comprehensive, personalized and

cost-effective services with high-quality products. Our products are widely used in electric power, metallurgy, petrochemical and

other fields, and are exported to more than 70 countries and regions in the world such as Europe, America, Oceania, Southeast Asia, and the Middle East.

Zhengzhou Rongsheng Import And Export Co., Ltd. is a first-class supplier of refractory materials, we can provide you with the

most advantageous quotations and products. Looking forward to be your partner!

FAQ

Q1.

Are you Manufacturer?

A:

Yes, of course, our factory is in Xinmi, zhengzhou city, Henan province.

Q2. Can we visit your company?

A: Sure,welcome at any time, seeing is believing.

Q3. Do you accept OEM?

A: Yes, we can do OEM.

Q4. What's the MOQ of trial order?

A: No limit, we can offer the best suggestions and solutions according to your condition.

Q5. What are the payment terms?

A: Usually T/T, but L/C, Western Union etc are available for us.

Q6. How long is delivery time?

A: The delivery time usually depends on the order quantity, usually around 7-12 days.

Recommend Products

Hot Searches