- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

RD

-

Finished size (mm):

-

customizable

-

Roll width (mm):

-

250-650

-

Roll diameter (mm):

-

290-1000

-

Pressure type:

-

Inclined iron constant pressure/hydraulic type

-

Main engine Power (KW):

-

7.5-132

-

Raw material:

-

Charcoal Powder

-

Product name:

-

Brequitte Making Machine

-

Briquette shape:

-

Customer's Demand

-

Application:

-

Heating Cooking BBQ

-

MOQ:

-

1 Set

Quick Details

-

Weight (KG):

-

1600

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

RD

-

Finished size (mm):

-

customizable

-

Roll width (mm):

-

250-650

-

Roll diameter (mm):

-

290-1000

-

Pressure type:

-

Inclined iron constant pressure/hydraulic type

-

Main engine Power (KW):

-

7.5-132

-

Raw material:

-

Charcoal Powder

-

Product name:

-

Brequitte Making Machine

-

Briquette shape:

-

Customer's Demand

-

Application:

-

Heating Cooking BBQ

-

MOQ:

-

1 Set

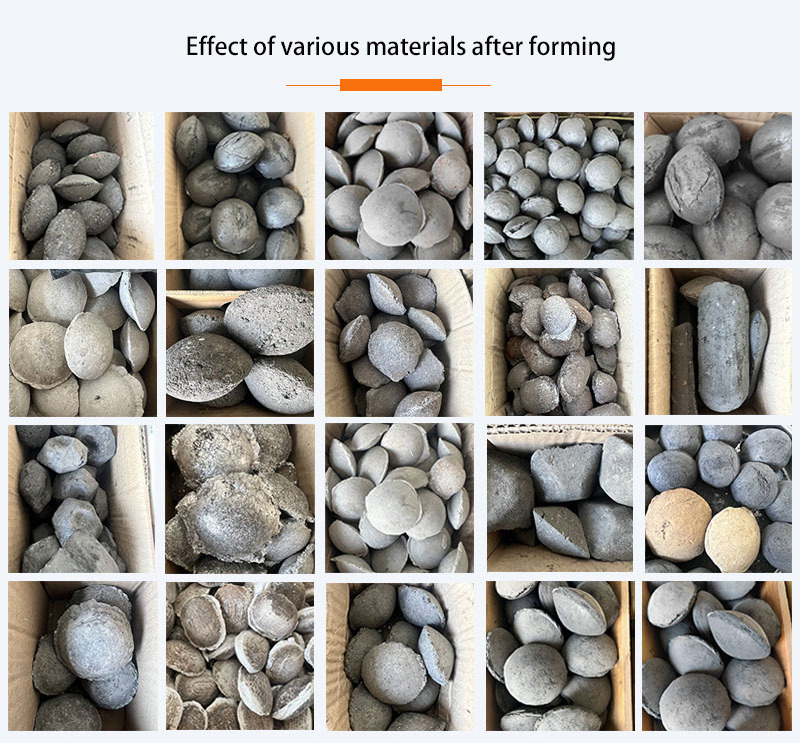

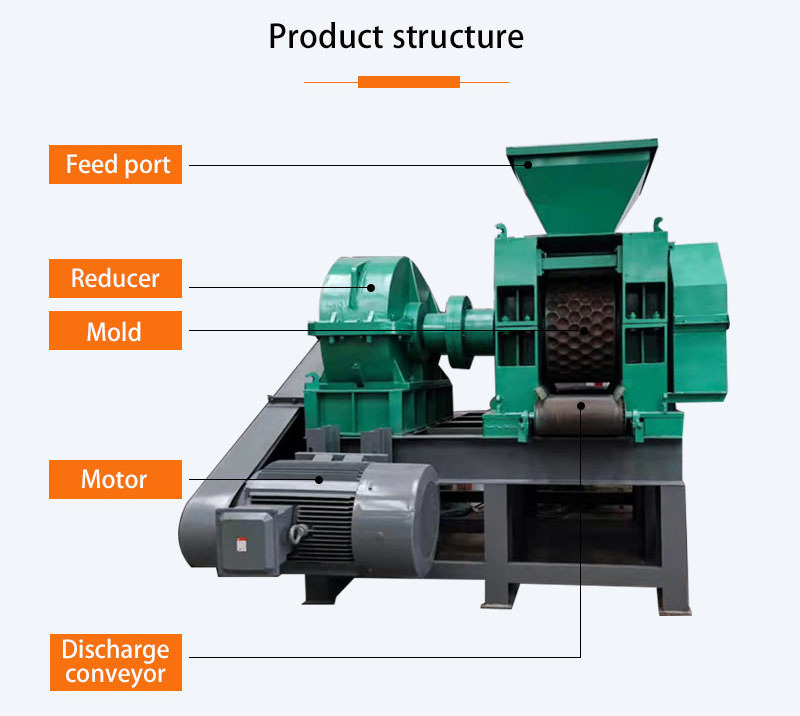

Steel Slag Ball Press Machine Lignite Fluorite Ore Metal Powder Ball Press Machine Coke Dust Powder Ball Press Machine

The briquetting press is also known as briquetting machine, briquette making machine, coal briquette machine, ball press, or briquette press, but in China people always call it briquette machine. This coal briquette machine is mainly used for various mining material, metallurgical materials , industrial wastes etc, such as coal, coal slurry, bitumite, lignite, brown coal, coke powder, steel slag, bag filters dust, furnace flue dust , manganese, mill scales, carbon black...The all materials in different industries needed to be smelted in kiln shall be completed by coal slime briquetting machine.

Widely used in refractory, power plant, metallurgy, chemical industry, energy, transportation, heating and other industries, the material after molding by the ball press, energy saving and environmental protection, easy to transport, improve the utilization rate of waste materials, has good economic and social benefits.

NOTE:

1. No metal objects are allowed in the material, otherwise the surface of the roller skin will be damaged.

2. Before feeding, be sure to fill the material after several weeks of empty operation of the machine. To prevent the ball press machine to eat too much material, causing overload to the reducer and the motor, so that the ball press roller shaft is broken.

3. Any change of technical data shall not be advised additionally.

Before leaving the factory, the products will undergo strict testing. After professional packaging, the products will be delivered by the best route or the route designated by customer.

1. Install waterproof membrane to reduce dust and water pollution.

2. Standard wooden boxes are used as outer packaging to reduce bumps in international transportation.