- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

500

-

Weight (KG):

-

890 KG

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Duan Yue

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

3.5 kW

-

Product name:

-

Fixed vacuum emulsifying homogenizing mixer

-

Heating method:

-

Electric / Steam Heating

-

Motor:

-

Siemens Motor

-

Layer:

-

2-3 Layers

-

Machine Type:

-

Dispersion Blender Mixer Machine

-

Control:

-

PLC+ Touch Screen / Button control

-

Homogening speed:

-

0-3600 R/min

-

Stirrer typ:

-

High Speed Homogenizer

-

Advantage:

-

Longer Shelf Life

-

Capacity:

-

50L-2000L

Quick Details

-

Barrel Volume (L):

-

500L

-

Max. Loading Volume (L):

-

500 L

-

Range of Spindle Speed(r.p.m):

-

1 - 63 r.p.m

-

Max. Loading Capacity:

-

500

-

Weight (KG):

-

890 KG

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Duan Yue

-

Voltage:

-

Customized

-

Dimension(L*W*H):

-

Customized

-

Power (kW):

-

3.5 kW

-

Product name:

-

Fixed vacuum emulsifying homogenizing mixer

-

Heating method:

-

Electric / Steam Heating

-

Motor:

-

Siemens Motor

-

Layer:

-

2-3 Layers

-

Machine Type:

-

Dispersion Blender Mixer Machine

-

Control:

-

PLC+ Touch Screen / Button control

-

Homogening speed:

-

0-3600 R/min

-

Stirrer typ:

-

High Speed Homogenizer

-

Advantage:

-

Longer Shelf Life

-

Capacity:

-

50L-2000L

Products Description

150L Cosmetics manufacturing equipment Emulsifier Snail Slime Making Machine Cosmetic Cream Making Machine

Product Details

* High speed vacuum emulsifying mixer homogenizer .might mixing and disperse viscously. Solid and liquid raw material can dissolve material which is hard to dissolve such as AES, AESA LSA during liquid production which can save energy consumption and shorten production the and shorten production period.

* Cream mixer mixing tank main adopts stepless timing device which reduce babble occur under low temperature and high viscosity condition less air bubble will be formed to produce liquid washing products.

* Finished products can be discharged by Disc-valve or suitable to all liquid wash products.

* Cream mixer mixing tank main adopts stepless timing device which reduce babble occur under low temperature and high viscosity condition less air bubble will be formed to produce liquid washing products.

* Finished products can be discharged by Disc-valve or suitable to all liquid wash products.

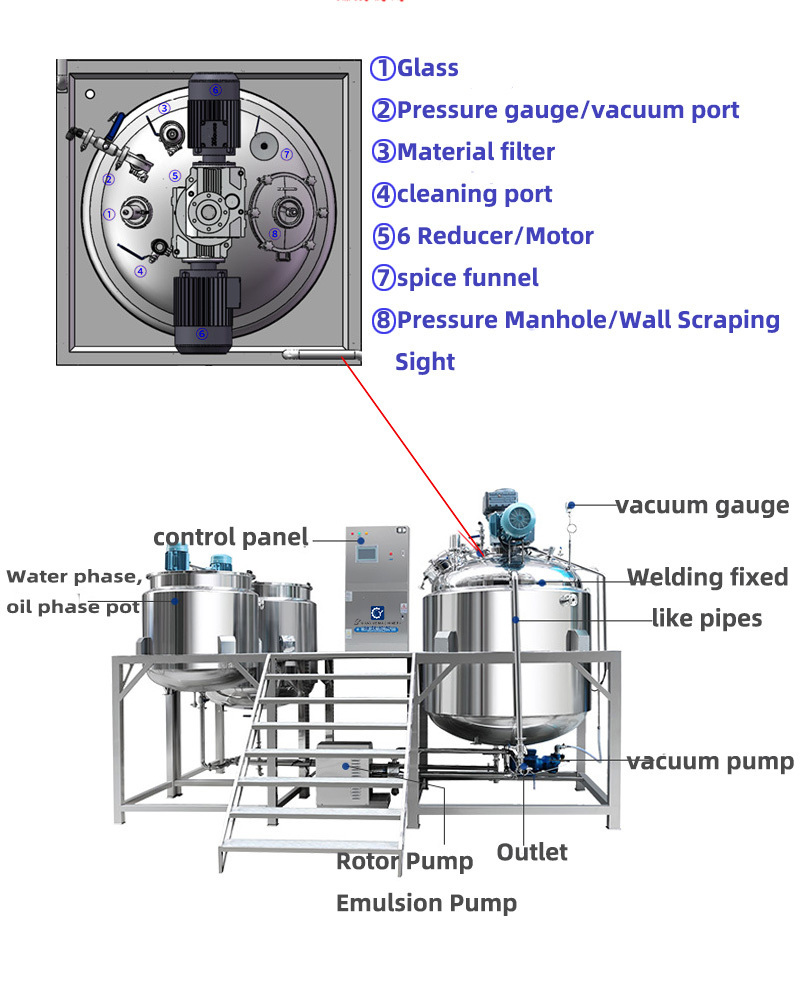

Composition Of Emulsifying Pot

RHJ vacuum emulsifying mixer mixing tank is professionally designed according to the chemical manufacturing process of cosmetics and food etc. products through introducing advanced technology from abroad. The cream mixing machine unit is composed of pre-treating boiler, vacuum emulsifying and blending boiler, vacuum pump, hydraulic system, dumping system, electric control system and work platform etc. The machine unit is featured by simple operation, stable performance, good homogenizing performance, high production efficiency, convenient cleaning, reasonable structure, small land area and high automatic degree etc.

Product Paramenters

|

Main pot

|

Water pot

|

Oil pot

|

Main pot power

|

|

Hydraulic System

|

Vacuum pump power(Kw)

|

||

|

Volume(L)

|

|

|

Wall scraping

|

Homogenizer

|

|

|

||

|

5L

|

|

|

0.18

|

1.1

|

0.75

|

0.55

|

||

|

10L

|

8

|

5

|

0.18

|

1.1

|

0.75

|

0.75

|

||

|

30L

|

18

|

10

|

0.37

|

1.5

|

0.75

|

0.75

|

||

|

50L

|

40

|

25

|

0.75

|

4-7.5

|

1.5

|

1.5

|

||

|

100L

|

80

|

50

|

1.5

|

4-7.5

|

1.5

|

1.5

|

||

|

200L

|

170

|

100

|

2.2

|

7.5-11

|

1.5

|

2.2

|

||

|

300L

|

250

|

150

|

2.2

|

7.5-11

|

1.5

|

2.2

|

||

|

500L

|

420

|

250

|

4

|

11

|

1.5

|

2.2

|

||

|

1000L

|

820

|

500

|

5.5

|

5

|

2.2

|

3

|

||

Suitable For

Hot Searches